Introduction

High Density Interconnect (HDI) Printed Circuit Boards (PCBs) are integral to modern electronics, enabling compact designs with enhanced functionality in devices like smartphones, medical equipment, and automotive systems. As the complexity of HDI PCBs increases with finer lines, smaller vias, and multiple layers, maintaining quality becomes a critical challenge for electrical engineers. Effective HDI PCB quality control methods ensure reliability, performance, and compliance with stringent industry standards. This article explores the inspection criteria, testing techniques, and best practices for achieving consistent quality in HDI PCB production. From material selection to final testing, understanding these processes is essential for engineers aiming to deliver robust and high performing circuit boards in demanding applications.

What Are HDI PCBs and Why Quality Control Matters

HDI PCBs are characterized by their high wiring density, achieved through microvias, fine pitch traces, and multiple stacked layers. These boards support advanced electronic designs by reducing size and weight while increasing signal integrity and speed. However, their intricate structure makes them prone to defects like microvia failures, trace discontinuities, and layer misalignment. Poor quality can lead to signal loss, thermal issues, or complete system failure, impacting product reliability and safety.

Quality control in HDI PCB manufacturing is vital to detect and prevent such issues early. It ensures that boards meet performance specifications and adhere to industry standards. For electrical engineers, rigorous HDI PCB inspection criteria and testing methods are non negotiable to guarantee functionality in high stakes environments such as aerospace or medical fields, where failure is not an option.

Technical Principles of HDI PCB Quality Control

Quality control for HDI PCBs involves a systematic approach to monitor every stage of production, from design validation to final assembly. The primary focus areas include material integrity, dimensional accuracy, and electrical performance. Below are the key principles guiding HDI PCB quality control methods.

Material Selection and Verification

The foundation of HDI PCB reliability lies in selecting appropriate materials. Base laminates, copper foils, and dielectric layers must withstand thermal and mechanical stresses during operation. Quality control starts with verifying material properties against recognized standards such as IPC 4101, which outlines specifications for laminate materials used in PCBs. Testing for thermal stability, moisture absorption, and dielectric constant ensures that materials will perform under specified conditions.

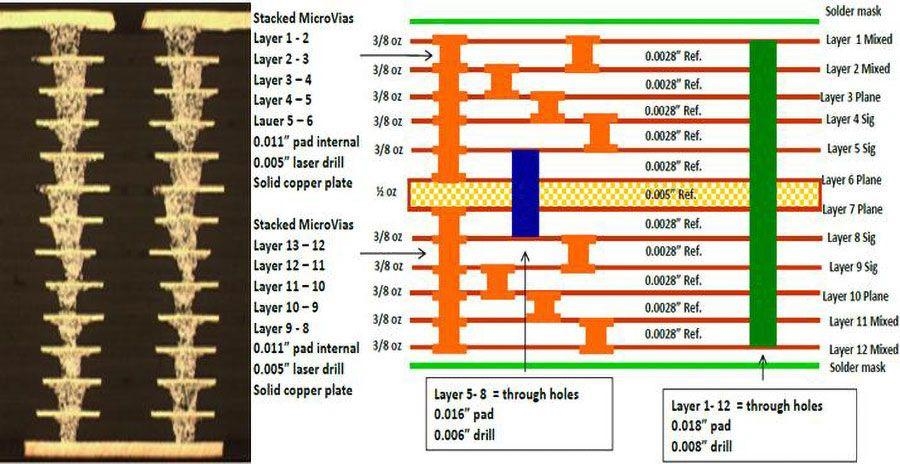

Dimensional and Structural Integrity

HDI PCBs often feature microvias with diameters below 150 micrometers and trace widths under 100 micrometers. Precision in drilling, etching, and lamination is crucial to maintain structural integrity. Inspection criteria based on IPC A 600K, which defines acceptability standards for printed boards, help engineers evaluate aspects like via alignment, layer registration, and surface finish. Deviations in these parameters can cause open circuits or shorts, undermining board performance.

