Introduction

Printed Circuit Board (PCB) depaneling is a critical step in electronics manufacturing, where individual boards are separated from a larger panel after assembly. Selecting the right PCB depaneling method impacts production efficiency, board quality, and overall cost. Electrical engineers must evaluate various techniques, such as V-scoring, stamp hole, routing, and laser cutting, to ensure compatibility with design requirements and manufacturing goals. This article provides a detailed PCB depaneling methods comparison, explores depaneling cost analysis, and offers guidance on depaneling equipment selection. By understanding the strengths and limitations of each approach, including laser versus router depaneling and V-score versus stamp hole cost, engineers can make informed decisions to optimize their processes while adhering to industry standards.

What Is PCB Depaneling and Why It Matters

PCB depaneling refers to the process of separating individual circuit boards from a multi-board panel used during manufacturing. Panels allow for efficient handling and assembly of multiple boards at once, reducing production time. However, separating these boards without causing damage to components or traces is essential. Poor depaneling can lead to mechanical stress, cracked solder joints, or compromised board integrity, directly affecting product reliability.

For electrical engineers, choosing the appropriate depaneling method is vital for maintaining design specifications and meeting quality standards like those outlined in IPC-6012E. The decision influences production speed, material waste, and overall expenses. With various techniques available, understanding their technical implications ensures that the selected method aligns with both project needs and manufacturing capabilities.

Technical Principles of PCB Depaneling Methods

This section examines the core principles behind common depaneling techniques, providing a foundation for comparison.

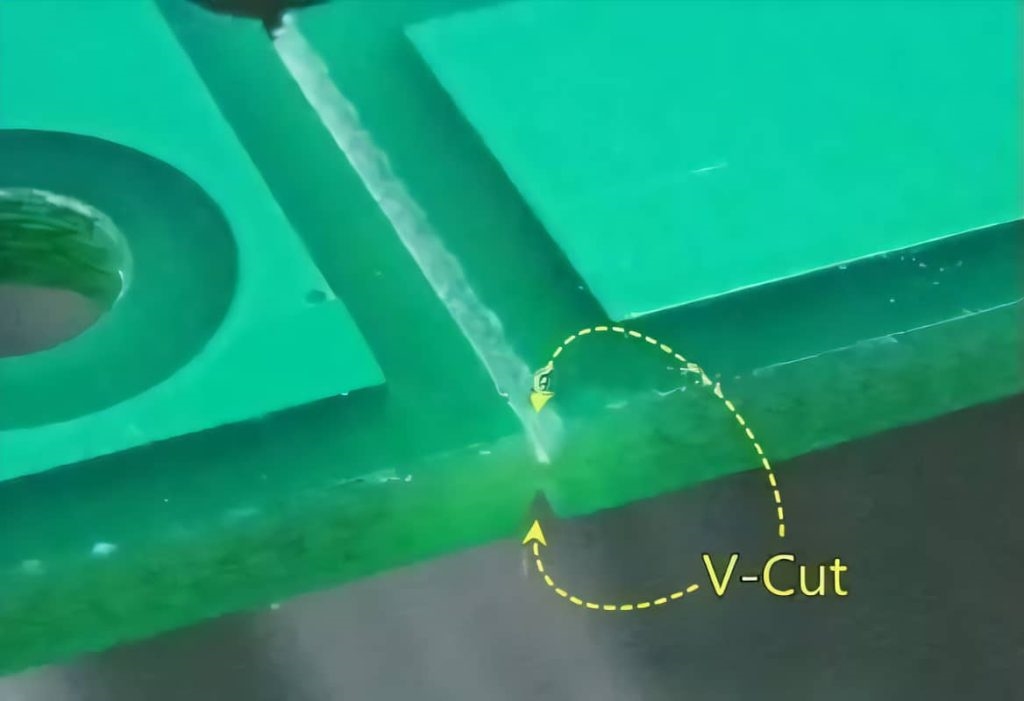

V-Scoring

V-scoring involves creating V-shaped grooves on both sides of the PCB panel along separation lines. These grooves weaken the material, allowing manual or automated breaking along the scored lines. This method suits simple, straight cuts and works well with standard FR-4 materials. However, it can induce stress near components if not designed per guidelines in IPC-A-600K, which specifies acceptability criteria for printed boards.

