Introduction

Solder paste printing stands as a foundational process in surface mount technology assembly for printed circuit boards. This critical step directly influences the quality of solder joints, impacting the reliability and functionality of electronic devices. Achieving consistent results requires a deep understanding of solder paste printing techniques and precise control over variables such as squeegee pressure. For electrical engineers, mastering these elements ensures reduced defects and optimized production outcomes. This article explores the intricacies of solder paste printing, focusing on squeegee pressure adjustments and proven techniques to enhance assembly quality. By adhering to industry standards and leveraging practical insights, engineers can address common challenges and improve process efficiency. Join us as we break down the technical principles and best practices that define successful solder paste application in modern electronics manufacturing.

What Is Solder Paste Printing and Why It Matters

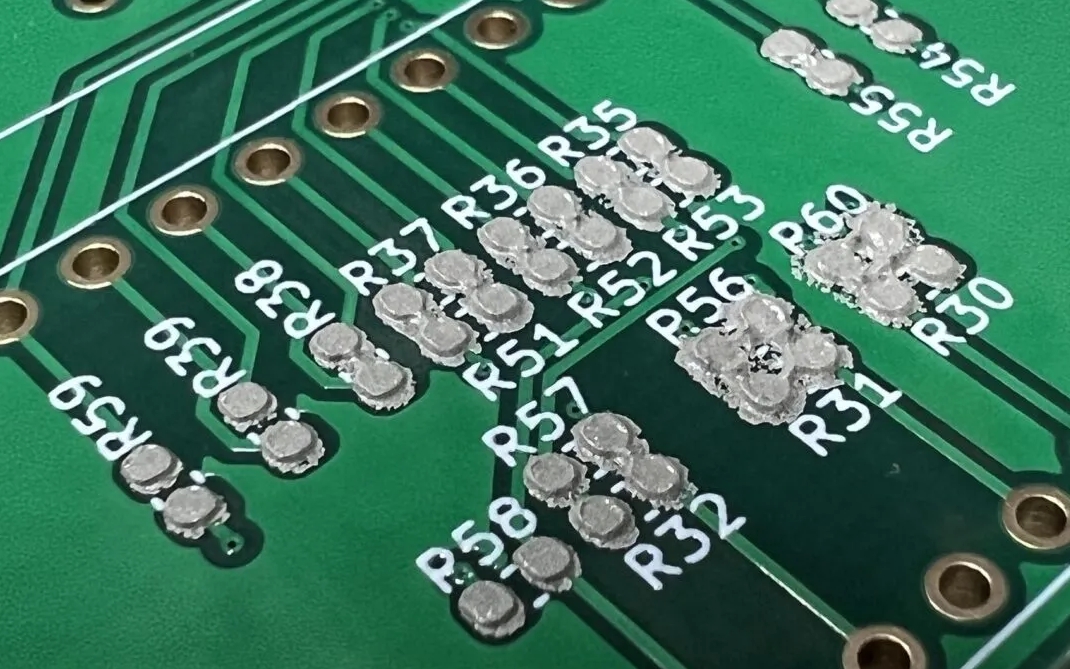

Solder paste printing involves the precise application of a mixture of solder particles and flux onto specific areas of a printed circuit board using a stencil. This process prepares the board for component placement and subsequent reflow soldering, forming reliable electrical connections. It serves as the first step in surface mount assembly, where accuracy determines the success of downstream processes. Poor solder paste printing can lead to defects like insufficient solder, bridging, or misalignment, resulting in costly rework or product failures. For electrical engineers, understanding this process is vital to ensure high yield and meet stringent quality requirements in production. With the increasing complexity of electronic designs, mastering solder paste printing techniques becomes essential to maintain competitive manufacturing standards and deliver robust end products.

