Introduction

In the realm of printed circuit board design, material selection plays a pivotal role in determining performance under extreme conditions. While FR-4 has long been the standard for many applications, its limitations become apparent in high-temperature environments. This is where polyimide PCB materials shine, offering exceptional thermal stability and reliability. These substrates are engineered to withstand intense heat, making them ideal for industries like aerospace, where components face harsh operating conditions. This article explores the thermal advantages of polyimide PCBs, focusing on polyimide PCB thermal conductivity, polyimide PCB operating temperature, and polyimide PCB heat dissipation. Tailored for electric engineers, the discussion will cover technical principles, practical applications, and best practices for polyimide PCB thermal management, especially in demanding sectors such as aerospace.

What Are Polyimide PCBs and Why Do They Matter?

Polyimide PCBs are a class of circuit boards made from polyimide resin, a high-performance polymer known for its thermal and chemical resistance. Unlike traditional FR-4 materials, which are based on epoxy and glass fiber, polyimide substrates offer superior stability at elevated temperatures. This makes them a preferred choice for applications where thermal stress is a constant challenge. In industries like aerospace, where electronics must function reliably in extreme heat during flight or reentry phases, polyimide PCB aerospace applications are critical. Their ability to maintain structural integrity and electrical performance under such conditions sets them apart. Beyond temperature tolerance, polyimide materials also provide flexibility, allowing for use in both rigid and flexible circuit designs, expanding their utility in compact, high-density layouts.

