Introduction

In the realm of Printed Circuit Board (PCB) assembly, thorough testing is essential to guarantee product reliability and functionality. As an assembly engineer, I have witnessed the evolution of testing methodologies firsthand. The fundamental choice often lies between traditional manual inspection and the advanced capabilities of automated systems like In Circuit Test (ICT) using specialized fixtures. This article will make a clear case for automation, highlighting its critical benefits over manual approaches in ensuring high-quality board assemblies.

The Challenges of Manual PCB Testing

Before the widespread adoption of automated equipment, manual testing was the primary method for verifying PCB assembly quality. This often involved visual inspection by skilled technicians using microscopes, and continuity checks with multimeters. While experienced human eyes can identify many obvious defects, this approach presents significant challenges.

Manual testing is inherently slow and labor intensive. Each board assembly requires individual attention, leading to bottlenecks in production lines. Furthermore, human inspection is prone to error. Fatigue, distraction, or subtle variations in components can lead to missed defects. The consistency of results can vary greatly from one inspector to another, making it difficult to maintain uniform quality standards. Subjectivity in defect identification can result in unnecessary rework or, worse, the shipment of faulty products. Such inconsistencies directly impact manufacturing efficiency and increase overall costs due in part to higher scrap rates and warranty claims.

Introducing ICT Test Fixtures and Automated Equipment

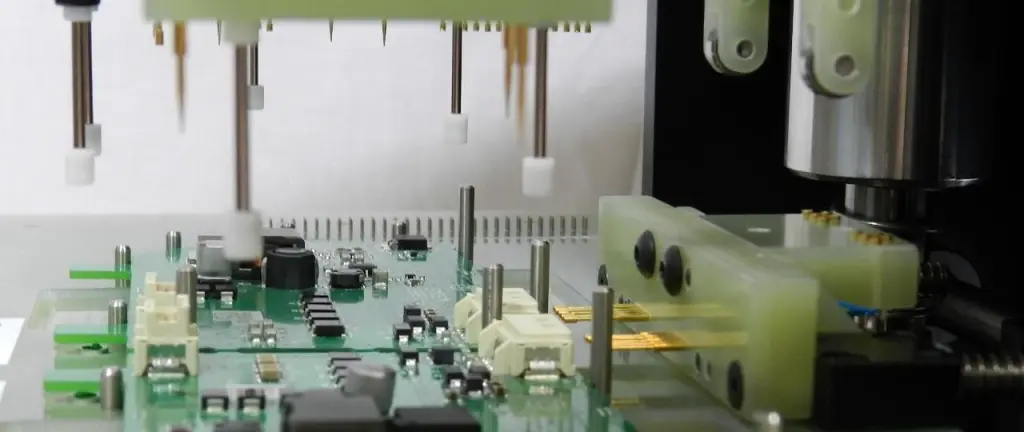

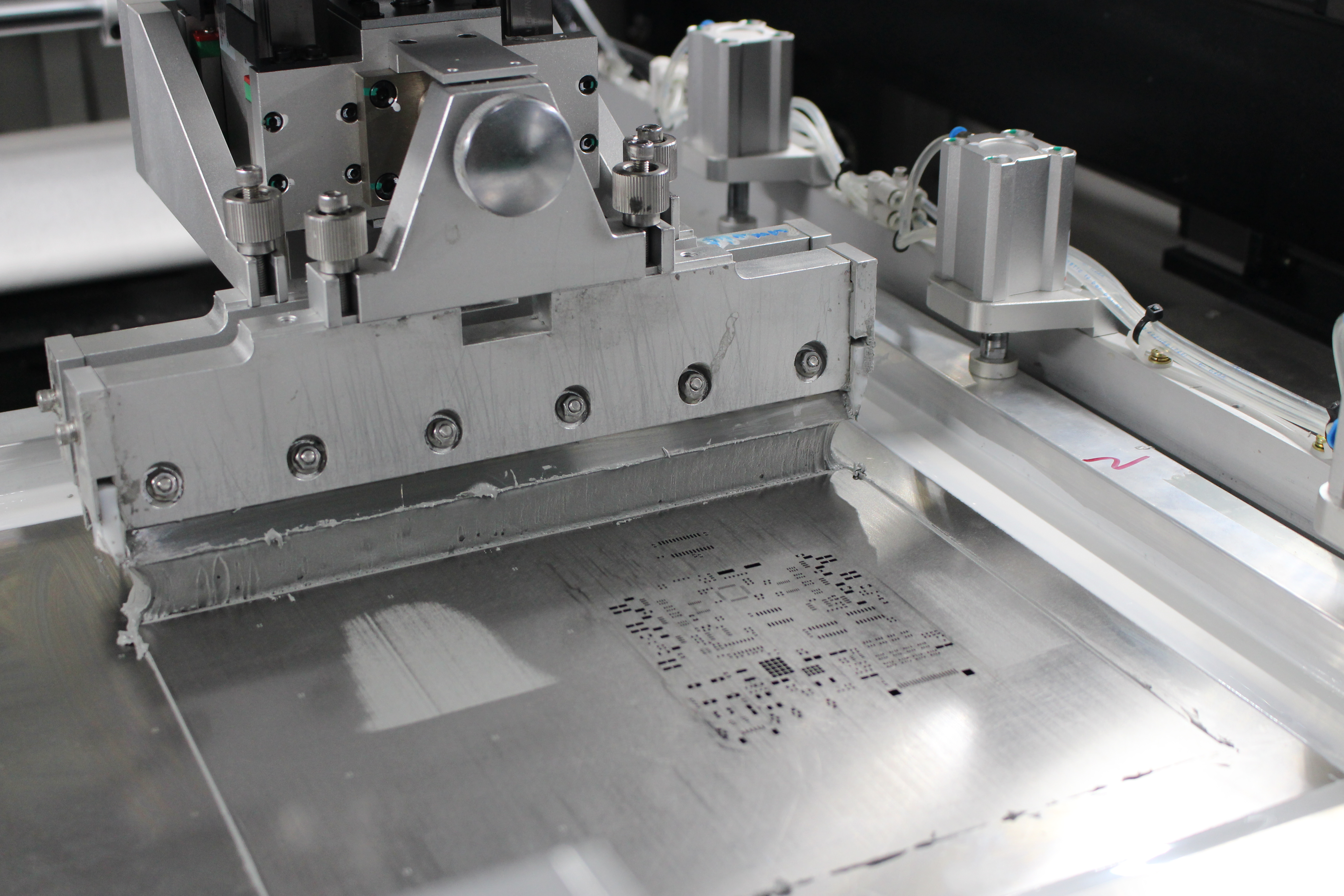

The advent of ICT Test Fixtures marked a significant leap forward in PCB assembly testing. This method moves away from manual processes towards a highly efficient, automated approach. An ICT Test Fixture is a custom engineered interface that provides precise physical contacts to specific test points on a board assembly. These fixtures are integrated with sophisticated automated equipment, forming a complete testing system.

