Introduction

In the rapidly evolving electronics industry, managing heat in printed circuit boards (PCBs) has become a critical challenge. As devices shrink in size and power density increases, high temperature components demand innovative solutions for effective heat dissipation. Embedded copper structures have emerged as a powerful technique for extreme PCB thermal management, offering enhanced thermal conductivity and reliability. This approach addresses the limitations of traditional cooling methods, ensuring optimal performance in harsh environments. For electrical engineers, understanding these structures is essential to designing robust systems that withstand thermal stress. This article explores the principles behind embedded copper structures, their benefits, and practical implementation strategies for heat management options. By leveraging these advanced techniques, engineers can push the boundaries of PCB design for high power applications.

What Are Embedded Copper Structures and Why Do They Matter

Embedded copper structures refer to specialized copper elements integrated directly into the PCB substrate to improve thermal dissipation. These structures, often in the form of copper coins, blocks, or thick inner layers, act as heat spreaders or conduits, channeling thermal energy away from high temperature components. Unlike standard copper pours or vias, these features are strategically placed during the manufacturing process to target specific hotspots. Their significance lies in their ability to handle extreme thermal loads, which is crucial for modern electronics in automotive, aerospace, and industrial sectors.

The growing demand for compact, high performance devices has intensified the need for advanced PCB thermal management. Without proper heat control, components risk premature failure, reduced efficiency, and safety hazards. Embedded copper structures provide a direct path for heat transfer, minimizing thermal resistance and ensuring stable operation under high power conditions. For engineers, adopting these solutions means meeting stringent reliability requirements while maintaining design flexibility.

Technical Principles of Embedded Copper Structures in Thermal Management

The effectiveness of embedded copper structures in PCB thermal management stems from copper's exceptional thermal conductivity, approximately 400 W/mK, which far surpasses that of typical PCB FR4 material. These structures work by creating a low resistance thermal path from heat generating components to a larger dissipation area or external cooling mechanism. The principle is simple: heat flows from a high temperature zone to a lower temperature zone through the most conductive medium available.

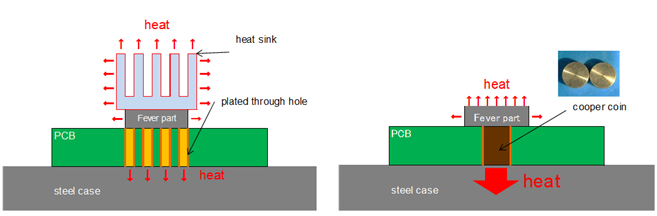

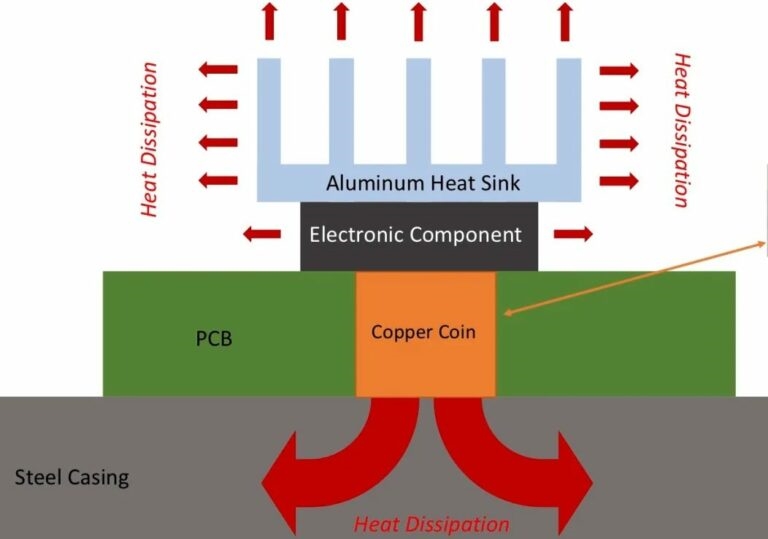

Copper coins, for instance, are cylindrical or rectangular inserts embedded into the fast turn PCB at critical locations, often directly beneath power intensive components. These coins connect to inner copper layers or external heat sinks, facilitating rapid heat transfer. Similarly, thick copper layers within the board can act as embedded heat spreaders, distributing thermal energy across a wider area to prevent localized overheating. The design must account for the thermal expansion mismatch between copper and surrounding materials to avoid mechanical stress, as outlined in standards like IPC-6012E.