Technical Principles of Polyimide PCB Thermal Performance

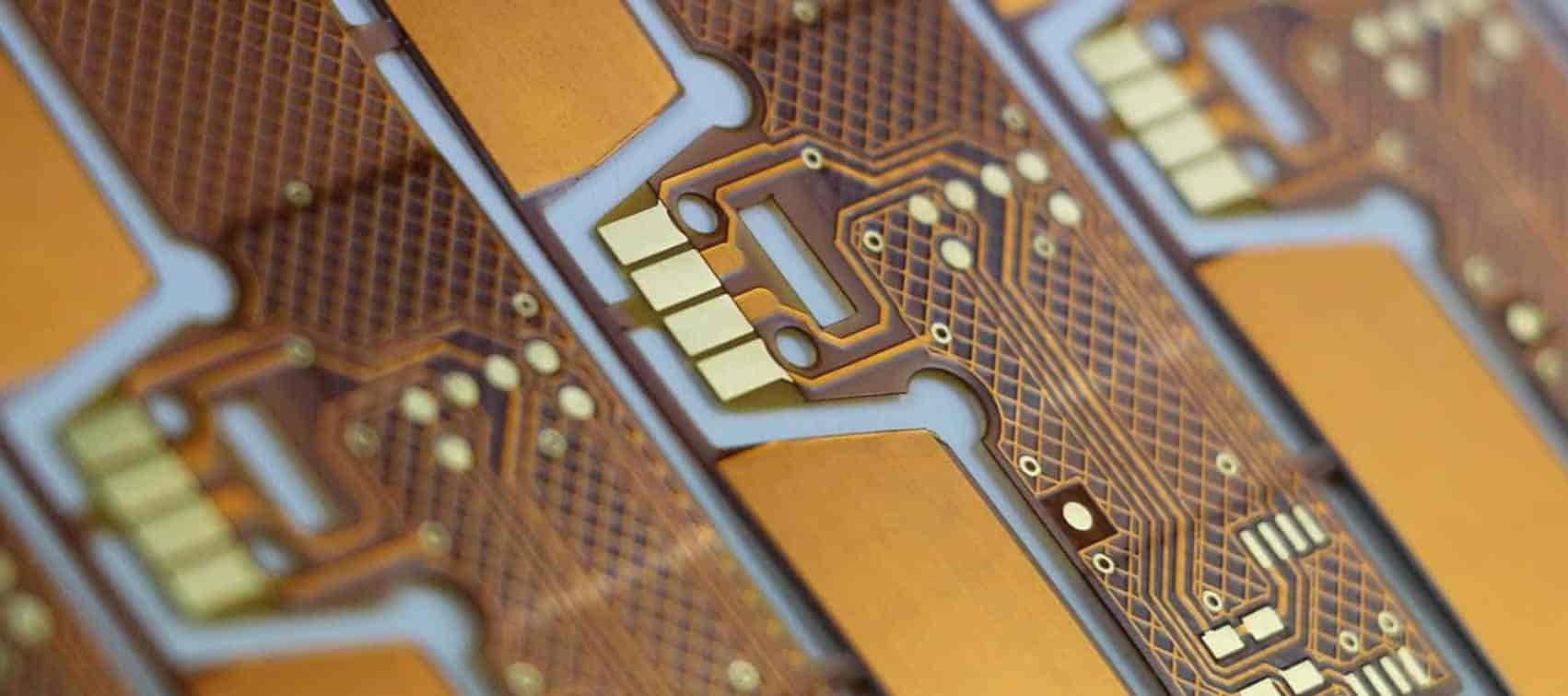

Understanding Polyimide PCB Thermal Conductivity

Thermal conductivity measures a material's ability to transfer heat. For polyimide PCBs, this property is crucial in determining how effectively heat is dissipated from components. While polyimide itself has relatively low thermal conductivity compared to metals, typically in the range specified by material standards, it is often combined with fillers or layered structures to enhance polyimide PCB heat dissipation. The focus in design is not just on raw conductivity but on how the material manages thermal gradients across the board. This ensures that heat is spread evenly, preventing hotspots that could damage sensitive components. Standards like IPC-6012E provide guidelines for evaluating thermal properties in high-performance PCBs, ensuring consistent behavior under stress.

Polyimide PCB Operating Temperature Range

One of the standout features of polyimide PCBs is their wide operating temperature range. These materials are designed to function reliably in environments far exceeding the limits of standard epoxy-based boards. According to industry standards such as IPC-A-600K, polyimide substrates are tested for performance in extreme conditions, ensuring they meet the demands of high-temperature applications. This capability is vital for polyimide PCB aerospace applications, where electronics must endure rapid temperature fluctuations. The ability to maintain dielectric strength and mechanical stability at such extremes prevents failures in critical systems, making polyimide a go-to material for mission-critical designs.

Mechanisms of Polyimide PCB Heat Dissipation

Effective polyimide PCB thermal management relies on the material’s inherent properties and design strategies. Polyimide’s resistance to thermal degradation allows it to withstand prolonged exposure to heat without breaking down. Additionally, its low coefficient of thermal expansion reduces the risk of warping or delamination during temperature cycles. When paired with proper layout techniques, such as strategic placement of thermal vias or heat sinks, polyimide PCB heat dissipation is optimized. These methods ensure that heat generated by components is efficiently transferred away, maintaining operational stability. Testing protocols outlined in IPC-6012E emphasize the importance of thermal stress testing to validate these mechanisms in real-world scenarios.

Practical Solutions for Polyimide PCB Thermal Management

Material Selection Criteria

Choosing the right polyimide material is the first step in achieving effective thermal management. Engineers must consider factors like glass transition temperature and thermal decomposition thresholds, as outlined in standards such as IPC-A-600K. These properties determine how the board will perform under heat stress. Additionally, understanding the specific requirements of the application, such as flexibility or rigidity, helps in selecting the appropriate polyimide variant. For polyimide PCB aerospace applications, where weight and durability are critical, lightweight yet robust formulations are prioritized.

Design Strategies for Enhanced Heat Dissipation

Beyond material choice, board layout plays a significant role in polyimide PCB thermal management. Incorporating thermal vias near high-power components allows heat to transfer to other layers or external sinks. Wider traces and larger copper areas can also improve heat spreading. Additionally, ensuring adequate spacing between heat-generating elements prevents localized overheating. Following design guidelines from IPC-6012E ensures that these strategies align with industry best practices, reducing the risk of thermal failures in high-temperature environments.

Assembly Considerations for High-Temperature Applications

During PCBA assembly, attention to soldering processes is essential for polyimide PCBs. These materials often require higher reflow temperatures due to their thermal stability, and standards like JEDEC J-STD-020E provide classifications for moisture sensitivity and reflow conditions. Proper handling prevents issues like delamination or void formation, which could compromise polyimide PCB heat dissipation. Using compatible adhesives and coatings that match the thermal properties of polyimide further enhances reliability, especially in demanding polyimide PCB aerospace applications.

Application Focus: Polyimide PCBs in Aerospace

In aerospace, electronics face unique challenges due to extreme temperatures, vibration, and pressure changes. Polyimide PCB aerospace applications are widespread, from avionics to satellite systems, where reliability is non-negotiable. The superior polyimide PCB operating temperature range allows these boards to function in environments where standard materials would fail. For instance, in spacecraft, components must endure the heat of reentry or the cold of space, and polyimide’s thermal stability ensures consistent performance. Moreover, its lightweight nature aligns with the industry’s focus on reducing payload mass without sacrificing durability.

Thermal management in aerospace also involves rigorous testing to simulate real-world conditions. Standards like IPC-6012E outline procedures for thermal cycling and shock testing, ensuring that polyimide PCBs can handle the stresses of flight. Engineers often integrate additional cooling mechanisms, such as forced air or liquid cooling, to complement the material’s inherent polyimide PCB thermal conductivity. These combined approaches guarantee that critical systems remain operational, even under the harshest conditions.