Electrical Performance and Signal Integrity

Electrical testing focuses on verifying continuity, insulation resistance, and impedance control, especially critical for high speed signals in HDI designs. Standards like IPC 9252 provide guidelines for electrical test requirements, ensuring that boards meet performance benchmarks. Signal integrity issues, such as crosstalk or reflection, often stem from inconsistent trace geometry or dielectric properties, making electrical testing a cornerstone of quality control.

HDI PCB Inspection Criteria

Inspection criteria for HDI PCBs are derived from widely accepted industry standards to ensure consistency and reliability. These criteria cover visual, dimensional, and functional aspects of the board. Below are the primary categories of inspection for HDI PCBs.

Visual Inspection Standards

Visual inspection, guided by IPC A 600K, assesses surface defects, solder mask coverage, and marking clarity. Engineers look for issues like scratches, voids in plating, or incomplete solder mask application. For HDI PCBs, special attention is given to microvia formation and surface flatness, as even minor flaws can affect assembly and performance.

Dimensional Inspection

Dimensional checks verify the accuracy of features like via sizes, trace widths, and board thickness. Tools such as optical comparators and coordinate measuring machines are used to ensure compliance with design specifications. IPC 6012E, which specifies performance requirements for rigid PCBs, provides detailed acceptance criteria for these measurements, ensuring structural reliability.

Microvia and Layer Registration

Microvias and layer alignment are critical in HDI designs due to their stacked structure. Inspection often involves cross sectioning and microscopic analysis to check via integrity and interlayer connections. Misalignment or incomplete via filling can lead to reliability issues, making adherence to IPC 2226 guidelines for HDI design and manufacturing essential.

HDI PCB Testing Methods

Testing is a fundamental component of HDI PCB quality control, focusing on identifying defects that inspections might miss. These methods validate both mechanical and electrical properties, ensuring boards meet operational demands. Below are key HDI PCB testing approaches.

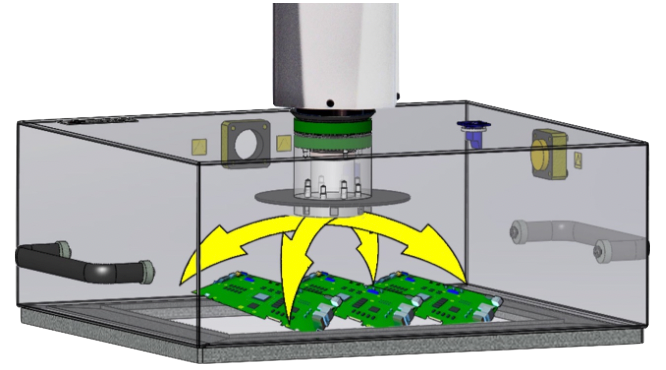

Automated Optical Inspection (AOI)

AOI systems use high resolution cameras to detect surface defects like missing traces or solder mask irregularities. This non contact method is efficient for high volume production, allowing engineers to identify issues early in the manufacturing process. It complements manual visual checks by providing consistent and repeatable results.

X Ray Inspection

X ray imaging is indispensable for inspecting internal structures of HDI PCBs, particularly microvias and buried layers. It reveals defects like voids, cracks, or incomplete via filling that are invisible to the naked eye. This method ensures compliance with structural integrity standards outlined in IPC 6012E.

Electrical Testing

Electrical testing verifies circuit continuity and insulation resistance using methods like flying probe or bed of nails testing. Impedance testing is also crucial for high speed HDI designs to ensure signal integrity. Guidelines from IPC 9252 help define test parameters, ensuring boards perform reliably under specified electrical conditions.

Thermal and Environmental Testing

HDI PCBs often operate in harsh environments, requiring testing for thermal cycling and humidity resistance. Standards like IPC TM 650 provide methodologies for evaluating board performance under stress. These tests simulate real world conditions to predict long term reliability and prevent failures in the field.

Best Practices for HDI PCB Quality Control

Implementing effective quality control for HDI PCBs requires a proactive approach, integrating best practices across design, manufacturing, and testing phases. Electrical engineers can adopt the following strategies to enhance reliability and performance.

