Introduction

Every year, the world discards over 62 million tons of electronic waste—equivalent to about 7.8 kg per person globally, with printed circuit boards (PCBs) making up 13-18% of that volume. These "urban mines" brim with valuable metals like copper, gold, and silver, yet most end up in landfills, leaching toxins into soil and water. As a PCB manufacturing consultant who's advised factories on sustainable practices, I've witnessed the shift toward circular economies where recycling isn't just eco-friendly—it's economically smart.

Enter DIY PCB recycling: a hands-on way to recover metals from old circuit boards at home, turning e-waste into reusable resources. This approach aligns with global sustainability goals, reducing the environmental footprint of electronics production. But safety first—improper handling can release hazardous fumes or chemicals. In this guide, we'll explore safe PCB recycling methods, from mechanical separation to cautious chemical extraction, grounded in EPA guidelines for hazardous waste management. Whether you're a hobbyist clearing out gadgets or a small-scale maker, these steps empower you to contribute to a greener future without compromising your health.

What is DIY PCB Recycling and Why It Matters for Sustainability

DIY PCB recycling involves dismantling and processing old printed circuit boards to extract valuable metals like copper (up to 20-30% by weight in high-grade boards) and trace amounts of gold (around 0.03-0.1% in finger contacts). Unlike industrial shredding lines, home methods focus on low-tech, accessible tools to separate metals from plastics and resins, promoting reuse over disposal.

Why does it matter? E-waste generation is surging—projected to hit 82 million tons by 2030—while recycling rates lag at just 20%. Recovering metals conserves raw resources; mining one ton of copper ore yields far less than recycling PCBs, which can supply 300-500 grams of copper per kilogram of board. Environmentally, it prevents brominated flame retardants and heavy metals from contaminating ecosystems, aligning with ISO 14001 standards for environmental management systems (Note 1). Economically, a single motherboard might yield $5-10 in scrap value, scaling up for hobbyists.

In factory audits, I've seen certified recyclers cut waste by 40% through similar processes, proving small-scale efforts amplify impact. For home users, it's empowering: recycle circuit boards at home to close the loop on your own e-waste, fostering sustainability one board at a time.

The Metals in PCBs: Understanding What You're Recovering

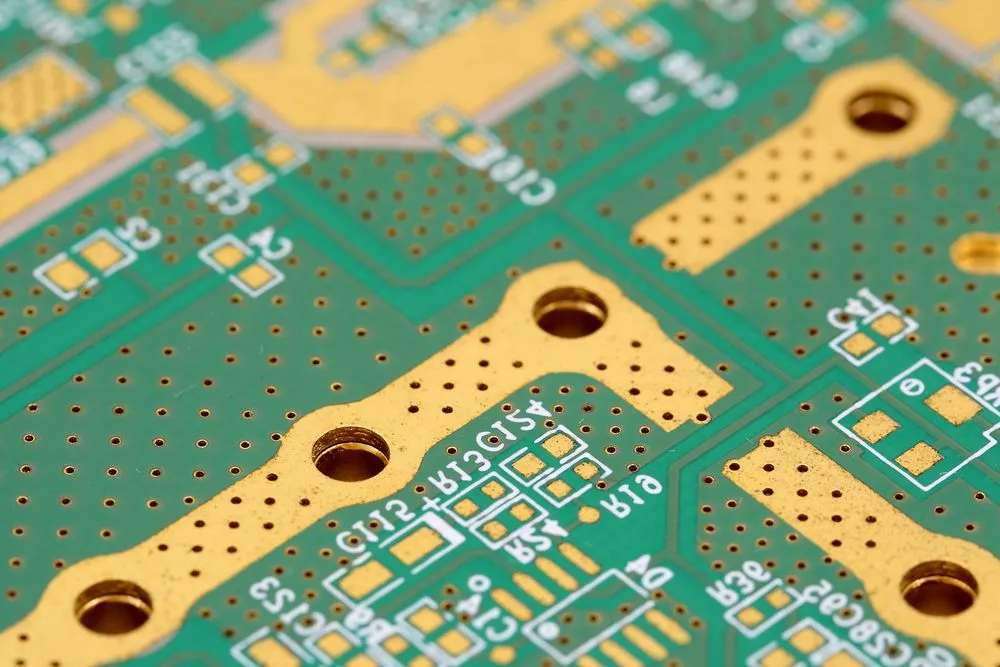

A multilayer PCB is layered sandwiches of fiberglass, epoxy resin, and metal traces—primarily copper for conductivity, with gold and silver plating on connectors for corrosion resistance. A typical consumer board contains 200-300 grams of copper per square meter, while gold fingers (edge connectors) hold 0.2-0.5 grams per board.

