Introduction

Signal integrity is a cornerstone of modern PCB design, especially for high-speed electronic systems. As devices operate at faster frequencies, maintaining the quality of electrical signals becomes critical to prevent data loss and ensure system reliability. For electrical engineers, understanding signal integrity involves mastering concepts like impedance, signal reflections, dielectric constant (Dk), dissipation factor (Df), and the use of materials such as High-Tg FR4. Additionally, designing differential pairs correctly plays a vital role in minimizing noise and crosstalk. This article explores the principles of signal integrity, the challenges posed by high-speed signals, and practical strategies to optimize PCB layouts. By addressing these factors, designers can create robust boards for applications ranging from telecommunications to automotive electronics.

What Is Signal Integrity and Why It Matters

Signal integrity refers to the preservation of an electrical signal's quality as it travels through a printed circuit board. In high-speed designs, signals are prone to distortion due to factors like impedance mismatches, signal reflections, and material properties. Poor signal integrity can lead to errors in data transmission, timing issues, and electromagnetic interference, ultimately affecting system performance. For electrical engineers working on complex systems, ensuring signal integrity is not just a design requirement but a necessity for meeting industry standards and customer expectations. As frequencies increase in applications like 5G and IoT, the importance of controlling parameters such as Dk, Df, and trace geometry becomes even more pronounced. Without proper attention, even minor design flaws can result in significant operational failures.

Technical Principles of Signal Integrity

Impedance and Its Role

Impedance is the measure of opposition to the flow of alternating current in a circuit. In PCB design, maintaining consistent impedance across transmission lines is essential to prevent signal degradation. Mismatches in impedance can cause reflections, where part of the signal bounces back toward the source, leading to noise and potential data errors. Engineers must calculate the characteristic impedance of traces based on their width, thickness, and the dielectric properties of the substrate. Standards such as IPC-2141A provide guidelines for designing controlled impedance traces to ensure signal integrity in high-speed applications.

Related Reading: Designing for Signal Integrity: Mastering 50 Ohm PCB Impedance Control

Signal Reflections and Their Impact

Signal reflections occur when there is a sudden change in impedance along a transmission line. This can happen at connectors, vias, or terminations if not properly matched. Reflections distort the original signal, causing overshoot, undershoot, or ringing, which can interfere with data integrity. To mitigate this, engineers use termination techniques like series or parallel resistors to match impedance at critical points. Understanding the behavior of reflections is crucial for layouts involving high-speed signals, as even small discontinuities can amplify issues at higher frequencies.

Dielectric Constant (Dk) and Dissipation Factor (Df)

The dielectric constant (Dk) represents a material's ability to store electrical energy in an electric field, influencing the speed at which signals propagate through a PCB substrate. A lower Dk value results in faster signal transmission, which is beneficial for high-speed designs. The dissipation factor (Df) measures the energy loss in the material as heat during signal transmission. High Df values can lead to signal attenuation, especially at higher frequencies. Selecting materials with appropriate Dk and Df values is vital for maintaining signal integrity, particularly in applications requiring minimal loss.

High-Tg FR4 Materials in High-Speed Designs

High-Tg FR4 materials are a variant of the standard glass-reinforced epoxy laminate, designed to withstand higher temperatures without deforming. The term Tg refers to the glass transition temperature, above which the material loses its rigidity. High-Tg FR4 offers improved thermal stability, making it suitable for environments with elevated operating temperatures or during high-power operations. While standard FR4 may suffice for low-speed designs, High-Tg variants are preferred for high-speed applications due to their better mechanical and electrical performance under stress. Engineers must balance cost and performance when choosing these materials for specific projects.

Differential Pairs and Noise Reduction

Differential pairs are two closely spaced traces that carry equal and opposite signals. This configuration is widely used in high-speed designs to reduce electromagnetic interference and crosstalk. By maintaining tight coupling between the traces, differential pairs cancel out common-mode noise, ensuring cleaner signal transmission. Proper spacing, length matching, and impedance control are critical when designing differential pairs to avoid skew and maintain signal integrity. Standards like IPC-2221B offer detailed recommendations for routing differential pairs to achieve optimal performance in high-speed circuits.

