Why Is a Thoughtful Drone Flight Controller PCB Design So Important?

The flight controller functions as the central nervous system of a drone, orchestrating all critical operations from motor commands to the interpretation of sensor data. Therefore, the integrity of its printed circuit board (PCB) is paramount. A poorly conceived PCB can introduce a host of issues, such as erratic signal interference, dangerous overheating, or even a complete system failure during operation.

Conversely, a meticulously optimized drone flight controller PCB layout ensures seamless functionality, minimizes undesirable electrical noise, and guarantees enduring reliability. By applying careful planning and precise execution, designers can lay the groundwork for a robust and efficient system. The subsequent sections will delve into specific strategies to achieve these crucial design objectives.

What Are the Core Principles of an Effective Drone PCB Layout?

The physical arrangement of components on your PCB significantly influences a drone's overall performance. A well-executed drone flight controller PCB layout is engineered to reduce interference, facilitate efficient power distribution, and maintain a compact form factor. Adhering to specific guidelines is crucial for success.

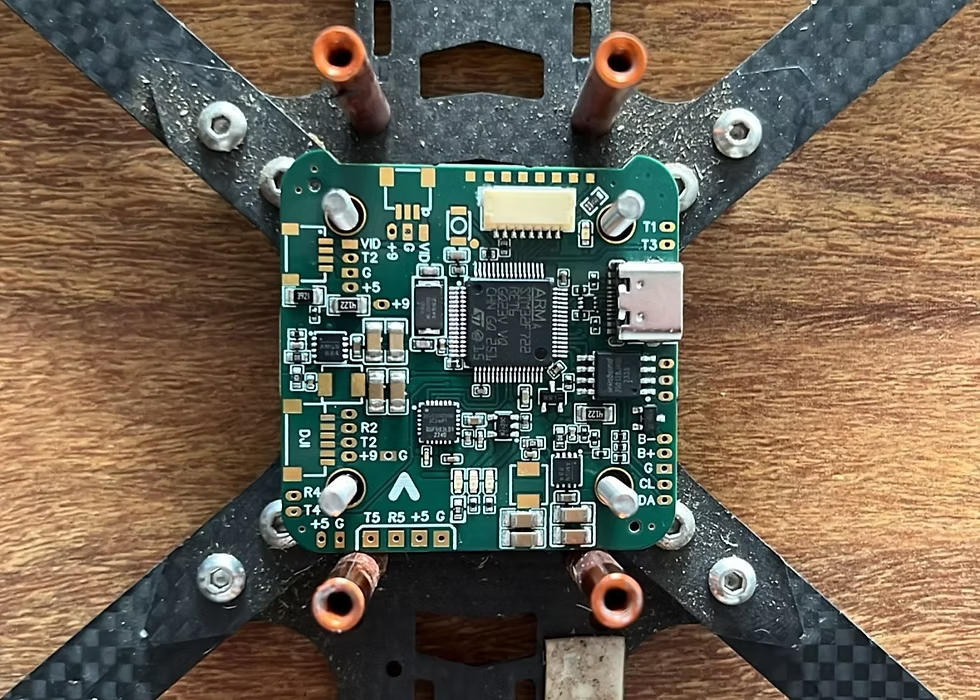

Strategic Component Placement

Critical components, such as the microcontroller, gyroscopes, and accelerometers, should be positioned centrally on the board to mitigate the impact of vibrations. High-speed signal components require close proximity to one another to shorten trace lengths and prevent signal propagation delays. For instance, maintaining connections between the Inertial Measurement Unit (IMU) and the main processor at less than 10 mm helps preserve data accuracy.