The automated equipment, controlled by an automation computer, systematically performs electrical measurements and logic measurements across the entire board. This automation eliminates the human variability inherent in manual testing. It ensures that every board assembly undergoes the same rigorous set of checks, providing consistent and repeatable results. The core strength of ICT lies in its ability to isolate and identify individual component failures or manufacturing defects at high speed and with exceptional accuracy.

Technical Advantages of Automation: Electrical and Logic Measurements

Automated equipment, specifically ICT systems, offers profound technical advantages through its precise electrical measurements and logic measurements. These capabilities are far beyond what manual methods can consistently achieve.

The system uses its array of physical contacts to apply controlled currents and voltages to individual nodes on the PCB. It then measures the resulting electrical parameters, such as resistance, capacitance, and inductance, across components. For instance, the automated equipment can verify if a resistor’s value falls within its specified tolerance or if a capacitor exhibits the correct capacitance. These electrical measurements are critical for confirming the correct placement and functionality of passive components.

Beyond passive components, modern ICT systems are also capable of performing logic measurements. This involves verifying the correct operation of digital integrated circuits (ICs). By applying specific input patterns to an IC's pins via the physical contacts and monitoring the output responses, the automation computer can determine if the IC is functioning as designed. This is crucial for detecting misoriented or faulty digital components. The speed at which these measurements are taken, often thousands per second, allows for comprehensive testing of complex board assemblies in a matter of seconds.

The precision and repeatability of these measurements, driven by the automation computer, ensure that even subtle deviations from expected values are detected. This detailed diagnostic capability provides valuable feedback for process control and quality improvement in the manufacturing line.

The Role of Physical Contacts in Automated Testing

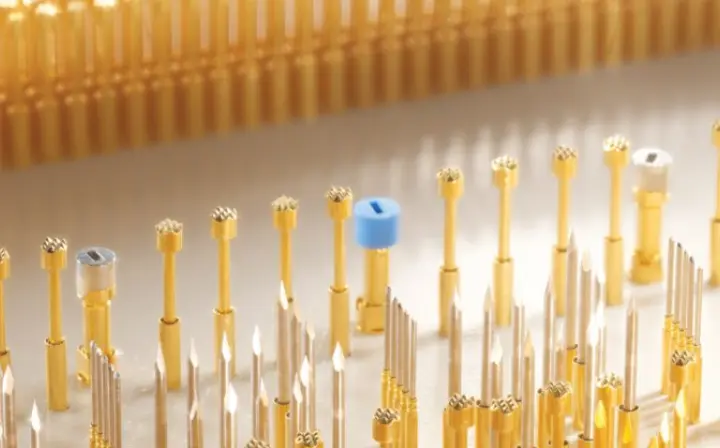

The success of ICT Test Fixtures and automated testing hinges on the integrity and accuracy of their physical contacts. These contacts are typically spring-loaded probes, often called pogo pins, meticulously arranged within the fixture. Each pogo pin is precisely positioned to connect with a specific test point or pad on the board assembly.