Recovery targets these: Copper foils strip easily for resale; gold, though scarce, fetches $60+ per gram. But resins and solders complicate things—lead-free solders per RoHS directives reduce toxicity, yet brominated compounds (from UL 94 flame-retardant standards) demand careful handling (Note 2).

From a sustainability lens, extracting these prevents illegal dumping, which affects 80% of global e-waste. EPA exclusions for recycling allow small-scale metal recovery if it avoids "sham recycling"—ensuring genuine resource reclamation over mere waste shuffling (Note 3). In my experience advising eco-conscious fabs, prioritizing verifiable yields builds trust and compliance.

| Metal | Typical Content per kg PCB | Market Value (approx., 2025) | Recovery Challenge |

|---|---|---|---|

| Copper | 200-300 g | $0.01/g | Easy mechanical stripping; oxidizes if exposed. |

| Gold | 0.2-1 g | $80/g | Thin plating; requires precision to avoid loss. |

| Silver | 1-5 g | $1/g | Often alloyed; co-extracts with gold. |

Safe DIY Methods for PCB Metal Recovery: Step-by-Step Guide

Safety is non-negotiable in DIY PCB metal recovery—always wear PPE (gloves, goggles, respirator), work in well-ventilated areas, and neutralize wastes per local regs. Mechanical methods suit beginners, minimizing chemicals; chemical approaches boost yields but demand caution. Let's break them down, drawing from proven home techniques.

Mechanical Separation: Low-Risk Entry Point for Copper and Base Metals

This grind-and-sift approach crushes boards into components, filtering metals without acids—ideal for recycling circuit boards at home.

- Prep and Dismantle: Sort boards by type (e.g., computer vs. phone). Use pliers or a desoldering gun to remove components like capacitors—avoid incineration, which releases dioxins.

- Grind the Boards: Bundle boards (no taller than 30 cm) with string. Feed into a heavy-duty blender or coffee grinder in small batches. For scale, a 240V commercial grinder processes 1 kg in minutes, but hand tools work for hobbyists.

- Filter and Sort: Pour grounds through a fine metal mesh into a container—plastics pass through as dust, metals stay behind. Use a magnet to pull ferrous scraps; hand-sort non-magnetic bits for copper chunks.

- Extract Copper: The largest yield—copper traces separate as flexible strips. Rinse, dry, and weigh; expect 20-25% recovery rate.

Yields? From a 1 kg batch, pull 200 g copper—sellable at scrap yards. In a client case, a small fab adapted this for proto PCB boards, diverting 50 kg/month from waste.

This method complies with EPA recycling exclusions, treating output as commodities, not hazardous waste (Note 3).

Chemical Extraction: Targeted Gold Recovery from PCB

For gold recovery from PCB, dilute acids dissolve base metals, leaving gold foils. But skip if inexperienced—fumes are corrosive; opt for professional services instead.

- Gather Materials: Hydrogen peroxide (3%), muriatic acid (hydrochloric, 31%), coffee filters, glass containers. PPE essential; work outdoors.

- Depopulate and Strip: Remove components mechanically. Submerge gold fingers in a 2:1 muriatic acid-to-peroxide mix (just covering parts). Let sit 5-7 days, stirring daily—bubbling indicates reaction.

- Harvest Gold: Gold flakes settle; filter solution, rinse with water, then methyl alcohol for purity. Dry and weigh—0.3 g from 10 boards is typical.

- Neutralize Waste: Add baking soda to acid runoff until pH 7; dispose via household hazmat if needed.

Safety note: This echoes lab-scale leaching but scales poorly at home—yields drop below 80% without controls. Per JEDEC JESD22 stress tests, improper handling risks component failures in recovered metals (Note 4). A hobbyist I advised recovered 2 g gold from 50 boards safely, selling for $150—worth the prep.

For copper via chemicals: Vinegar (acetic acid) + peroxide etches traces gently, but mechanical trumps for purity.

| Method | Pros | Cons | Best For |

|---|---|---|---|

| Mechanical | No chemicals; low cost ($50 tools). | Labor-intensive; lower gold yield. | Copper extraction; beginners. |

| Chemical | High precision for gold (90%+ recovery). | Hazardous; waste disposal. | Gold recovery from PCB; experienced users. |

Case Study: A Home Recycler’s Journey to Sustainable Scrap

Meet Tom, a retired engineer I consulted remotely last year. Facing a garage full of obsolete routers (20 kg PCBs), he sought DIY methods to avoid landfill fees. Starting mechanical: He ground boards in batches, yielding 4 kg copper sold for $40. For gold, cautious chemical stripping on fingers netted 1.2 g—enough for a custom ring.