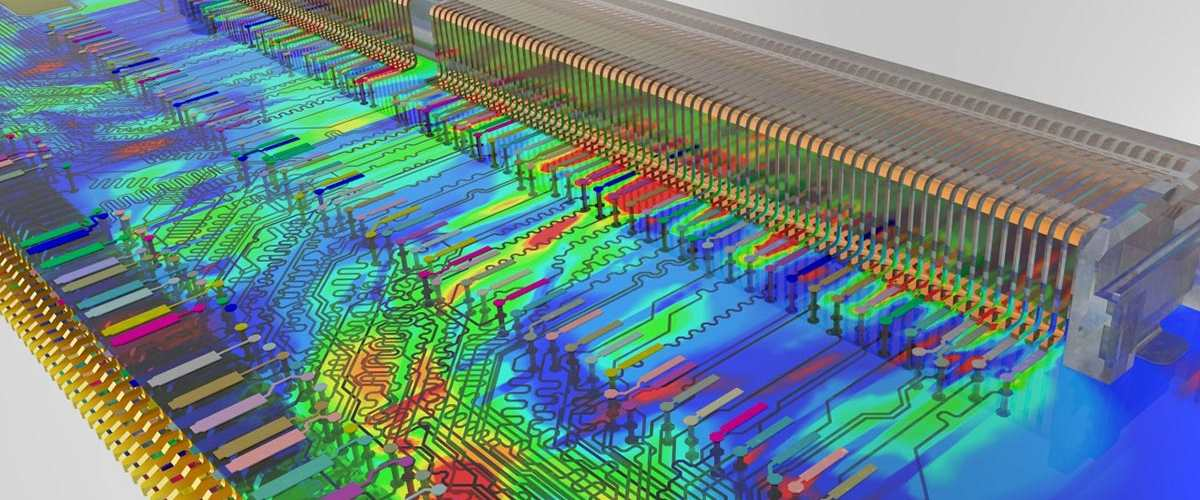

The Role of Ground Planes and Layer Stackup

Implementing a robust ground plane is essential for diminishing noise and providing a stable reference point for all signals. A continuous ground plane situated directly beneath high-frequency components can effectively decrease electromagnetic interference (EMI) by as much as 30%. For enhanced isolation and improved signal integrity, consider adopting a 4-layer PCB design, which typically includes dedicated layers for signals, ground, and power distribution.

Optimized Trace Routing Practices

High-speed traces, particularly those used for SPI or I2C communication, should be kept as short and direct as possible. It's vital to avoid routing traces across split ground planes, as this can introduce significant noise. Aiming for a trace impedance of approximately 50 ohms for high-speed signals is also recommended to ensure compatibility with component requirements and prevent reflections.

How Can You Guarantee Signal Integrity in Drone PCBs?

Ensuring drone PCB signal integrity is fundamental for accurate communication among components like sensors, processors, and Electronic Speed Controllers (ESCs). Compromised signal integrity can manifest as data errors, delayed responses, or unpredictable drone behavior. Implementing the following practices will help optimize signal flow.

Minimizing Crosstalk and Controlling Impedance

To prevent crosstalk, it's important to separate high-speed digital signals from analog signals with a clearance of at least three times the trace width. For example, a 0.2 mm trace width would require a 0.6 mm separation. Furthermore, matching the impedance of traces to the components they connect is crucial for high-speed lines such as USB or UART, where a 50-ohm impedance helps prevent signal reflections. Utilizing PCB design software equipped with impedance calculators can aid in achieving precise routing.

Decoupling Capacitors and Trace Length Management

Strategically placing decoupling capacitors near the power pins of integrated circuits (ICs) is vital for filtering out noise. A 0.1 μF capacitor positioned close to each power pin can significantly reduce voltage spikes by stabilizing the power supply. Additionally, long traces can inadvertently act as antennas, picking up unwanted noise; therefore, critical signal traces, especially those carrying high-frequency signals above 100 MHz, should ideally be kept under 25 mm.

What Are Effective Strategies for Drone PCB Thermal Management?

Drones frequently operate in challenging environments, where components such as processors and power regulators can generate substantial heat. Implementing effective drone PCB thermal management is crucial to prevent overheating, which can lead to premature component failure or a reduced operational lifespan. Several key strategies can help in dissipating this heat.

Utilizing Heat Sinks and Thermal Vias

For components that generate significant heat, like voltage regulators, incorporating thermal vias directly underneath them is an effective way to transfer heat to a lower layer or a dedicated heat sink. For instance, a component dissipating 2 watts of heat might require at least 4-6 thermal vias, each with a diameter of 0.3 mm.

Enhancing Dissipation with Copper Pours and Spacing

Increasing the copper area around heat-generating components serves as an excellent heat spreader. A copper pour with a thickness of 2 oz/ft2 can dissipate heat more efficiently than a standard 1 oz/ft2 layer. Furthermore, it's important to avoid clustering heat-generating components; spacing them out allows for better airflow and more uniform heat distribution across the entire board.

How Do Material Choices Impact Drone PCB Performance?

The selection of materials for a drone PCB significantly influences its performance, resilience, and weight. The appropriate materials must be capable of handling high frequencies, efficiently dissipating heat, and withstanding mechanical stresses encountered during flight.

Common and Advanced Laminates

FR-4 remains a popular choice for standard drone applications due to its cost-effectiveness and acceptable electrical properties, featuring a dielectric constant around 4.5 and thermal resistance up to 130°C. For drones requiring rapid data transmission, such as those with advanced GPS or video feeds, high-frequency laminates with lower dielectric constants (typically 3.0-3.5) are preferable to minimize signal loss. For extreme temperature resilience or flexible designs, polyimide offers excellent thermal stability, enduring up to 260°C, and is ideal for compact, flexible PCBs.

