What Are Blind Vias and Why Are They Essential for Signal Integrity?

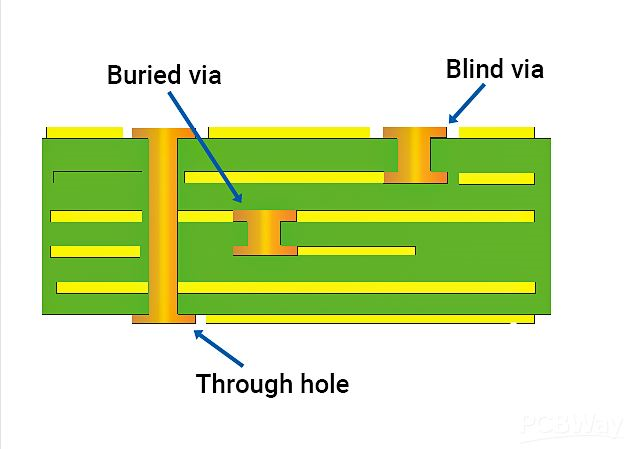

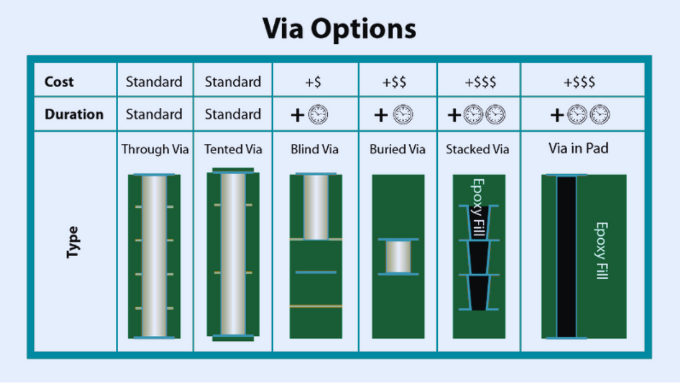

Blind vias represent a specialized type of vertical interconnect in multilayer printed circuit boards (PCBs). Unlike traditional through-hole vias that penetrate all layers, blind vias connect an outer layer to only one or more internal layers, without extending all the way through the board. This characteristic makes them particularly valuable in high-density interconnect (HDI) designs where maximizing board space is crucial.

The primary advantage of blind vias, particularly concerning signal integrity, stems from their ability to shorten signal path lengths. In high-speed circuits, extended signal routes can introduce unwanted delays, signal degradation, and distortion. By allowing signals to traverse shorter distances between layers, blind vias effectively minimize parasitic capacitance and inductance, which helps preserve signal clarity and reduces interference, especially in applications like 5G communication boards operating at gigahertz frequencies.

Related Reading: Unlocking PCB Density: A Beginner's Guide to Blind Vias

Key Considerations for Blind Via Pad Design

The design of the pad for a blind via is fundamental to ensuring robust electrical connections and maintaining signal quality throughout the PCB. The pad is the conductive area where the via terminates, connecting to traces or components. Inadequate pad design can lead to signal reflections or mechanical stress during the manufacturing process.

Pad Dimensions and Form

The dimensions of the blind via pad must be precisely calculated, taking into account the via's drill diameter and the specific manufacturing processes involved. A general guideline suggests the pad diameter should be at least 1.5 times the drill diameter to facilitate proper plating and ensure a reliable connection. For instance, a 0.2 mm drill might require a 0.3 mm pad. A circular pad shape is commonly preferred due to its ability to distribute stress uniformly during drilling and plating operations.

Understanding Aspect Ratio

The aspect ratio, defined as the ratio of the via's depth to its diameter, is another critical design parameter. For blind vias, a lower aspect ratio (ideally less than 1:1) is desirable. This ensures uniform copper deposition during plating, which is vital for electrical reliability and preventing signal loss. High aspect ratios can result in uneven plating, leading to impedance mismatches that negatively impact signal integrity.

