Introduction

For electronic hobbyists, creating a functional printed circuit board often involves separating individual boards from a larger panel, a process known as PCB depaneling. This step is critical to ensure the integrity of each circuit while maintaining precision and avoiding damage to components. Selecting the right PCB depaneling method can be challenging, as it depends on factors like board material, design complexity, and available tools. Whether you are working on a small prototype or a batch of custom designs, understanding various depaneling methods and choosing the best choice for your project is essential. This article explores the technical aspects of PCB depaneling, outlines common methods, and provides practical guidance to help hobbyists achieve clean and effective separations with minimal risk to their boards.

What Is PCB Depaneling and Why It Matters

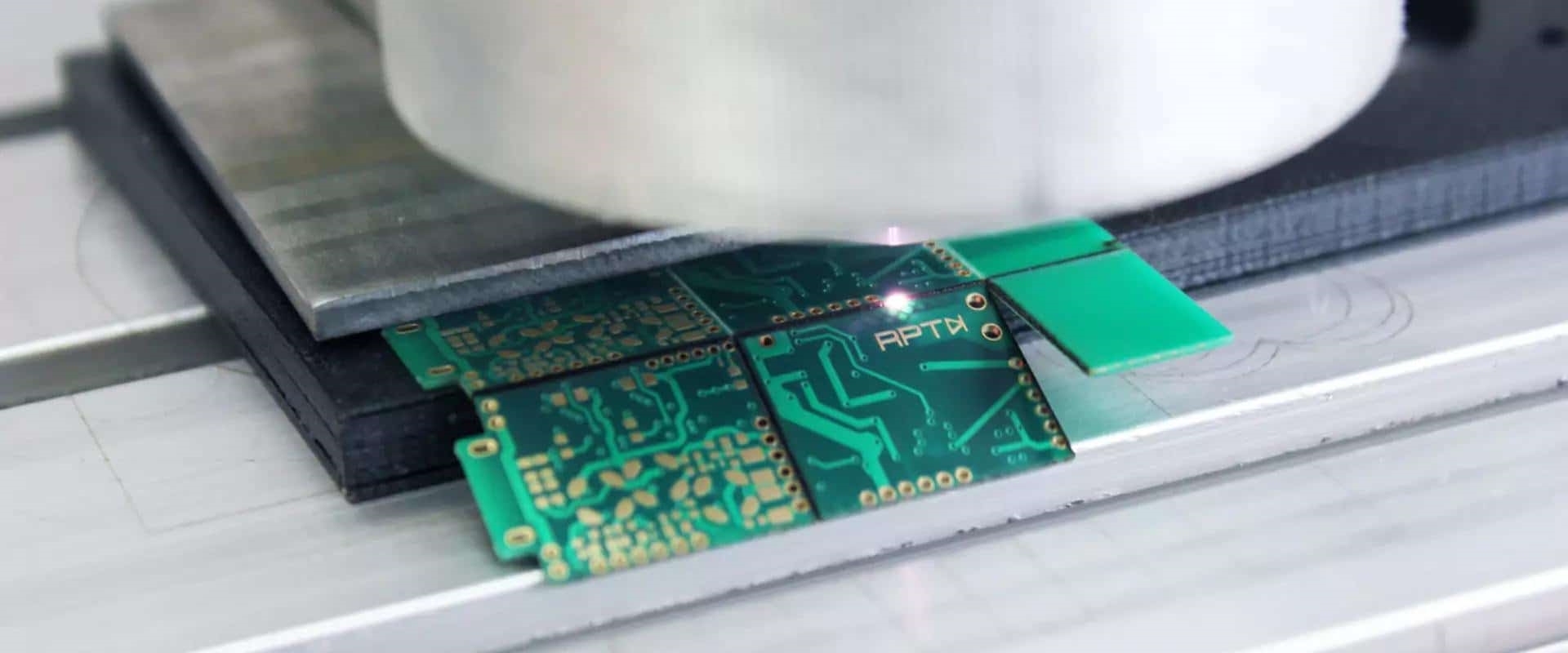

PCB depaneling refers to the process of separating individual printed circuit boards from a larger panel or array after fabrication. During manufacturing, multiple PCBs are often produced on a single panel to optimize space and reduce costs. Once the assembly and testing phases are complete, these boards must be separated for use in final products. For electronic hobbyists, depaneling is a crucial final step in turning a design into a functional device.

The importance of proper depaneling cannot be overstated. Incorrect methods can lead to mechanical stress, cracked solder joints, or damaged traces, rendering a board unusable. Hobbyists often work with limited resources, making it vital to choose a method that balances precision, cost, and accessibility. A poor depaneling choice can also affect the board's reliability in applications, especially for sensitive electronics. By understanding the available methods and their implications, you can ensure the quality of your projects while avoiding costly mistakes.