Related Reading: Mastering Differential Pair Routing for High-Speed PCB Design

Practical Solutions for Signal Integrity in PCB Design

Controlled Impedance Design

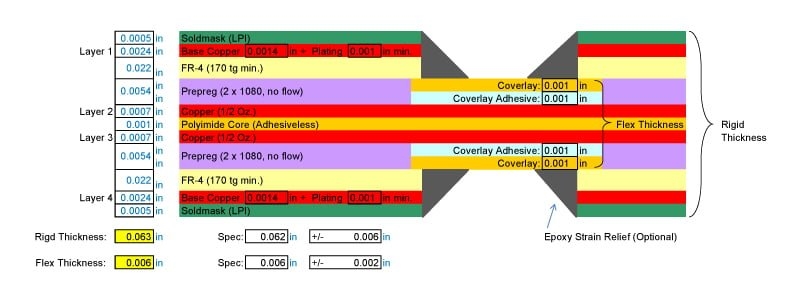

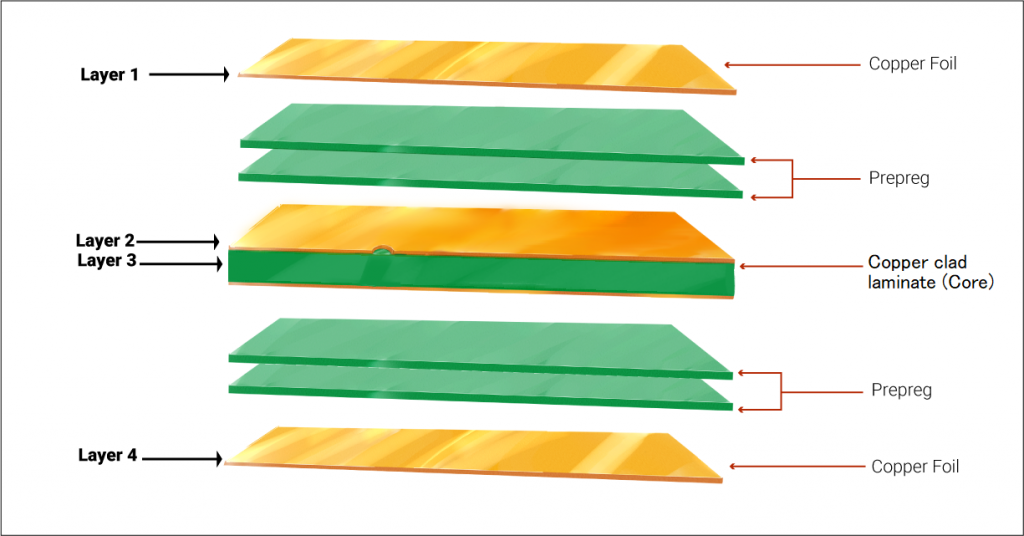

To achieve consistent impedance, designers must carefully define trace widths and spacing based on the substrate's dielectric properties. Simulation tools aligned with industry standards can predict impedance values before fabrication, allowing adjustments during the design phase. Additionally, maintaining uniform layer stack-ups and minimizing vias in high-speed signal paths helps avoid impedance discontinuities. Referencing guidelines from IPC-2141A ensures that impedance calculations meet accepted norms for high-speed performance.

Minimizing Signal Reflections

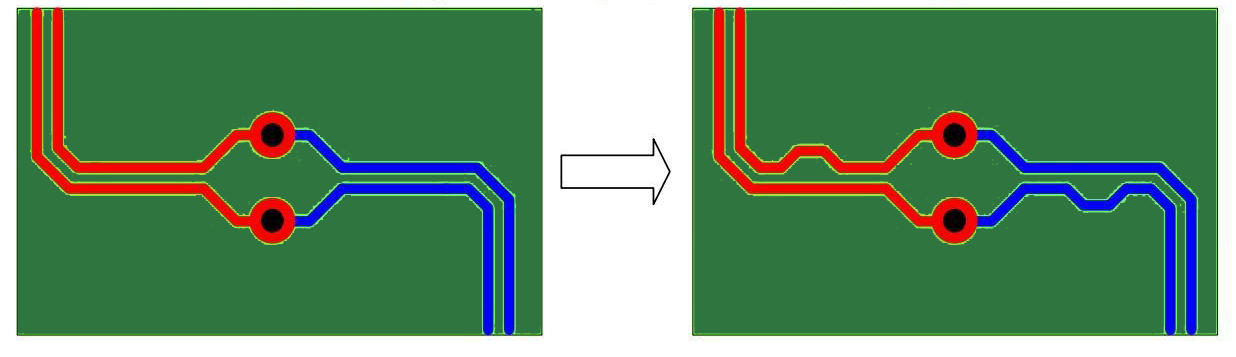

Reducing signal reflections involves proper termination strategies and avoiding abrupt changes in trace geometry. Series termination places a resistor near the signal source to match the trace impedance, while parallel termination uses a resistor at the load end. Careful routing to avoid sharp bends and ensuring consistent trace lengths in differential pairs also mitigates reflection issues. Engineers should prioritize smooth transitions at connectors and vias to maintain signal quality.