Strategic Placement and Routing

Strategic placement of blind via pads is essential to prevent interference with adjacent traces or components. In high-speed applications, position the via as close as possible to its signal source or destination. This minimizes "stub effects"—unused portions of the via that can act as antennas, causing signal reflections. Furthermore, routing signals through blind vias in a controlled manner helps maintain consistent impedance, often targeting a 50-ohm characteristic impedance for high-frequency circuits.

What Is an Anti-Pad and How Does It Influence Signal Integrity?

An anti-pad, also known as a clearance pad, is a non-conductive area or void intentionally created around a via on an internal plane layer of a PCB. Its fundamental purpose is to isolate the via from unintended electrical contact with the surrounding conductive plane (such as a ground or power plane) while precisely controlling the via structure's impedance. In high-speed designs, anti-pads are indispensable for preserving signal integrity.

Without an anti-pad, a via passing through a power or ground plane could inadvertently create a short circuit or introduce excessive parasitic capacitance. This would severely disrupt signal transmission. By carefully dimensioning the anti-pad, engineers can fine-tune the via's impedance to match the impedance of the connecting traces, thereby minimizing signal reflections and ensuring clean, uninterrupted signal flow. For example, in a system designed for a 50-ohm impedance, the anti-pad size can be adjusted to maintain this value precisely.

Best Practices for Blind Via Anti-Pad Design

Optimizing the design of blind via anti-pads is crucial for maximizing signal performance in multilayer PCBs. Adhering to specific best practices can significantly enhance overall circuit reliability.

Determining Optimal Anti-Pad Size

The correct anti-pad size is contingent on several factors, including the via diameter, the PCB layer stack-up, and the target impedance. A common guideline suggests an anti-pad diameter that is 2 to 3 times the via drill diameter. For a 0.2 mm via, an anti-pad between 0.4 mm and 0.6 mm might be appropriate. However, for critical high-speed designs (e.g., lines operating at 10 GHz), electromagnetic simulation tools provide the most accurate values by modeling the complex interaction between the via and the plane.

Customizing for Specific Layers

In complex multilayer PCBs, different internal planes may require varying anti-pad sizes based on their specific function (e.g., dedicated ground planes versus power planes). For blind vias that only traverse a limited number of layers, it is important to apply anti-pads exclusively to the relevant planes. This prevents introducing unnecessary capacitance or inductance on layers where isolation is not required or where the via does not make contact.

Mitigating Capacitive Coupling

Excessive capacitive coupling between a via and its surrounding plane can significantly degrade signal integrity, particularly by slowing down signal rise times in circuits operating above 1 GHz. A properly designed anti-pad increases the physical separation between the via barrel and the plane, thereby reducing this unwanted coupling. Utilizing PCB design software for simulation allows engineers to adjust anti-pad dimensions to minimize coupling effects and optimize signal performance.

General PCB Design Guidelines for Vias and Signal Integrity

Beyond the specific considerations for blind via pads and anti-pads, a broader set of best practices for via design is crucial for enhancing signal integrity. These guidelines are applicable to all via types and are particularly vital in high-speed and HDI applications.

Implementing Controlled Impedance Routing

Maintaining consistent impedance across the entire signal path, including through vias, is paramount for high-speed signals. Even small impedance mismatches, as little as 5 ohms, can cause significant signal reflections. Employing simulation tools to match the impedance of traces, vias, and pads—adjusting anti-pad sizes and via dimensions as necessary—is a key practice.

Optimizing Via Placement

Vias should be positioned carefully, away from sensitive analog components or high-speed digital traces, to prevent crosstalk. If multiple vias are required, staggering their placement can help reduce electromagnetic interference (EMI). In HDI designs, blind vias inherently save space, allowing for tighter component placement without compromising signal quality.

Related Reading: Blind Vias in PCB Design: Optimizing High-Density Boards

Incorporating Robust Ground Planes

A continuous, solid ground plane situated near signal layers provides an essential low-impedance return path for high-frequency signals, thereby minimizing noise and EMI. It is crucial to ensure that blind vias have nearby ground vias to maintain this return path, particularly in designs operating above 500 MHz.

