Introduction

In the field of electronics design, selecting the right printed circuit board material is critical for ensuring reliability and performance. High Tg PCBs, characterized by their elevated glass transition temperature, offer distinct advantages over standard PCBs in demanding environments. For electrical engineers, understanding when to opt for high Tg materials over conventional options can prevent failures in high temperature applications. This article explores the core differences between high Tg PCB benefits and standard PCB limitations, alongside high Tg PCB cost considerations and high Tg PCB applications. By delving into technical principles and practical scenarios, this guide aims to equip engineers with the knowledge to make informed decisions for their projects, ensuring optimal functionality under challenging conditions.

What Is High Tg PCB and Why It Matters

High Tg PCB refers to a printed circuit board made with materials that have a higher glass transition temperature, often above 170 degrees Celsius. The glass transition temperature, or Tg, is the point at which a PCB substrate transitions from a rigid to a more pliable state. For standard PCBs, Tg values typically range around 130 to 140 degrees Celsius, which may not suffice in extreme conditions. High Tg materials maintain structural integrity at elevated temperatures, making them vital for applications where thermal stress is a concern.

The relevance of high Tg PCBs in the industry cannot be overstated. As electronic devices become more compact and power dense, they generate significant heat. Without adequate thermal stability, boards can warp, delaminate, or suffer from degraded electrical performance. High Tg PCB benefits include enhanced durability and reliability, ensuring that critical systems in automotive, aerospace, and industrial sectors operate without interruption. For electrical engineers, choosing the right Tg value directly impacts the longevity and safety of their designs.

Technical Principles Behind High Tg PCB and Standard PCB Differences

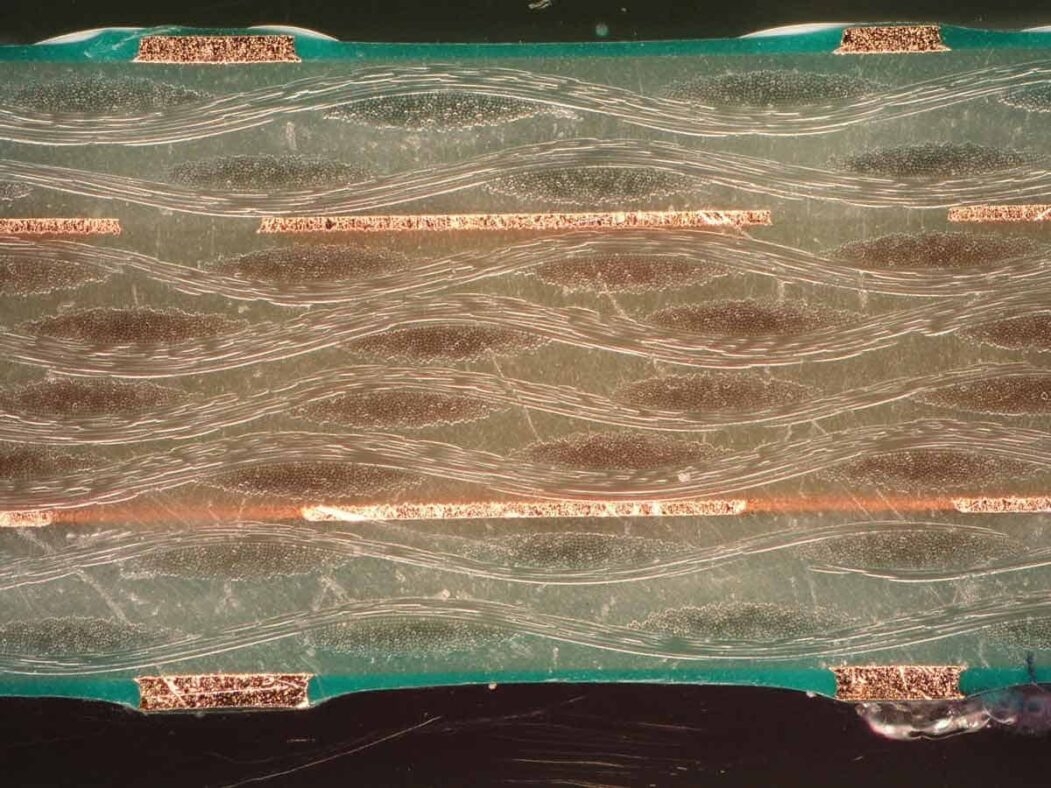

The primary distinction between high Tg PCBs and standard PCBs lies in their material composition and thermal behavior. Standard PCBs often use FR-4 laminates with moderate Tg values, suitable for general purpose electronics. These materials consist of woven fiberglass reinforced with epoxy resin, providing a balance of cost and performance. However, under prolonged exposure to temperatures near or above their Tg, these boards risk losing mechanical strength, leading to issues like warpage or cracking.

