Introduction

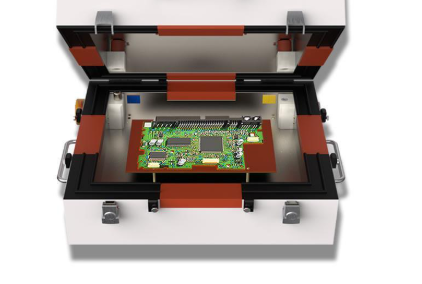

In the rapidly evolving field of LED lighting, the demand for high performance drives innovation in every component, including printed circuit boards (PCBs). Traditional FR-4 materials, while cost effective, often fall short in meeting the thermal and electrical requirements of modern high power LED systems. Advanced PCB materials such as high Tg laminates, ceramic filled substrates, thermally conductive laminates, Rogers PCB, and PTFE PCB offer superior properties tailored for these applications. These materials ensure better heat dissipation, improved reliability, and enhanced electrical performance under demanding conditions. This article explores the limitations of standard FR-4 and delves into the benefits and applications of advanced PCB material properties. Electrical engineers will find detailed insights into selecting the right materials to optimize LED PCB cost and performance for cutting edge lighting solutions.

Why Advanced PCB Materials Matter for LED Lighting

LED lighting systems, especially high power setups, generate significant heat during operation. Efficient thermal management is critical to maintain LED lifespan and performance. Standard FR-4 materials, composed of woven fiberglass and epoxy resin, have limited thermal conductivity, often leading to hotspots and potential failure in high intensity applications. Beyond thermal concerns, modern LED designs require materials with excellent dielectric properties to support high frequency signals and minimize signal loss. Advanced PCB materials address these challenges by offering higher thermal conductivity, better dimensional stability, and improved electrical insulation. For electrical engineers, selecting the right material directly impacts system reliability and efficiency. With the growing adoption of smart lighting and compact designs, understanding PCB material properties becomes essential to meet stringent performance criteria in LED applications.

Technical Principles of Advanced PCB Materials

High Tg PCB Materials

High Tg PCB materials refer to laminates with a glass transition temperature (Tg) above 170 degrees Celsius. This property indicates the temperature at which the material transitions from a rigid to a rubbery state. A higher Tg ensures better thermal stability, making these materials suitable for environments with elevated temperatures. In LED lighting, where heat dissipation is a constant concern, high Tg materials prevent deformation and maintain structural integrity during operation. They also exhibit lower coefficients of thermal expansion, reducing the risk of delamination or cracking under thermal stress.

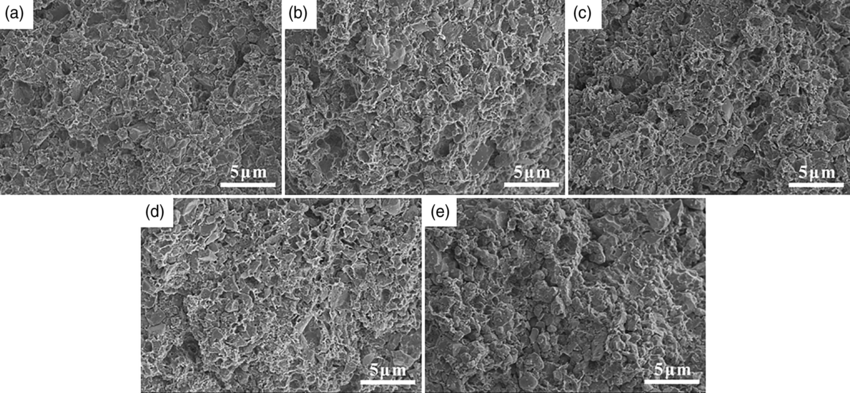

Ceramic Filled PCB

Ceramic filled PCB substrates incorporate ceramic particles into the laminate matrix to enhance thermal conductivity and mechanical strength. These materials excel in dissipating heat away from LED components, ensuring uniform temperature distribution across the board. Additionally, ceramic filled laminates offer excellent dielectric strength, making them ideal for high voltage LED applications. Their rigidity also minimizes warpage, a common issue in high temperature environments, thus improving long term reliability.

Thermally Conductive Laminates

Thermally conductive laminates are engineered to transfer heat efficiently from heat generating components to heat sinks or the ambient environment. These materials typically feature a high thermal conductivity value, often several times greater than standard FR-4. In LED lighting, thermally conductive laminates prevent thermal buildup, protecting sensitive components from degradation. They are particularly useful in compact designs where space for additional cooling mechanisms is limited.

Rogers PCB and PTFE PCB for High Frequency Needs

Rogers PCB and PTFE PCB materials are designed for applications requiring superior high frequency performance. Rogers materials, known for their low dielectric loss, provide stable electrical properties across a wide range of frequencies. PTFE, or polytetrafluoroethylene, offers exceptional chemical resistance and low dielectric constant, minimizing signal loss in high speed circuits. While not primarily used for thermal management, these materials are critical in smart LED systems that integrate control circuits operating at high frequencies. Their use ensures signal integrity in advanced lighting designs.

Practical Solutions for Selecting PCB Materials in LED Applications

Assessing Thermal Requirements

When designing the LED lighting PCB, the first step is to evaluate the thermal load of the system. High power LEDs can generate substantial heat, necessitating materials with high thermal conductivity. Thermally conductive laminates or ceramic filled PCB substrates are often the best choice for such applications. Engineers should refer to standardized testing methods, such as those outlined in IPC-TM-650, to compare the thermal performance of different materials under simulated operating conditions.