Minimizing Via Stubs

Via stubs, which are unused portions of a via, can act as resonant structures that distort high-speed signals. While blind vias inherently mitigate this issue by not extending through the entire board, precise design of the via depth is still important to avoid any unnecessary length that could behave as a stub.

Comprehensive Simulation and Testing

Prior to finalizing a PCB layout, it is imperative to use simulation software to model signal behavior through blind vias and anti-pads. These tools can predict potential issues such as signal reflection, crosstalk, and impedance mismatches, enabling early design adjustments. Post-manufacturing, using a time-domain reflectometer (TDR) to verify impedance values, typically targeting a ±10% tolerance for critical signals, confirms design integrity.

Overcoming Challenges in Blind Via and Anti-Pad Design

Designing blind vias and anti-pads for optimal signal integrity presents several challenges, particularly in the context of complex multilayer boards. Awareness of these common issues and their solutions is crucial.

Addressing Manufacturing Limitations

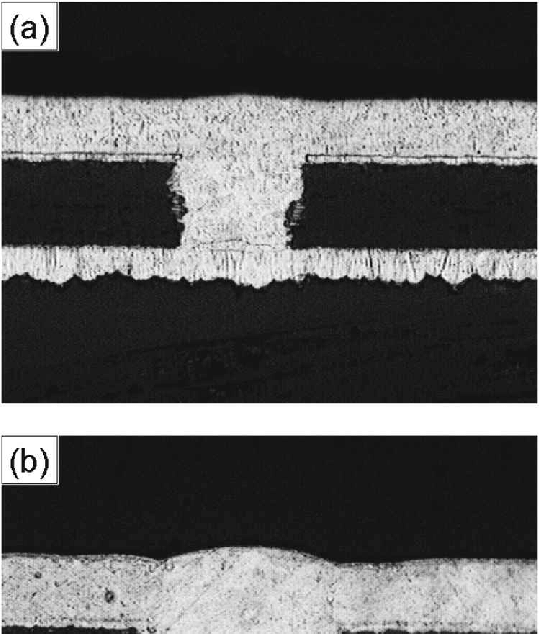

Blind vias demand highly precise drilling and plating processes, often utilizing laser technology for microvias in HDI boards. If the aspect ratio is too high, plating failures can occur, leading to open circuits.

Solution: Collaborate closely with your PCB manufacturer to understand their specific capabilities and design within those limits, generally keeping aspect ratios below 1:1.

Mitigating Impedance Mismatches

Even minor deviations in anti-pad size or via dimensions can lead to impedance mismatches, resulting in detrimental signal reflections.

Solution: Employ simulation tools to precisely fine-tune anti-pad and pad dimensions, ensuring a consistent target impedance (e.g., 50 ohms) throughout the entire signal path.

Managing Signal Crosstalk

In densely packed layouts, signals passing through adjacent vias can interfere with one another, degrading overall performance.

Solution: Ensure adequate spacing between vias and strategically incorporate ground vias to shield high-speed signals. A general guideline is to maintain a separation of at least three times the via diameter between critical signals.

Concluding Thoughts: Optimizing PCB Performance with Intelligent Via Design

Mastering the design of blind via pads and anti-pads is indispensable for achieving high signal integrity in modern PCB layouts, especially for high-speed and high-density electronic applications. By meticulously considering pad sizes, anti-pad dimensions, impedance control, and strategic via placement, engineers can effectively minimize signal loss, reduce electromagnetic noise, and ensure robust, reliable performance. Adhering to comprehensive PCB design best practices for vias, from controlled impedance routing to thorough simulation and post-manufacturing testing, further elevates the quality of the final product.

At AIVON, we recognize the critical importance of precision in both PCB design and fabrication. By applying the principles detailed in this guide, designers can create circuits that meet the demanding requirements of contemporary electronic systems, whether for telecommunications, computing, or consumer devices. With a well-informed approach, blind vias and anti-pads transform into powerful tools for maintaining signal integrity and optimizing overall board performance