Design for Manufacturability (DFM)

Incorporate DFM principles during the design stage to minimize manufacturing challenges. This includes optimizing microvia placement, ensuring adequate trace spacing, and selecting compatible materials. Adhering to IPC 2226 guidelines for HDI design helps avoid common pitfalls that lead to quality issues.

Process Monitoring and Control

Continuous monitoring of manufacturing processes, such as etching, drilling, and lamination, prevents deviations that affect quality. Statistical process control techniques can identify trends or anomalies, allowing for timely corrective actions. Compliance with ISO 9001:2015 for quality management systems supports consistent process execution.

Collaboration Across Teams

Effective communication between design, manufacturing, and testing teams ensures that quality requirements are understood and met at every stage. Sharing inspection data and test results fosters a collaborative environment, reducing the risk of overlooked defects in HDI PCB production.

Challenges in HDI PCB Quality Control and Solutions

HDI PCBs present unique challenges due to their complexity, such as detecting internal defects or managing tight tolerances. One common issue is microvia reliability, where poor drilling or plating can lead to connection failures. Using advanced X ray inspection and adhering to IPC 6012E criteria can mitigate this risk by ensuring via integrity.

Another challenge is maintaining signal integrity in high speed designs. Inconsistent impedance or crosstalk can degrade performance. Electrical testing based on IPC 9252 standards, combined with precise design practices, helps address these issues. Engineers should also prioritize material selection to match dielectric properties with design requirements.

Conclusion

Quality control for HDI PCBs is a multifaceted process that demands attention to detail, adherence to industry standards, and the use of advanced testing methods. By implementing robust HDI PCB quality control methods and inspection criteria, electrical engineers can ensure reliability and performance in complex electronic systems. From material verification to electrical testing, each step plays a critical role in delivering boards that meet stringent demands. Staying aligned with standards like IPC 6012E and IPC A 600K provides a solid foundation for consistent quality, enabling innovation in high density interconnect designs.

FAQs

Q1: What are the key HDI PCB quality control methods for ensuring reliability?

A1: HDI PCB quality control methods include material verification, dimensional inspection, and electrical testing. Automated optical inspection and X ray imaging detect surface and internal defects, while thermal testing assesses durability. Following standards like IPC 6012E ensures structural integrity. These methods collectively ensure that HDI PCBs perform reliably in demanding applications.

Q2: How do HDI PCB inspection criteria impact manufacturing outcomes?

A2: HDI PCB inspection criteria, based on standards like IPC A 600K, define acceptable limits for visual, dimensional, and structural features. They guide engineers in identifying defects like misaligned layers or flawed microvias. Meeting these criteria prevents manufacturing errors, reduces rework, and ensures the final product meets design specifications for optimal performance.

Q3: What types of HDI PCB testing are essential for high speed designs?

A3: For high speed HDI designs, electrical testing for impedance control and signal integrity is critical. Flying probe or bed of nails tests verify continuity and insulation. Thermal cycling tests, guided by IPC TM 650, assess performance under stress. These testing methods ensure the board supports high frequency signals without degradation.

Q4: Why are industry standards important in HDI PCB quality control?

A4: Industry standards like IPC 9252 and IPC 2226 provide consistent guidelines for testing and design. They ensure uniformity in HDI PCB quality control across manufacturing processes. Compliance guarantees reliability, interoperability, and safety in applications. For engineers, these standards are a benchmark to validate performance and maintain trust in complex systems.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

IPC-9252 — Requirements for Electrical Testing of Unpopulated Printed Boards. IPC, 2016.

IPC-2226 — Sectional Design Standard for High Density Interconnect (HDI) Printed Boards. IPC, 2003.

IPC-4101E — Specification for Base Materials for Rigid and Multilayer Printed Boards. IPC, 2017.

IPC-TM-650 — Test Methods Manual. IPC, 2021.

ISO 9001:2015 — Quality Management Systems. ISO, 2015.