Technical Principles of Solder Paste Printing

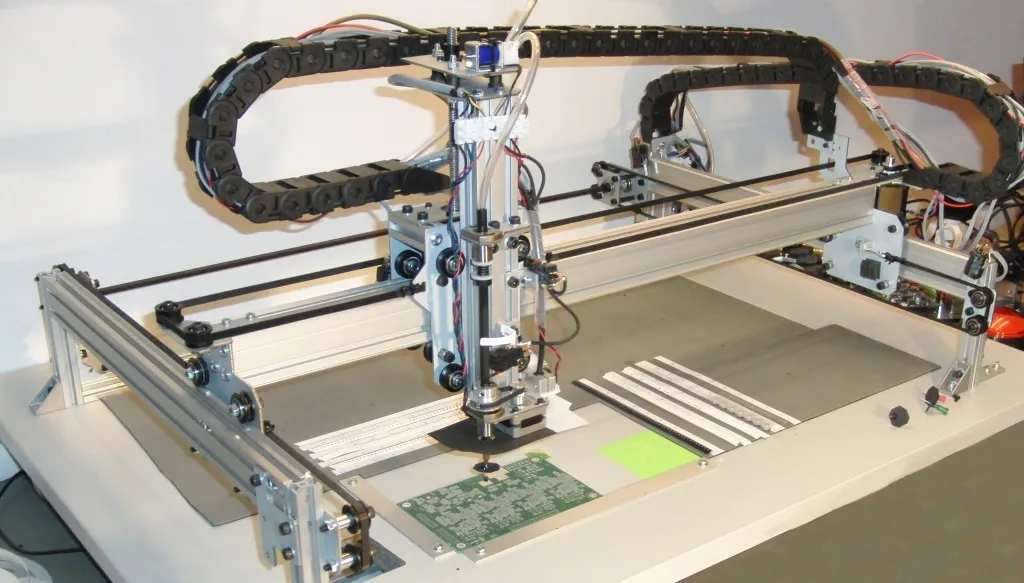

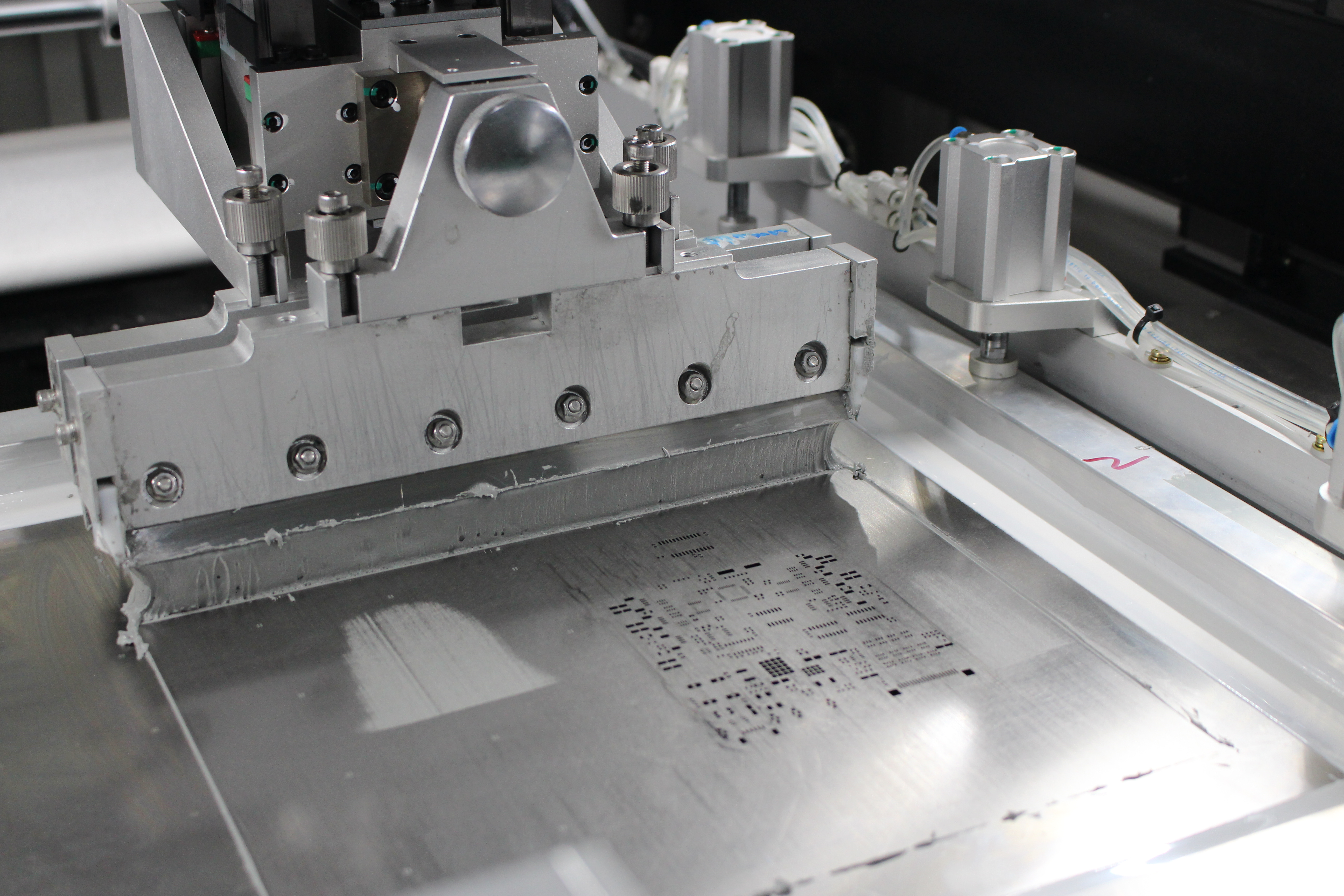

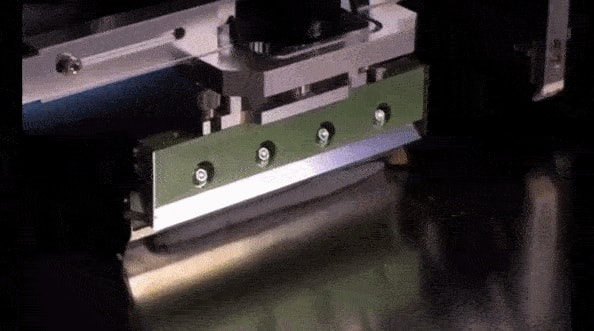

Solder paste printing operates on a balance of material properties, equipment settings, and environmental factors. The stencil, typically made of stainless steel, contains apertures corresponding to the board's pad layout. Solder paste is forced through these apertures onto the board using a squeegee, which moves across the stencil at a controlled speed and pressure. The paste must fill the apertures completely without excess residue on the stencil surface to prevent defects. Key parameters include stencil thickness, aperture design, and paste rheology, which dictates flow behavior under stress. Squeegee pressure plays a central role by ensuring uniform paste deposition. Too much pressure can cause paste to smear or damage the stencil, while insufficient pressure may leave incomplete deposits. Engineers must also consider the separation speed between the stencil and board after printing to avoid paste sticking or distortion. These principles underpin the consistency required for high quality assembly outcomes.

Related Reading: Optimizing Solder Paste Application with Step Up Stencils

Squeegee Pressure in Solder Paste Printing

Squeegee pressure is a critical parameter in achieving uniform solder paste deposition during printing. It refers to the force applied by the squeegee blade as it pushes paste across the stencil and into the apertures. Optimal pressure ensures a clean wipe of the stencil surface, preventing excess paste buildup that can lead to defects like bridging or insufficient solder volume. According to industry guidelines, such as those outlined in IPC-7527, pressure should be adjusted based on stencil size and paste type to maintain consistency. Excessive pressure risks damaging the stencil or causing paste to seep under the edges, while low pressure may fail to fill apertures fully. Engineers often start with a baseline setting and fine tune it during process validation, monitoring outcomes through solder paste inspection systems to confirm uniformity and volume accuracy.

