Introduction

For electronic hobbyists, batch assembly projects offer an exciting way to dive into the world of electronics, from crafting basic circuits to tackling intricate printed circuit board (PCB) designs. These projects not only build technical skills but also foster creativity through hands-on learning. Whether you are exploring DIY circuit projects or aiming for advanced hobbyist projects, batch assembly provides a structured approach to producing multiple units efficiently. This article covers essential concepts, practical techniques, and actionable steps for electronics project ideas, guiding hobbyists through the process of learning electronics and mastering PCB assembly projects. With a focus on practical application, we aim to equip you with the knowledge to start small and scale up to complex boards with confidence.

What Is Batch Assembly and Why It Matters

Batch assembly in electronics refers to the process of assembling multiple units of a circuit or PCB design in a single production run. This method contrasts with one-off prototyping by focusing on efficiency and consistency across several identical or similar units. For hobbyists, batch assembly is a valuable skill as it mirrors real-world manufacturing processes while allowing experimentation with electronics project ideas on a larger scale. It matters because it reduces time per unit, minimizes errors through repetition, and prepares hobbyists for advanced hobbyist projects where scalability is key. Moreover, it offers a practical way to share or sell DIY circuit projects with friends or small communities, turning a hobby into a potential venture. Understanding batch assembly also deepens one's grasp of learning electronics by exposing common challenges in replication and quality control.

Technical Principles of Batch Assembly in Electronics

Batch assembly relies on systematic planning and execution to ensure each unit meets the desired functionality. At its core, the process involves designing a circuit or PCB, sourcing components, and assembling multiple copies using consistent methods. For simple DIY circuit projects, hobbyists often use breadboards or perfboards, manually placing components like resistors and capacitors. As projects evolve into advanced hobbyist projects, PCB assembly projects become necessary, requiring a schematic design and layout to be replicated across several boards.

One key principle is repeatability. Each unit must be identical, which demands precision in component placement and soldering. Standards like IPC-A-600K, which outlines acceptability criteria for printed boards, provide guidelines for ensuring uniformity even at a hobbyist level. Another principle is component sourcing. Batch assembly requires bulk purchasing of parts to maintain consistency, avoiding variations that could affect performance. For complex boards, surface-mount technology (SMT) may be used, necessitating tools like stencils for solder paste application, aligning with standards such as IPC J-STD-005 for soldering materials.

Thermal management during assembly is also critical, especially for advanced projects. Overheating components during soldering can lead to failures, so hobbyists must follow guidelines from IPC J-STD-020E for moisture sensitivity and reflow processes. These principles ensure that whether working on simple circuits or intricate PCB assembly projects, the outcome remains reliable across all units.

Related Reading: Designing for Batch Assembly: Best Practices for Component Placement

Practical Steps for Batch Assembly Projects

Starting with Simple DIY Circuit Projects

For beginners learning electronics, starting with small batch assembly projects is ideal. Choose a basic circuit, such as an LED blinker using a 555 timer IC. Gather components for at least five units to practice consistency. Use a breadboard initially to test the design before moving to a soldered perfboard. Document each step, noting component values and placement, to ensure repeatability. Hand-soldering works well at this stage, but maintain a steady hand to avoid cold joints, adhering to basic soldering practices outlined in IPC J-STD-001 for electronic assemblies.

Related Reading: Upgrading Your Home Batch Assembly Setup for Improved Efficiency