The reliability of these physical contacts is paramount. A well designed fixture ensures that every pin makes solid and consistent contact with its target. This is achieved through careful mechanical design and alignment of the fixture to the PCB. Poor contact can lead to "false failures," where a defect is reported when none exists, or, conversely, "escapes," where a real defect goes undetected. To prevent this, fixtures require regular maintenance, including cleaning and replacement of worn or bent probes.

The ability to establish multiple, simultaneous physical contacts across the entire board assembly is what gives ICT its comprehensive testing power. Instead of checking one point at a time manually, the automated equipment can access hundreds or even thousands of test points concurrently. This parallel testing capability dramatically reduces test time while increasing the depth of fault detection. Adherence to industry guidelines for test point accessibility, as detailed in standards like IPC-2221B, "Generic Standard on Printed Board Design," is essential during the PCB design phase to enable effective physical contact by the fixture.

Related Reading: What You Need to Know Before Designing an ICT Test Fixture

Making the Case for Automation: Efficiency, Accuracy, and Cost Savings

The transition from manual testing to automated equipment, especially ICT Test Fixtures, represents a compelling case for automation in PCB assembly. The benefits span across efficiency, accuracy, and significant cost savings.

Enhanced Efficiency

Automated systems can test board assemblies in seconds, a stark contrast to the minutes or even hours required for thorough manual inspection. This drastically increases throughput, allowing manufacturing lines to handle higher volumes without additional labor. The automation computer rapidly processes electrical measurements and logic measurements, generating instant pass or fail reports.

Unparalleled Accuracy and Repeatability

The precision of automated equipment virtually eliminates human error. Every test is performed identically, ensuring consistent and repeatable results across all board assemblies. This objectivity removes subjectivity from the testing process, leading to more reliable defect detection and better overall product quality.

Superior Defect Coverage

ICT, through its numerous physical contacts, can detect a wide range of manufacturing defects that are difficult or impossible to find manually. These include shorts, opens, incorrect component values, missing components, and misoriented parts. The system provides exact fault location, accelerating the repair process.

Significant Cost Savings

While the initial investment in automated equipment and ICT Test Fixtures can be higher, the long term savings are substantial. Early defect detection minimizes rework costs later in the production cycle. Reduced scrap rates, improved product reliability, and fewer warranty claims contribute directly to the bottom line. Furthermore, the efficiency gains reduce labor costs associated with testing. This aligns with the quality management principles outlined in standards such as ISO 9001:2015, "Quality Management Systems," which emphasizes process efficiency and customer satisfaction.

Related Reading: Vacuum vs. Pneumatic ICT Test Fixtures: Which is Right for Your Production Line?

Conclusion

The shift from manual testing to automated equipment, particularly ICT Test Fixtures, is not merely a technological upgrade but a fundamental improvement in the quality control paradigm for PCB assembly. By leveraging precise electrical measurements, sophisticated logic measurements, and reliable physical contacts managed by an automation computer, ICT offers unparalleled efficiency, accuracy, and defect coverage. While manual methods played their role historically, the demands of modern electronics manufacturing necessitate the speed, consistency, and diagnostic power that only automation can provide. For any manufacturer committed to producing high-quality, reliable board assemblies, making the case for automation is a clear imperative.

FAQs

Q1: Why is automation preferred over manual testing for PCB assembly?

A1: Automation, particularly with ICT Test Fixtures, offers superior speed, accuracy, and repeatability compared to manual testing. Automated equipment, guided by an automation computer, eliminates human error, quickly performs complex electrical and logic measurements, and provides objective defect detection. This leads to higher throughput, improved product quality, and significant long-term cost savings in PCB assembly.

Q2: What kinds of measurements can automated equipment perform?

A2: Automated equipment, like an ICT system, can perform precise electrical measurements such as resistance, capacitance, and inductance to verify component values. It also conducts logic measurements to confirm the correct functionality and orientation of digital integrated circuits. These comprehensive tests are enabled by reliable physical contacts between the fixture and the board assembly.

Q3: How do physical contacts contribute to automated testing effectiveness?

A3: Physical contacts, typically spring-loaded pins in an ICT Test Fixture, are crucial for automated testing. They establish precise, simultaneous connections to numerous test points on the board assembly. This allows the automated equipment to perform rapid electrical and logic measurements across the entire board, ensuring comprehensive defect detection and maximizing the efficiency of the automation computer.

Q4: What role does an automation computer play in ICT testing?

A4: The automation computer is the control center for ICT Testing. It manages the entire test sequence, applies test signals through the fixture's physical contacts, reads the electrical measurements and logic measurements, and compares them against predefined specifications. The computer also analyzes test results, generates detailed fault reports, and facilitates data collection for process improvement, making the testing process efficient and data-driven.

References

IPC-A-610G — Acceptability of Electronic Assemblies. IPC, 2017.

IPC-2221B — Generic Standard on Printed Board Design. IPC, 2012.

J-STD-001G — Requirements for Soldered Electrical and Electronic Assemblies. IPC/JEDEC, 2017.

ISO 9001:2015 — Quality Management Systems. ISO, 2015.