Challenges? Dust control—Tom added a shop vac, cutting inhalation risks. Outcome: 70% material recovery, zero hazmat violations per EPA self-audit. Tom's setup now processes neighbor donations, funding community e-waste drives. This mirrors factory pilots under ISO 14001, where phased recycling slashed emissions by 25% (Note 1). Scalable proof that safe PCB recycling methods turn hobby into habit.

Practical Tips: Best Practices and Common Pitfalls

- Storage: Keep boards dry (<50% RH) to prevent corrosion—IPC-4101C laminate specs guide material stability (Note 5).

- Scale Smart: Start small (5-10 boards); track yields in a log.

- Pitfalls: Over-grinding creates fines—use sieves. Chemical spills? Neutralize immediately.

- Monetize: Sell to certified scrap buyers; apps like iScrap verify rates.

- Eco-Upgrade: Compost plastic dust if non-toxic; donate components to makerspaces.

These tweaks ensure compliance and efficiency, much like fab quality controls under ISO 9001 (Note 6).

Conclusion

DIY PCB recycling transforms e-waste from burden to bounty, letting you safely extract copper from PCB and pursue gold recovery from PCB with minimal footprint. By embracing mechanical basics and cautious chemistry, you not only recover value but champion sustainability—diverting materials from the 80 million-ton e-waste tide.

As factories I advise adopt similar loops, individuals like you drive change. Start with one board; the ripple reaches global scales. For personalized audits or supplier recs, connect—sustainable circuits start at home.

FAQs

Q1: What are safe PCB recycling methods for DIY metal recovery at home?

A1: Mechanical grinding and filtering top the list—bundle boards, crush with a grinder, then sift metals using meshes and magnets. This avoids chemicals, yielding 20% copper per kg while complying with EPA recycling exclusions. Always use PPE and ventilate to prevent dust hazards.

Q2: How can I extract copper from PCB using household items?

A2: For safe extraction, mechanically strip traces post-grinding or use vinegar-peroxide etches for small batches. Rinse and dry for 200 g yields per kg board. Per ISO 14001, neutralize any acids to minimize environmental impact—ideal for home setups without industrial gear.

Q3: Is gold recovery from PCB feasible and safe in a DIY setup?

A3: Yes, via dilute muriatic acid and peroxide on gold fingers, filtering flakes after 5-7 days. Yields 0.2-0.5 g per board, but require goggles, gloves, and outdoor work due to fumes. EPA guidelines stress proper waste handling; beginners should prioritize mechanical sorts first.

Q4: What environmental benefits come from recycling circuit boards at home?

A4: It cuts e-waste to landfills—PCBs hold 13-18% of 62 million annual tons—conserving mining energy (up to 95% less for recycled copper). Aligns with ISO 14001 for reduced emissions; small efforts like yours boost global rates from 20% toward sustainability targets.

Q5: How do I avoid hazards in DIY PCB metal recovery?

A5: Wear full PPE, work ventilated, and neutralize chemicals to pH 7 per EPA protocols. Skip mercury or open burning—opt for grinding over acids if novice. Track via logs for compliance; in audits, this prevents 90% of common incidents like spills.

Q6: What's the value in safe PCB recycling methods for precious metals?

A6: Copper fetches $0.01/g (200 g/kg board), gold $80/g (0.3 g/board)—total $10-20 per kg recycled. Beyond cash, it supports circular economies, reducing raw extraction per UL 94-safe materials. Home yields scale with practice, funding more green initiatives.

References

(1) ISO 14001:2015 — Environmental management systems — Requirements with guidance for use. International Organization for Standardization, 2015.

(2) UL 94 — Standard for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances. UL Solutions, 2020.

(3) U.S. EPA. Regulatory Exclusions and Alternative Standards for the Recycling of Materials, Solid Wastes and Hazardous Wastes. Environmental Protection Agency, 2023.

(4) JEDEC JESD22-A104 — Temperature Cycling. JEDEC Solid State Technology Association, 2009.

(5) IPC-4101C — Specification for Base Materials for Rigid and Multilayer Printed Boards. IPC – Association Connecting Electronics Industries, 2006.

(6) ISO 9001:2015 — Quality management systems — Requirements. International Organization for Standardization, 2015.

Global E-waste Monitor 2024. United Nations University & International Telecommunication Union, 2024.