Another key mechanism is the integration of these structures with thermal vias. Vias provide vertical heat paths, linking embedded copper to surface layers or external cooling solutions. This combination enhances overall thermal performance by creating a three dimensional heat dissipation network. Engineers must ensure precise alignment and bonding during manufacturing to maintain thermal and electrical integrity, adhering to guidelines in IPC-A-600K for acceptable board construction.

Benefits of Embedded Copper Structures for High Temperature Components

Embedded copper structures offer several advantages for managing heat in PCBs with high temperature components. First, they significantly reduce thermal resistance between the heat source and dissipation points, ensuring efficient cooling. This is particularly beneficial for power electronics, where components like MOSFETs and IGBTs generate substantial heat during operation. By minimizing temperature rise, these structures extend component lifespan and maintain performance.

Second, they allow for more compact designs. Traditional cooling methods, such as large external heat sinks, often require additional space, which conflicts with the trend toward miniaturization. Embedded solutions integrate thermal management directly into the board, preserving valuable real estate for other functionalities. This is critical in applications like mobile devices and automotive control units, where space constraints are paramount.

Lastly, these structures enhance reliability under extreme conditions. High temperature environments, common in industrial and aerospace applications, can degrade standard PCBs over time. Embedded copper provides a robust solution by stabilizing operating temperatures, reducing the risk of thermal fatigue and board warpage. Compliance with standards like JEDEC J-STD-020E ensures that designs can withstand moisture and reflow processes during assembly without compromising thermal performance.

Practical Solutions for Implementing Embedded Copper Structures

Implementing embedded copper structures requires careful planning during both design and manufacturing stages. Below are actionable strategies for electrical engineers to optimize PCB thermal management using these techniques.

Design Considerations

Start by identifying critical heat generating components on the board. Use thermal simulation tools to map temperature distribution and pinpoint hotspots. Place embedded copper structures, such as coins or blocks, directly beneath or near these areas to maximize heat transfer. Ensure that the size and shape of the copper insert match the thermal load and available board space. Additionally, integrate thermal vias to connect the embedded copper to outer layers or heat dissipation mechanisms.

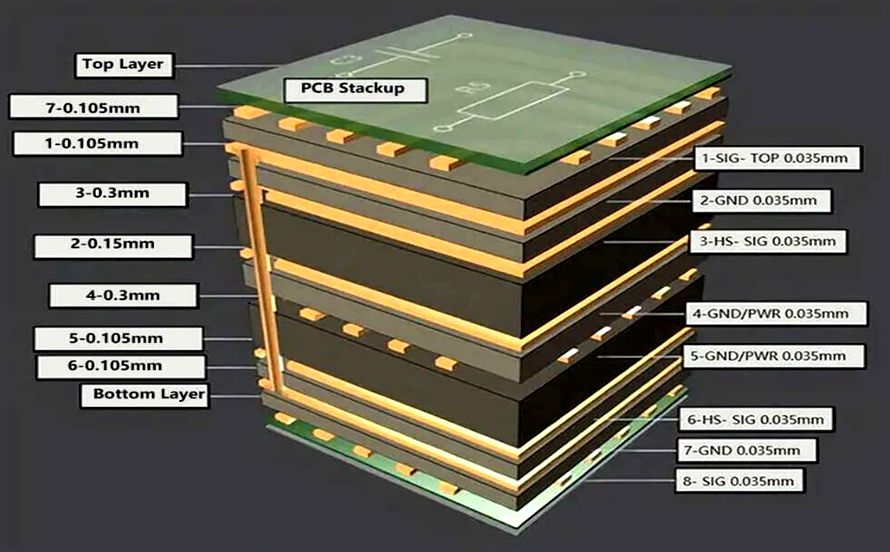

Pay attention to layer stackup design. Thicker inner copper layers can serve as heat spreaders, but they must be balanced with signal integrity requirements. Follow guidelines in IPC-6012E for specifying copper thickness and placement to avoid manufacturing defects. Account for the coefficient of thermal expansion to prevent delamination or cracking during temperature cycles.