Factors Influencing Squeegee Pressure

Several factors determine the appropriate squeegee pressure for a given solder paste printing setup. Stencil thickness and aperture size affect how much force is needed to push paste through openings. Thicker stencils or smaller apertures often require higher pressure to ensure complete filling. The type of squeegee blade, whether metal or polyurethane, also impacts pressure needs due to differences in flexibility and contact angle. Paste viscosity plays a role as well, with higher viscosity pastes demanding greater force for proper flow. Environmental conditions, such as temperature and humidity, can alter paste behavior, necessitating pressure adjustments to maintain consistency. Engineers must account for these variables during setup and continuously monitor process outputs to adapt pressure settings as needed for optimal results.

Techniques for Effective Solder Paste Printing

Achieving high quality solder paste printing requires a combination of well defined techniques and attention to process details. Engineers can implement the following practices to enhance outcomes and minimize defects in surface mount assembly.

- Stencil Design Optimization: Ensure aperture designs align with pad sizes on the board, following guidelines from standards like IPC-7527. Smaller apertures may need area ratio adjustments to improve paste release.

- Paste Selection and Storage: Choose solder paste with appropriate particle size and flux composition for the application. Store paste at recommended temperatures to maintain viscosity and prevent drying out.

- Printer Calibration: Regularly calibrate the printing equipment to maintain alignment between stencil and board. Verify squeegee speed and pressure settings to match process requirements.