Stamp Hole (Mouse Bites)

Stamp hole depaneling uses a series of small, perforated holes along the board edges, often called mouse bites. These holes create a breakaway point for separation. This technique is useful for irregular board shapes or when V-scoring is impractical. It minimizes stress compared to V-scoring but may leave rough edges, requiring additional finishing to meet quality standards.

Related Reading: Understanding Mouse Bites: A Key to Efficient PCB Manufacturing

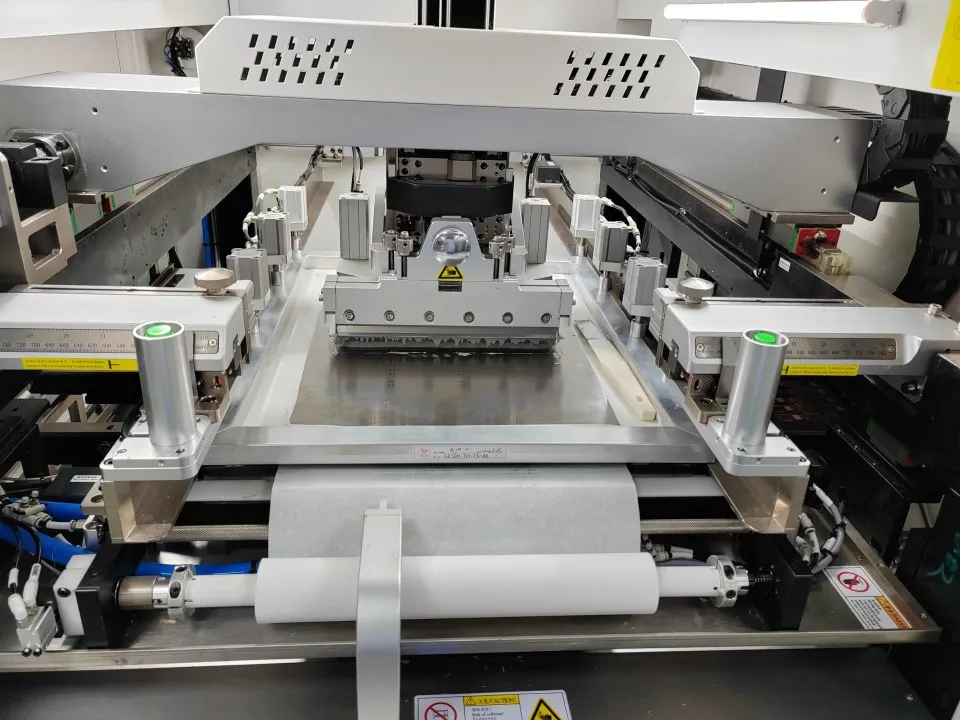

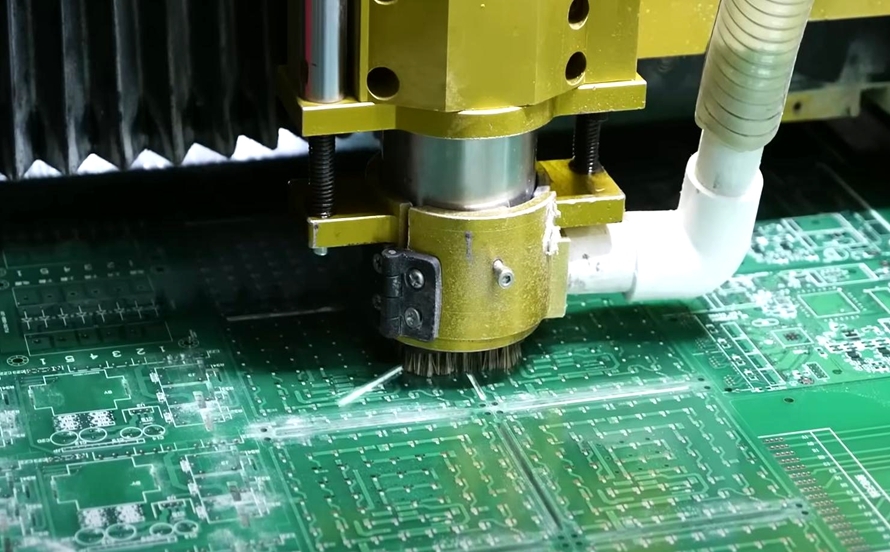

Router Depaneling

Routing employs a high-speed rotating bit to cut through the PCB material along predefined paths. This method offers precision for complex board geometries and densely populated designs. It produces clean edges but generates dust and requires fixturing to hold the panel. Engineers must consider vibration and heat effects on nearby components during routing.

Laser Depaneling

Laser cutting uses focused light beams to vaporize material along separation lines. This non-contact method provides high precision and is ideal for intricate designs or thin, flexible boards. It avoids mechanical stress but can cause thermal effects if not controlled. Laser depaneling aligns with modern manufacturing needs for accuracy, though equipment costs are higher.

Comparison of PCB Depaneling Methods

A PCB depaneling methods comparison requires evaluating factors like precision, stress on components, suitability for design complexity, and scalability. Below is a structured analysis in list form.

- V-Scoring: Precision: Moderate; Stress on components: High if near components; Design complexity: Low (straight cuts); Scalability: High.

- Stamp Hole: Precision: Low; Stress on components: Moderate; Design complexity: Moderate; Scalability: Moderate.

- Router Depaneling: Precision: High; Stress on components: Low with proper setup; Design complexity: High; Scalability: Moderate.

- Laser Depaneling: Precision: Very high; Stress on components: Very low; Design complexity: Very high; Scalability: High with investment.