Technical Principles of PCB Depaneling

Depaneling involves breaking or cutting the connections between individual boards on a panel, which are typically held together by small tabs, scored lines, or other structural features. The primary goal is to separate the boards without inducing stress or damage. Several technical principles govern the process, and understanding these can guide hobbyists in choosing the most suitable method.

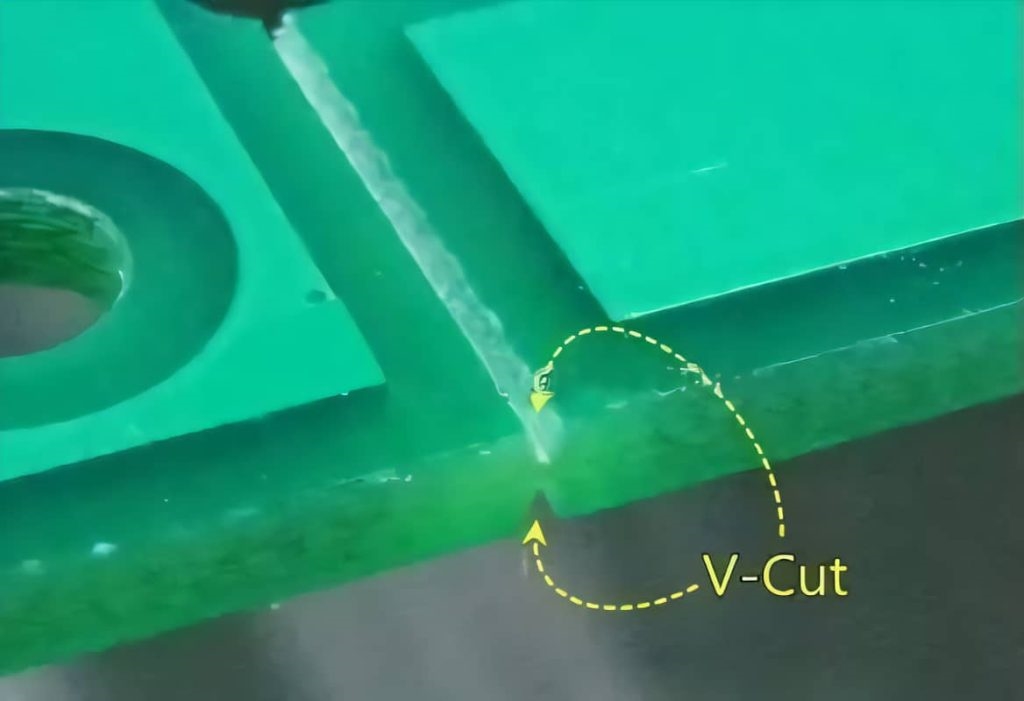

First, the material composition of the PCB plays a significant role. Most hobbyist boards are made of FR-4, a fiberglass-reinforced epoxy laminate, which has specific mechanical properties like tensile strength and brittleness. These properties determine how the board responds to cutting or breaking forces. Second, the design of the panel itself, such as the presence of V-scores or perforated tabs, influences the depaneling approach. V-scores are pre-cut grooves that weaken the material along separation lines, while tabs are small connecting bridges often used with routing.

Another key principle is minimizing stress during separation. Excessive force or improper tools can cause micro-cracks in the board or delaminate layers, compromising structural integrity. Standards like IPC-6012E provide guidelines on acceptable stress levels and board quality post-depaneling. Finally, the proximity of components to separation lines must be considered. Boards with densely populated edges require precise methods to avoid damaging nearby parts.

Common PCB Depaneling Methods for Hobbyists

Manual Depaneling with V-Scores

Manual depaneling is often the simplest and most cost-effective method for hobbyists. It typically involves boards designed with V-scores, which are shallow grooves cut into both sides of the panel. These grooves create a weak point, allowing the board to be snapped apart by hand or with minimal tools. This method requires no specialized equipment, making it ideal for small projects or prototypes.

However, manual depaneling is best suited for simpler designs with straight separation lines. It can introduce stress if not done carefully, potentially leading to cracks. Hobbyists should ensure the panel is supported evenly during separation to distribute force. According to IPC-A-600K, boards separated manually must still meet visual and structural acceptability criteria to ensure reliability.

Scoring and Breaking with Tools

For hobbyists without pre-scored panels, a scoring tool or utility knife can be used to create a groove along the desired separation line. After scoring, the board can be broken along this line. This method offers more control over custom separation paths and is still relatively low-cost. A straight edge or ruler can help maintain accuracy while scoring.

The downside is the risk of uneven cuts or excessive force, which can damage the board. It is also time-consuming for multiple boards. Hobbyists should wear protective gear, as small shards of material may break off during the process.