Selecting Optimal Copper Weight

For most drone PCBs, a copper weight of 1-2 oz/ft2 is typically recommended. While thicker copper enhances current-carrying capacity and improves heat dissipation, it also increases the overall weight of the board. Therefore, a careful balance must be struck to meet performance needs without compromising flight efficiency.

Strategies for Optimizing Drone PCB Weight Without Sacrificing Performance

Weight is a critical determinant in drone design, directly impacting flight duration and agility. Achieving optimal drone PCB weight requires strategic decisions that do not compromise performance.

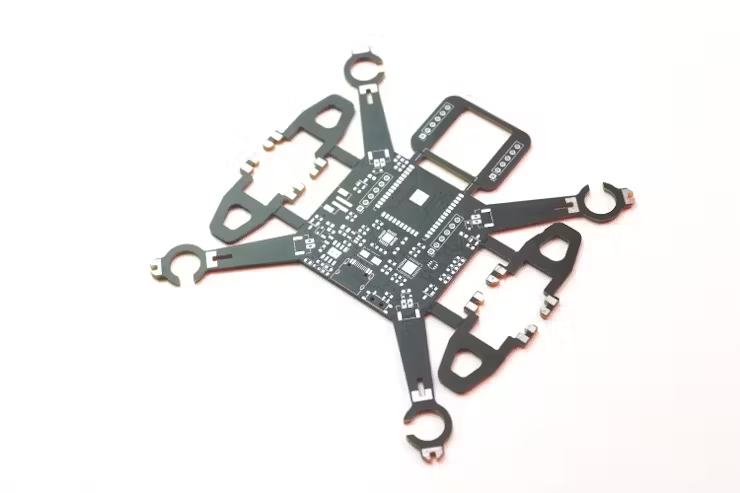

Board Miniaturization and Substrate Thickness

Designing a compact PCB is fundamental; this can involve vertically stacking components where feasible. A smaller board naturally uses less material and weighs less—for example, a 30x30 mm board is common for micro drones. Opting for thinner PCB substrates, such as 0.8 mm instead of 1.6 mm, can further reduce weight, provided the material still meets structural and thermal requirements.

Selective Copper Application and Material Removal

Employing thinner copper (e.g., 1 oz/ft2) in areas with low current demands, while reserving thicker copper (2 oz/ft2) only for high-current paths, like power lines to ESCs, helps balance weight and electrical needs. Additionally, strategically adding cutouts or slots in sections of the PCB where no components or traces are present can reduce the board's weight by 10-15% without affecting functionality.

What Additional Measures Ensure a Reliable Drone PCB Design?

Beyond the fundamental design aspects, several other best practices are vital for ensuring your drone flight controller PCB achieves both high performance and robust reliability.

Power Distribution and EMI Shielding

A resilient power distribution network is essential to manage the high currents common in quadcopters (often 20-50A). This involves using wide traces, ideally at least 2 mm for high-current paths, and multiple vias to minimize resistance. For sensitive components like GPS modules, incorporating EMI shielding—such as a small metal enclosure or a grounded copper pour—can effectively block external interference.

The Importance of Testing and Durability

Before proceeding to manufacturing, it is highly advisable to simulate your design for signal integrity, thermal performance, and power distribution using specialized PCB design tools. This proactive approach can identify potential issues early, preventing costly revisions. To further enhance durability and protect the PCB from moisture, dust, and vibration, especially for drones operating in harsh environments, applying a conformal coating is a critical final step.

Crafting the Future of Flight: Insights for Drone PCB Designers

Designing a drone flight controller PCB represents a challenging yet deeply gratifying endeavor. By prioritizing a well-conceived drone flight controller PCB layout, meticulously ensuring drone PCB signal integrity, mastering drone PCB thermal management, making informed selections for the best materials for drone PCB, and strategically optimizing drone PCB weight, designers can engineer a board that delivers unparalleled performance and unwavering reliability.

Every minute detail, from the precise placement of individual components to the thoughtful choice of substrate, contributes significantly to the final product's success. Equipped with the comprehensive strategies and actionable insights presented in this guide, you are now well-prepared to tackle the complexities of drone PCB design. Embrace these best practices in your upcoming projects, and witness your drone's capabilities ascend to extraordinary new levels.

AIVON, a professional online PCB manufacturer, is dedicated to supporting innovators like you, offering top-tier PCB manufacturing solutions specifically adapted to the evolving demands of drone technology. Let us collaborate in building the next generation of aerial innovation.