Related Reading: Router Depaneling: The Go To Method for Intricate PCB Designs?

Laser vs Router Depaneling

When comparing laser versus router depaneling, precision and stress are key differentiators. Laser cutting excels in accuracy and minimizes mechanical stress, making it suitable for fragile or high-density boards. However, thermal effects must be managed to prevent damage to nearby areas. Router depaneling offers clean cuts and versatility for various materials but introduces vibration risks. Engineers must weigh these factors based on board specifications and production volume.

V-Score vs Stamp Hole Cost

Analyzing V-score versus stamp hole cost reveals distinct economic considerations. V-scoring is generally more cost-effective due to simpler tooling and faster processing for straight-line separations. It aligns with high-volume production where design complexity is minimal. Stamp hole depaneling, while slightly more expensive due to additional drilling steps, offers flexibility for non-linear cuts. Cost differences often depend on panel layout and the need for post-separation finishing.

Related Reading: Choosing the Right PCB Depaneling Method: A Comprehensive Comparison

Depaneling Cost Analysis

Depaneling cost analysis involves assessing equipment, labor, material waste, and maintenance expenses. Below is a breakdown of cost factors for each method.

- V-Scoring: Low initial setup cost and minimal equipment needs. Labor costs are low for manual separation, though automation may add expense. Material waste is negligible.

- Stamp Hole: Moderate setup cost due to precise drilling requirements. Labor costs are similar to V-scoring, with potential for higher waste from rough edges.

- Router Depaneling: Higher equipment cost for cutting tools and fixturing. Maintenance of bits and dust management systems adds to expenses. Labor costs vary with automation level.

- Laser Depaneling: High initial investment for equipment. Operating costs include power consumption and periodic maintenance. Minimal material waste and low labor needs can offset long-term expenses.