Handheld Rotary Tools for Routing

Handheld rotary tools, often equipped with small cutting bits, can be used for depaneling through a process called routing. This method involves cutting through tabs or material between boards, offering flexibility for irregular shapes or designs without V-scores. Routing is more precise than manual breaking and suitable for denser boards where components are near edges.

However, rotary tools require a steady hand and practice to avoid veering off course. Dust and debris from cutting can also pose a hazard, so proper ventilation and eye protection are necessary. This method aligns with guidelines in IPC-6012E for ensuring clean edges post-separation.

Shearing with Specialized Cutters

Specialized PCB shearing tools or nippers are designed to cut through small tabs or thin material connecting boards. These tools provide a clean cut with minimal stress, making them a good choice for hobbyists handling small batches. They are particularly effective for panels with perforated tabs, often referred to as mouse bites, which are small drilled holes creating a breakable connection.

While effective, shearing tools are limited to specific panel designs and may not work for thicker boards. Care must be taken to align the cutter precisely to avoid damaging adjacent areas.

Practical Solutions for Choosing the Best PCB Depaneling Method

Assess Your Panel Design

Start by examining the panel layout. If your PCB design includes V-scores, manual depaneling or scoring tools are likely sufficient. For panels with tabs or complex shapes, consider routing with a rotary tool or using shearing cutters. Always check the panel's documentation or design files for separation instructions to avoid unnecessary damage.

Consider Board Material and Thickness

Standard hobbyist boards made of PCB FR-4 are generally compatible with most depaneling methods. However, thicker boards or those with multiple layers may require more robust tools like rotary cutters. Refer to standards like IPC-A-600K for acceptable material conditions after depaneling to ensure your method does not compromise quality.

Evaluate Component Placement

If components are placed close to the panel edges, opt for precise methods like routing or shearing. Manual breaking can exert stress that damages nearby parts. Plan your design with adequate clearance around separation lines to minimize risks, as recommended by industry guidelines.

Balance Cost and Accessibility

Hobbyists often work with limited budgets, so prioritize methods that require minimal investment. Manual depaneling and scoring tools are the most affordable, while handheld rotary tools offer a middle ground between cost and precision. Assess whether the frequency of your projects justifies investing in specialized equipment.

Suggested Reading: Mastering PCB Depaneling: A Step by Step Tutorial

Troubleshooting Common Depaneling Issues

Even with careful planning, hobbyists may encounter issues during PCB depaneling. Here are practical solutions to common problems.

If a board cracks during manual separation, it often indicates uneven force or poor support. Always support the panel on both sides of the separation line using a flat surface or edge. For jagged edges after routing, check the cutting bit for wear and ensure a slow, steady pace. Dust accumulation from cutting can be mitigated by working in a well-ventilated area and using a small brush to clean the board afterward.

When components near edges are damaged, revisit your method choice. Switching to a more controlled approach like shearing can prevent recurrence. Standards such as IPC-6012E emphasize post-depaneling inspection to identify and address defects early.

Conclusion

PCB depaneling is a vital skill for electronic hobbyists aiming to transform panelized designs into functional boards. By understanding the principles behind various methods like manual breaking, scoring, routing, and shearing, you can make an informed decision on the best choice for your project. Consider factors such as panel design, material properties, and component placement to minimize risks and ensure clean separations. With practical guidance and adherence to industry standards, hobbyists can achieve reliable results without compromising board quality. Mastering the art of choosing the right PCB depaneling method will enhance your workflow and elevate the success of your electronic creations.

FAQs

Q1: What is PCB depaneling, and why is it important for hobbyists?

A1: PCB depaneling is the process of separating individual printed circuit boards from a larger panel. For hobbyists, it is crucial because improper separation can damage boards, affecting functionality. Choosing the right method ensures minimal stress on components and traces, preserving the integrity of your project. Understanding depaneling helps avoid costly mistakes in small-scale or prototype work.

Q2: Which PCB depaneling method is the best choice for beginners?

A2: For beginners, manual depaneling with V-scores is often the best choice due to its simplicity and low cost. It requires no specialized tools, just careful snapping along pre-cut grooves. However, ensure even force to avoid cracks. This method suits simple designs and aligns with basic quality checks in industry standards.

Q3: How do I avoid damaging components during PCB depaneling?

A3: To avoid damaging components during depaneling, choose a precise method like routing or shearing, especially if parts are near edges. Plan designs with clearance around separation lines. Support the panel evenly during separation to reduce stress. Following guidelines from standards ensures components remain intact and functional after the process.

Q4: What factors should influence choosing a PCB depaneling method?

A4: When choosing a PCB depaneling method, consider panel design, material thickness, and component placement. Budget and tool accessibility also play a role for hobbyists. Assess whether V-scores or tabs are present, and opt for methods that minimize stress. Matching the method to your project needs ensures clean, effective separation.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.