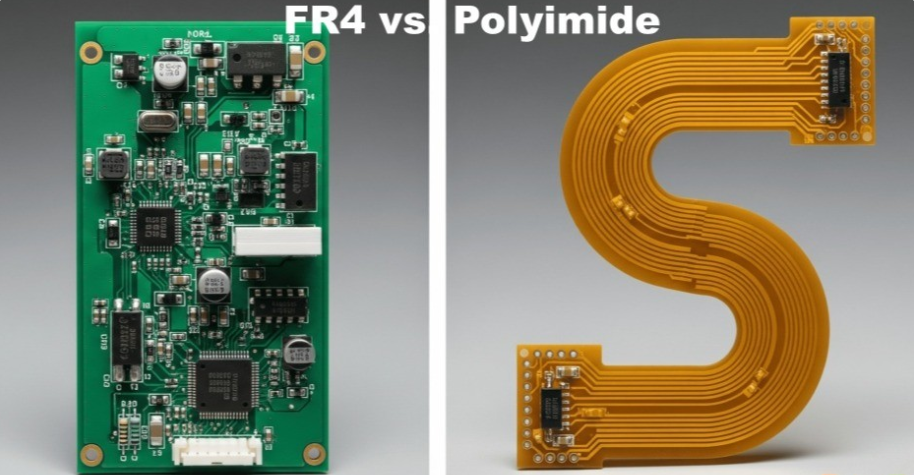

Comparing Polyimide PCBs to Traditional Materials

To understand the advantages of polyimide, a comparison with PCB FR4 is useful. FR-4 boards, while cost-effective and widely used, have limited thermal endurance, often failing in environments exceeding certain temperature thresholds as per IPC-A-600K guidelines. In contrast, polyimide PCBs offer a broader polyimide PCB operating temperature range, making them suitable for high-temperature applications. Additionally, polyimide’s flexibility allows for innovative designs not possible with rigid FR-4, providing versatility in compact assemblies.

However, polyimide materials come with higher costs and processing challenges, requiring specialized manufacturing techniques. Engineers must weigh these factors against the benefits of enhanced polyimide PCB thermal management. For applications where thermal performance is paramount, such as in aerospace or industrial controls, the investment in polyimide often proves worthwhile due to reduced failure rates and extended lifespan.

Conclusion

Polyimide PCBs represent a significant advancement over traditional materials like FR-4, particularly in high-temperature applications. Their exceptional polyimide PCB thermal conductivity, wide polyimide PCB operating temperature range, and effective polyimide PCB heat dissipation make them indispensable in industries facing extreme conditions. For electric engineers working on polyimide PCB aerospace applications, understanding the material’s properties and implementing robust polyimide PCB thermal management strategies are key to success. By adhering to industry standards and leveraging thoughtful design practices, polyimide PCBs can deliver reliable performance where other materials fall short. This exploration underscores their importance in pushing the boundaries of electronic design for critical systems.

FAQs

Q1: How does polyimide PCB thermal conductivity compare to other materials?

A1: Polyimide PCB thermal conductivity is generally lower than that of metals but sufficient for high-temperature applications when paired with design optimizations. Standards like IPC-6012E guide the evaluation of thermal properties, ensuring even heat distribution. Compared to FR-4, polyimide excels in thermal stability, making it a better choice for environments where heat dissipation is critical.

Q2: What is the typical polyimide PCB operating temperature range?

A2: The polyimide PCB operating temperature range is notably wide, often surpassing the limits of standard epoxy materials as per IPC-A-600K testing protocols. This makes polyimide ideal for extreme conditions in aerospace and industrial settings. Engineers rely on such standards to validate performance under thermal stress, ensuring reliability in demanding applications.

Q3: Why are polyimide PCBs preferred in polyimide PCB aerospace applications?

A3: Polyimide PCBs are favored in polyimide PCB aerospace applications due to their ability to withstand extreme temperatures and mechanical stress. Their lightweight construction and thermal stability, as validated by IPC-6012E, align with aerospace requirements. This ensures consistent operation in avionics and satellite systems, where failure is not an option.

Q4: How can polyimide PCB heat dissipation be improved in design?

A4: Improving polyimide PCB heat dissipation involves strategic design choices like adding thermal vias and optimizing copper layouts. Following IPC-6012E guidelines ensures these methods are effective in preventing hotspots. Proper component spacing and external cooling solutions also enhance thermal management, maintaining performance in high-heat environments.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

JEDEC J-STD-020E — Moisture/Reflow Sensitivity Classification. JEDEC, 2014.