- Inspection and Feedback: Utilize solder paste inspection systems post printing to measure deposit volume and height. Adjust parameters based on feedback to correct deviations promptly.

- Environmental Control: Maintain stable temperature and humidity in the printing area to prevent paste degradation or changes in flow behavior during application.

These techniques, when applied consistently, contribute to repeatable and reliable solder paste printing results in high volume production environments.

Best Practices for Managing Squeegee Pressure

Managing squeegee pressure effectively is central to successful solder paste printing. Engineers should begin by establishing a baseline pressure setting based on stencil specifications and paste characteristics, as recommended by standards such as IPC-7527. Incremental adjustments during trial runs help identify the optimal force that achieves a clean stencil wipe without excess paste residue. Monitoring the pressure per linear inch of the printable area ensures even distribution across the stencil surface. Regular maintenance of squeegee blades is necessary to prevent wear or deformation that could alter contact dynamics and affect pressure consistency. Additionally, pairing pressure adjustments with controlled separation speed between stencil and board after printing aids in clean paste release from apertures. By integrating these practices, engineers can mitigate common issues like incomplete deposits or smearing, ensuring high quality solder joints.

Related Reading: Mastering Squeegee Choices for Flawless Solder Paste Application in PCB Assembly

Troubleshooting Common Solder Paste Printing Issues

Even with optimized settings, solder paste printing can encounter challenges that impact assembly quality. Engineers often face issues like insufficient paste volume, where deposits fail to cover pads adequately, often due to low squeegee pressure or clogged apertures. Increasing pressure or cleaning the stencil can resolve this problem. Bridging, where paste connects adjacent pads, may result from excessive pressure or poor stencil design, requiring pressure reduction or aperture adjustments. Paste smearing on the stencil surface indicates overpressure or improper squeegee angle, necessitating recalibration of printer settings. Inconsistent deposits can stem from uneven pressure distribution or paste drying out, highlighting the need for environmental control and regular paste kneading. Addressing these issues promptly through systematic analysis and adjustment ensures process stability and minimizes production downtime.

Conclusion

Solder paste printing remains a pivotal process in surface mount technology assembly, directly affecting the quality and reliability of electronic products. Mastering squeegee pressure and employing effective techniques are essential for electrical engineers aiming to achieve consistent results and minimize defects. By understanding the technical principles, optimizing pressure settings, and adhering to best practices, professionals can enhance process control and ensure robust solder joints. Standards like IPC-7527 provide valuable guidance for refining solder paste printing approaches in modern manufacturing. As electronic designs grow more complex, continuous learning and adaptation of these methods will remain critical to meeting industry demands and maintaining high production standards.

FAQs

Q1: What factors affect squeegee pressure in solder paste printing?

A1: Squeegee pressure in solder paste printing is influenced by stencil thickness, aperture size, paste viscosity, and squeegee blade material. Environmental conditions like temperature and humidity also play a role. Engineers must adjust pressure to ensure uniform paste deposition, following guidelines from standards like IPC-7527, while monitoring outcomes through inspection systems to maintain consistency.

Q2: How can solder paste printing techniques reduce defects?

A2: Effective solder paste printing techniques, such as optimizing stencil design, calibrating printer settings, and controlling environmental factors, minimize defects like bridging or insufficient volume. Regular inspection and feedback loops allow for quick adjustments. Adhering to industry standards ensures repeatable results, enhancing overall assembly quality for reliable solder joints.

Q3: Why is squeegee pressure critical for solder paste printing quality?

A3: Squeegee pressure determines how evenly solder paste fills stencil apertures and deposits onto the board. Incorrect pressure can cause smearing or incomplete deposits, leading to assembly defects. Proper adjustment, aligned with process parameters and standards, ensures a clean stencil wipe and consistent paste application for high quality results.

Q4: What are common issues in solder paste printing and their solutions?

A4: Common solder paste printing issues include insufficient paste volume, bridging, and smearing. Low pressure or clogged apertures often cause insufficient volume, resolved by pressure increase or stencil cleaning. Bridging results from excess pressure, requiring reduction. Smearing indicates overpressure, needing printer recalibration for optimal performance.

References

IPC-7527 — Requirements for Solder Paste Printing. IPC, 2012.

IPC-A-610H — Acceptability of Electronic Assemblies. IPC, 2020.

IPC J-STD-005A — Requirements for Soldering Pastes. IPC, 2012.