Balancing Electrical Performance

For LED systems incorporating smart controls or wireless communication, electrical performance becomes a priority. Materials like PTFE PCB or Rogers PCB ensure minimal signal loss and maintain dielectric stability at high frequencies. Selecting materials with a low dielectric constant and loss tangent is crucial for these designs. Testing per IPC-6012E standards can validate the electrical reliability of chosen substrates in high frequency environments.

Considering LED PCB Cost

While advanced materials offer superior performance, LED PCB cost remains a significant factor in material selection. High Tg PCB materials and thermally conductive laminates often strike a balance between enhanced properties and affordability. Ceramic filled PCB substrates, while highly effective for thermal management, can increase production costs due to specialized manufacturing processes. Engineers must weigh performance benefits against budget constraints, ensuring cost effective solutions without compromising reliability.

Ensuring Compliance with Industry Standards

Adhering to recognized industry standards is essential for quality and performance assurance. Specifications such as IPC-A-600K provide guidelines for the acceptability of printed boards, covering aspects like material integrity and dimensional tolerances. Compliance with these standards ensures that selected materials meet the rigorous demands of LED lighting applications, reducing the risk of field failures.

Material Properties and Their Impact on LED Performance

Understanding PCB material properties is fundamental to optimizing LED lighting designs. The list below summarizes key characteristics of advanced materials compared to standard FR-4, providing a quick reference for engineers.

- Standard FR-4: Thermal Conductivity 0.3 to 0.5 W/mK; Dielectric Constant 4.5 to 4.8; Tg 130 to 140°C; Typical Application: Low power LED strips.

- High Tg PCB Materials: Thermal Conductivity 0.5 to 0.8 W/mK; Dielectric Constant 4.0 to 4.5; Tg 170 to 200°C; Typical Application: Medium to high power LED modules.

- Ceramic Filled PCB: Thermal Conductivity 1.0 to 3.0 W/mK; Dielectric Constant 5.0 to 6.0; Tg 180 to 220°C; Typical Application: High power LED arrays.

- Thermally Conductive Laminates: Thermal Conductivity 1.0 to 5.0 W/mK; Dielectric Constant 4.0 to 5.0; Tg 150 to 180°C; Typical Application: Compact high intensity LED designs.

- PTFE PCB: Thermal Conductivity 0.2 to 0.3 W/mK; Dielectric Constant 2.1 to 2.5; Tg: Not applicable; Typical Application: Smart LED systems with high frequency needs.

Troubleshooting Common Issues with Advanced Materials

When integrating advanced PCB materials into LED designs, engineers may encounter specific challenges. Ceramic filled PCB substrates, for instance, can be brittle, requiring careful handling during assembly to prevent cracking. Following guidelines from IPC-6012E during manufacturing helps mitigate such risks by ensuring proper material qualification. Another common issue is the higher LED PCB cost associated with specialized laminates. To address this, engineers can opt for hybrid designs, combining high performance materials in critical areas with cost effective options elsewhere. Additionally, verifying material compatibility with soldering processes per JEDEC J-STD-020E standards prevents issues like delamination during reflow, ensuring robust assembly outcomes.

Conclusion

Advanced PCB materials play a pivotal role in meeting the demanding requirements of high performance LED lighting. Moving beyond traditional FR-4, options like high Tg PCB materials, ceramic filled PCB, thermally conductive laminates, Rogers PCB, and PTFE PCB provide tailored solutions for thermal management, electrical performance, and reliability. By understanding PCB material properties and aligning material selection with application needs, electrical engineers can design LED systems that excel in efficiency and durability. Balancing LED PCB cost with performance benefits remains a key consideration, alongside adherence to industry standards for quality assurance. These materials pave the way for innovative lighting solutions in an ever advancing technological landscape.

FAQs

Q1: What are the benefits of using high Tg PCB materials in LED lighting?

A1: High Tg PCB materials offer superior thermal stability with glass transition temperatures above 170 degrees Celsius. They resist deformation under high heat, which is common in LED applications. This property ensures structural integrity, reduces thermal expansion, and prevents issues like delamination. For electrical engineers, these materials provide a reliable foundation for medium to high power LED designs, enhancing system lifespan and performance under demanding conditions.

Q2: How do ceramic filled PCB substrates improve thermal management?

A2: Ceramic filled PCB substrates incorporate ceramic particles to boost thermal conductivity, often reaching values between 1.0 and 3.0 W/mK. This allows efficient heat dissipation from LED components, preventing hotspots. Their high dielectric strength also suits high voltage setups. Engineers benefit from uniform temperature distribution, which extends LED lifespan and maintains performance, especially in high power lighting systems requiring robust thermal solutions.

Q3: Why consider thermally conductive laminates for compact LED designs?

A3: Thermally conductive laminates excel in transferring heat away from LED components, with conductivity values up to 5.0 W/mK. In compact designs, where space for cooling is limited, these materials prevent thermal buildup effectively. They protect sensitive parts from degradation, ensuring reliability. For electrical engineers, this makes them ideal for high intensity LED applications, balancing performance with spatial constraints in modern lighting solutions.

Q4: How does LED PCB cost influence material selection?

A4: LED PCB cost significantly impacts material choice in design projects. Advanced options like ceramic filled PCB substrates offer excellent thermal management but increase expenses due to complex manufacturing. High Tg PCB materials often provide a cost effective middle ground with good performance. Engineers must evaluate budget limits against performance needs, ensuring optimal material selection without compromising the reliability of LED lighting systems.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

IPC-TM-650 — Test Methods Manual. IPC, 2021.

JEDEC J-STD-020E — Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices. JEDEC, 2014.