Manufacturing Challenges and Solutions

Manufacturing PCBs with embedded copper structures demands precision. The process involves milling cavities in the substrate to accommodate copper inserts, followed by secure bonding to ensure thermal contact. Misalignment or poor adhesion can create thermal barriers, negating the benefits. Adhere to IPC-A-600K standards for acceptable board construction and inspect for voids or defects post fabrication.

Collaboration between design and manufacturing teams is essential. Specify tolerances and material requirements clearly in design files to avoid errors. Consider the impact of additional processing steps on overall cost and lead time, ensuring that the chosen solution aligns with project constraints.

Integration with Other Heat Management Options

Embedded copper structures can be combined with other heat management options for enhanced performance. Pair them with external heat sinks or cooling fans to dissipate heat beyond the board level. Use thermally conductive adhesives or pads to improve contact between components and embedded copper. In high power designs, consider metal core PCBs alongside embedded structures for superior thermal conductivity across the entire board.

(Insert image: 'PCB with Embedded Copper and Heat Sink' · ALT: 'PCB design showing embedded copper structure connected to an external heat sink')

Troubleshooting Common Issues with Embedded Copper Structures

Despite their advantages, embedded copper structures can present challenges if not implemented correctly. One common issue is mechanical stress due to thermal expansion mismatch between copper and the surrounding substrate. This can lead to cracking or delamination over time, especially in high temperature environments. To mitigate this, select substrate materials with compatible thermal expansion properties and follow design rules in IPC-6012E for stress relief.

Another concern is manufacturing variability. Improper bonding of copper inserts can create air gaps, reducing thermal efficiency. Rigorous quality control, aligned with IPC-A-600K, helps detect such defects early. Engineers should also verify that the embedded structures do not interfere with electrical performance, particularly in high frequency designs where copper placement might affect signal integrity.

Finally, cost can be a limiting factor. Embedding copper adds complexity to the manufacturing process, increasing production expenses. Balance the thermal benefits against budget constraints, reserving this technique for applications where extreme PCB thermal management is non negotiable, such as in power converters or LED lighting systems.

(Insert image: 'Thermal Stress Analysis on PCB' · ALT: 'Simulation output showing thermal stress distribution around embedded copper in a PCB')

Conclusion

Embedded copper structures represent a transformative approach to extreme PCB thermal management, addressing the challenges posed by high temperature components in modern electronics. By leveraging copper's superior thermal conductivity, these structures provide efficient heat dissipation, enabling compact and reliable designs for demanding applications. Electrical engineers can implement these solutions through careful design, precise manufacturing, and integration with other heat management options. Adhering to established industry standards ensures that the benefits of embedded copper are realized without compromising board integrity. As power densities continue to rise, mastering these techniques will be crucial for pushing the limits of PCB performance in high stakes environments.

FAQs

QX: How do embedded copper structures improve PCB thermal management?

AX: Embedded copper structures enhance PCB thermal management by providing a direct, low resistance path for heat transfer from high temperature components to dissipation areas. Their high thermal conductivity reduces temperature rise at hotspots, preventing component damage. Positioned strategically within the board, they support compact designs while maintaining reliability, adhering to standards like IPC-6012E for optimal performance in high power applications.

QX: What are the challenges of using embedded copper for heat management options?

AX: Implementing embedded copper for heat management options involves challenges like thermal expansion mismatch, which can cause mechanical stress or cracking. Manufacturing precision is critical to avoid air gaps that reduce efficiency. Costs are also higher due to complex processes. Following guidelines in IPC-A-600K during fabrication helps address quality issues, ensuring effective thermal performance in demanding environments.

QX: Can embedded copper structures support high temperature components in harsh conditions?

AX: Yes, embedded copper structures are well suited for high temperature components in harsh conditions. They efficiently dissipate heat, stabilizing operating temperatures and extending component life in industrial or aerospace applications. Their design minimizes thermal fatigue, provided they comply with standards like JEDEC J-STD-020E for moisture and reflow resilience, making them reliable for extreme thermal environments.

QX: What design tools help optimize embedded copper for PCB thermal management?

AX: Thermal simulation software is vital for optimizing embedded copper in PCB thermal management. These tools map heat distribution, identify hotspots, and guide the placement of copper structures. They ensure compatibility with board layout and signal integrity. While specific tools vary, following design principles in IPC-6012E helps engineers create effective thermal paths for high power designs without compromising performance.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

JEDEC J-STD-020E — Moisture/Reflow Sensitivity Classification. JEDEC, 2014.