Scaling to PCB Assembly Projects

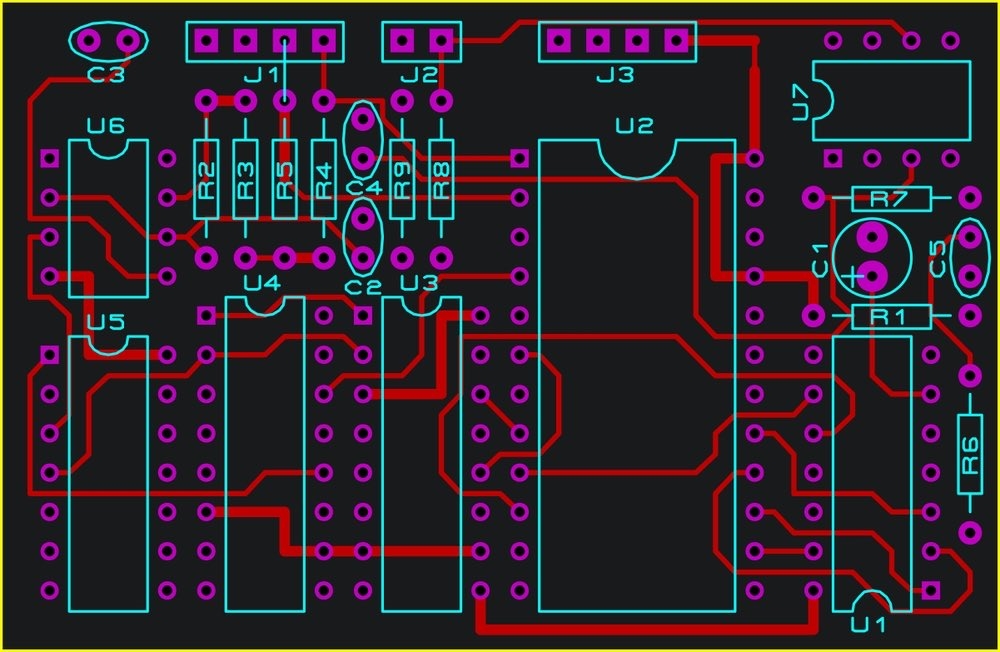

Once comfortable with simple circuits, transition to PCB assembly projects for more advanced hobbyist projects. Begin by designing a schematic using free software tools available to hobbyists. Convert the schematic into a PCB layout, ensuring traces are wide enough for current demands as per IPC-2221 standards for design. Order or etch multiple boards for batch production. Prepare a bill of materials (BOM) to source identical components for all units. Use a stencil for solder paste if dealing with SMT parts, and consider a reflow oven or hot air station for assembly. Test each board post-assembly with a multimeter to verify connections.

Managing Batch Assembly Challenges

Batch assembly introduces challenges like component mismatches and assembly errors. To mitigate these, create a checklist for each step, from component placement to final testing. For DIY circuit projects, label components clearly to avoid mix-ups. In PCB assembly projects, use automated pick-and-place techniques if possible, or maintain a steady workflow for manual placement. Regularly inspect boards for defects, referencing acceptability criteria from IPC-A-600K. If soldering issues arise, rework them promptly using proper desoldering tools to prevent board damage.

Tools and Equipment for Efficiency

Invest in basic tools to streamline batch assembly. A soldering iron with adjustable temperature is essential for both simple and advanced projects. For PCB assembly projects, a magnifying glass or microscope helps with small components. Tweezers and a solder wick are useful for precise work and error correction. As you progress in learning electronics, consider a hot air rework station for SMT components. Keep your workspace organized with component storage bins to speed up assembly across multiple units.

Insights for Advanced Hobbyist Projects

For those ready to push boundaries, advanced hobbyist projects in batch assembly can involve multilayer PCBs or microcontroller-based designs. Start with a project like a custom IoT device, assembling ten units for testing and distribution. Multilayer boards require attention to layer alignment and via placement, following design standards like IPC-6012E for rigid printed boards. Incorporate microcontrollers such as those from the AVR or ARM family, ensuring firmware is identical across units for consistency. Batch assembly at this level may also involve programming each unit, so use a programmer tool to upload code efficiently. Test each board for functionality, focusing on signal integrity and power distribution. These projects not only refine technical skills but also simulate small-scale production environments, offering deep insights into electronics project ideas.

Conclusion

Batch assembly projects provide a structured path for electronic hobbyists to grow from simple DIY circuit projects to complex PCB assembly projects. By understanding core principles like repeatability and thermal management, and applying practical steps such as checklists and proper tooling, hobbyists can achieve consistent results across multiple units. Whether you are just starting with learning electronics or diving into advanced hobbyist projects, batch assembly builds both skill and confidence. Embrace the process, adhere to industry standards, and watch your electronics project ideas come to life in batches that reflect precision and creativity.

FAQs

Q1: What are some beginner-friendly electronics project ideas for batch assembly?

A1: For those learning electronics, start with simple projects like LED arrays or basic timers using a 555 IC. Assemble five to ten units on breadboards or perfboards to practice consistency. Focus on sourcing identical components and documenting each step to ensure uniformity. These small batch projects build foundational skills before moving to more complex designs.

Q2: How can I ensure consistency in DIY circuit projects during batch assembly?

A2: Consistency in DIY circuit projects comes from detailed planning. Create a clear schematic and checklist for component placement. Use identical parts for each unit and test every circuit after assembly with a multimeter. Following basic soldering guidelines, like those in industry standards, helps avoid errors across batches.

Q3: What tools are essential for advanced hobbyist projects in PCB assembly?

A3: Advanced hobbyist projects require precise tools for PCB assembly projects. A temperature-controlled soldering iron, hot air rework station, and magnifying glass are critical for handling small components. Tweezers and desoldering tools aid in corrections. Organized storage for components also speeds up the batch process significantly.

Q4: Why is batch assembly important for learning electronics as a hobbyist?

A4: Batch assembly enhances learning electronics by teaching efficiency and repeatability. Producing multiple units exposes common errors and solutions, mirroring real-world manufacturing. It builds problem-solving skills and prepares hobbyists for scaling up to complex projects, making it a practical step in mastering electronics.

References

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

IPC J-STD-001H — Requirements for Soldered Electrical and Electronic Assemblies. IPC, 2020.

IPC J-STD-005A — Requirements for Soldering Pastes. IPC, 2012.

IPC J-STD-020E — Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices. IPC, 2014.

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-2221B — Generic Standard on Printed Board Design. IPC, 2012.