Engineers must balance these costs against production volume and quality requirements. High-volume runs may justify investment in laser systems, while smaller batches might favor V-scoring for cost efficiency.

Depaneling Equipment Selection Guidelines

Choosing the right depaneling equipment selection criteria involves aligning tools with project needs and manufacturing constraints. Consider the following factors.

Board Design and Material

Complex geometries or flexible substrates often require laser or router systems for precision. Standard rigid boards with simple layouts can use V-scoring or stamp hole methods effectively. Material thickness and composition also influence tool choice, as outlined in IPC-6012E for rigid board performance.

Production Volume

High-volume production benefits from automated systems like laser or advanced routing setups to ensure consistency and speed. Low-volume or prototype runs may prioritize cost-effective manual or semi-automated tools for V-scoring.

Quality and Stress Requirements

For densely populated boards or sensitive components, non-contact methods like laser cutting reduce stress risks. Router systems with proper fixturing can also minimize damage if vibration is controlled. Standards such as IPC-A-600K provide benchmarks for acceptable board quality post-depaneling.

Budget Constraints

Initial equipment costs and long-term maintenance must fit within budget limits. While laser systems require significant upfront investment, they may lower per-unit costs in large-scale operations. Simpler methods like V-scoring offer immediate savings for constrained budgets.

Best Practices for Optimizing Depaneling Processes

Implementing effective depaneling starts with design and extends to execution. Follow these best practices to enhance outcomes.

- Incorporate depaneling considerations during the design phase, ensuring breakaway lines avoid critical components or traces.

- Use panelization software to optimize layout, reducing material waste and aligning with the chosen method.

- Adhere to industry standards like IPC-A-600K for inspecting board edges after separation to ensure quality.

- Test depaneling setups on prototype panels to identify stress points or tooling issues before full production.

- Maintain equipment regularly to prevent wear that could compromise cut quality or board integrity.

Conclusion

Selecting the appropriate PCB depaneling method requires a thorough understanding of design needs, production goals, and cost implications. This PCB depaneling methods comparison highlights the unique advantages of V-scoring, stamp hole, routing, and laser cutting, while depaneling cost analysis underscores the economic factors at play. Whether evaluating laser versus router depaneling or V-score versus stamp hole cost, engineers must prioritize precision, stress management, and scalability. Proper depaneling equipment selection, guided by industry standards, ensures reliable outcomes and efficient manufacturing. By applying these insights, electrical engineers can achieve optimal results tailored to their specific requirements.

FAQs

Q1: What factors should influence PCB depaneling methods comparison for high-density boards?

A1: For high-density boards, prioritize methods like laser or router depaneling to minimize mechanical stress on components. Laser cutting offers superior precision for intricate layouts, while routing provides clean edges if vibration is controlled. Consider material type and component placement to avoid damage near separation lines, ensuring compliance with quality standards.

Q2: How does depaneling cost analysis impact small-scale versus large-scale production?

A2: Depaneling cost analysis reveals that small-scale production benefits from low-cost methods like V-scoring due to minimal equipment needs. Large-scale runs justify investment in automated laser systems, reducing per-unit costs and labor. Balancing initial expenses with long-term savings is key to optimizing budgets across production scales.

Q3: What are the key differences in laser vs router depaneling for flexible PCBs?

A3: In laser versus router depaneling, laser cutting stands out for flexible PCBs due to its non-contact nature, avoiding mechanical stress. Router depaneling can work but risks tearing or deforming thin materials if not precisely controlled. Laser offers finer cuts, though thermal effects must be managed carefully.

Q4: How does depaneling equipment selection affect overall manufacturing efficiency?

A4: Depaneling equipment selection directly impacts manufacturing efficiency by determining separation speed and quality. Automated laser or router systems enhance throughput for high volumes, while manual V-scoring suits smaller runs. Proper equipment reduces rework, minimizes waste, and ensures consistent board integrity, streamlining the production process.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.