Material Selection for Dk and Df Optimization

Choosing a substrate with suitable Dk and Df values is critical for high-speed designs. Materials with lower Dk enable faster signal propagation, while lower Df reduces energy loss. High-Tg FR4 materials often strike a balance between cost and performance for many applications, though advanced laminates may be necessary for ultra-high-frequency designs. Consulting material datasheets and adhering to standards like IPC-4101E helps in selecting substrates that align with signal integrity requirements.

Best Practices for Differential Pair Routing

When routing differential pairs, engineers must ensure equal trace lengths to prevent timing skew. Maintaining consistent spacing between the pair minimizes crosstalk, while avoiding routing over splits in the ground plane preserves signal integrity. Using reference planes beneath differential pairs provides a stable return path for signals. Following layout guidelines from IPC-2221B ensures that these pairs perform reliably in high-speed environments.

Grounding and Power Plane Design

A solid grounding strategy is fundamental to signal integrity. Continuous ground planes beneath signal layers reduce loop inductance and provide a low-impedance return path. Separating analog and digital grounds can prevent noise coupling in mixed-signal designs. Power planes should be designed to minimize voltage drops and include decoupling capacitors near high-speed components to filter noise. These practices collectively enhance the overall performance of the PCB.

Troubleshooting Signal Integrity Issues

In real-world scenarios, signal integrity issues often manifest as data errors or unexpected system behavior. Engineers can use time-domain reflectometry to identify impedance mismatches and locate reflection points along a trace. Analyzing eye diagrams helps assess signal quality by revealing jitter, noise, and timing issues. If problems arise from material properties, switching to a substrate with better Dk and Df characteristics may resolve attenuation concerns. For differential pairs, rechecking length matching and spacing often uncovers root causes of skew or crosstalk. A systematic approach, guided by standards like IPC-A-600K for board acceptability, ensures that troubleshooting efforts lead to effective solutions.

Conclusion

Signal integrity remains a critical focus for PCB designers working on high-speed applications. By understanding and controlling factors like impedance, signal reflections, dielectric constant (Dk), dissipation factor (Df), and material choices such as High-Tg FR4, engineers can build reliable and efficient designs. Implementing best practices for differential pairs and grounding further enhances performance, reducing noise and crosstalk. As electronic systems continue to push frequency boundaries, adhering to established industry standards and leveraging precise design techniques will be essential for success. Through careful planning and attention to detail, PCB designers can ensure optimal signal integrity across diverse applications.

FAQs

Q1: How does impedance affect signal integrity in PCB design?

A1: Impedance directly influences how signals travel through a PCB. Mismatches in impedance lead to signal reflections, causing noise and data errors. Designing traces with controlled impedance, following standards like IPC-2141A, ensures consistent signal quality. Proper trace width and dielectric selection are key to maintaining impedance in high-speed layouts.

Q2: What role do Dk and Df play in high-speed PCB performance?

A2: Dielectric constant (Dk) affects signal propagation speed, with lower values enabling faster transmission. Dissipation factor (Df) indicates energy loss as heat, impacting signal strength. Choosing materials with optimal Dk and Df values is crucial for minimizing attenuation and ensuring reliable performance in high-speed designs.

Q3: Why are High-Tg FR4 materials preferred for demanding applications?

A3: High-Tg FR4 materials offer superior thermal stability, resisting deformation at elevated temperatures. This makes them ideal for high-speed or high-power designs where heat dissipation is a concern. Their enhanced mechanical properties also support reliability in harsh environments, balancing cost and performance effectively.

Q4: How can differential pairs improve signal integrity in PCB layouts?

A4: Differential pairs reduce noise and crosstalk by carrying equal and opposite signals. Tight coupling and length matching prevent timing skew, while proper spacing minimizes interference. Following routing guidelines from standards like IPC-2221B ensures that differential pairs maintain signal integrity in high-speed applications.

References

IPC-2141A — Design Guide for High-Speed Controlled Impedance Circuit Boards. IPC, 2004.

IPC-2221B — Generic Standard on Printed Board Design. IPC, 2012.

IPC-4101E — Specification for Base Materials for Rigid and Multilayer Printed Boards. IPC, 2017.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.