High Tg PCBs, on the other hand, incorporate advanced epoxy formulations or alternative resins with improved cross linking density. This results in a higher resistance to thermal expansion and better dimensional stability. According to industry standards such as IPC-6012E, high Tg materials are specified for applications requiring enhanced thermal endurance. Their ability to withstand heat also reduces the coefficient of thermal expansion, minimizing stress on vias and solder joints during temperature cycling.

Electrically, high Tg materials often exhibit lower dielectric loss at high frequencies, which is crucial for signal integrity in advanced circuits. While standard PCB limitations include susceptibility to moisture absorption and chemical degradation, high Tg options offer improved resistance to these factors. Understanding these material properties allows engineers to predict board behavior under specific operating conditions and select accordingly.

Standard PCB Limitations in Demanding Environments

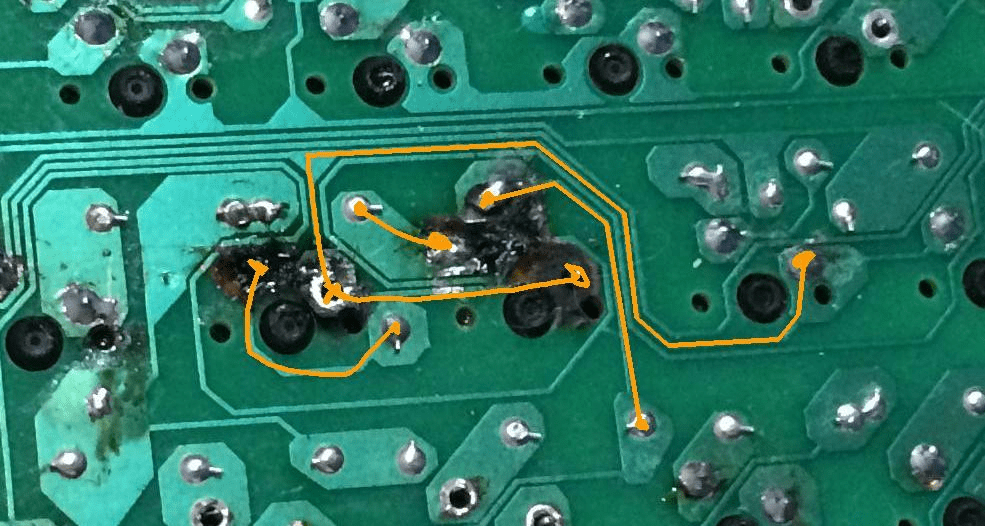

Standard PCBs, while cost effective and widely used, have inherent constraints that can compromise performance in rigorous applications. One major limitation is their lower thermal threshold. When exposed to temperatures approaching their Tg, these boards can soften, leading to mechanical failures. This is particularly problematic in environments with frequent thermal cycling, where repeated expansion and contraction stress the board structure.

Another issue is their limited chemical resistance. Standard FR-4 materials can absorb moisture, which alters dielectric properties and may cause delamination over time. In high humidity or corrosive settings, this vulnerability can lead to short circuits or insulation breakdown. Additionally, standard PCBs often struggle with high frequency signal transmission due to higher dielectric losses, impacting performance in modern communication systems.

For applications involving lead free soldering, which requires higher reflow temperatures as per JEDEC J-STD-020E, standard PCBs may not withstand the thermal load. This can result in pad cratering or via barrel cracking, reducing reliability. Electrical engineers must recognize these standard PCB limitations to avoid design flaws in critical systems where failure is not an option.

High Tg PCB Benefits for Enhanced Performance

High Tg PCBs address many of the shortcomings of standard boards, offering substantial benefits for specialized applications. Their primary advantage is superior thermal stability. By maintaining rigidity at higher temperatures, these boards prevent warpage and ensure consistent performance in heat intensive environments. This is essential for devices operating in industrial control systems or automotive electronics, where ambient temperatures can spike significantly.

Beyond thermal endurance, high Tg PCB benefits include improved mechanical strength. The enhanced material properties reduce the risk of cracking under physical stress or vibration, a common concern in aerospace and military hardware. Additionally, these boards exhibit better resistance to moisture and chemicals, extending their lifespan in harsh conditions. This aligns with quality requirements outlined in IPC-A-600K for printed board acceptability.

From an electrical perspective, high Tg materials support high frequency applications with lower signal loss, ensuring data integrity in telecommunications equipment. Their compatibility with lead free soldering processes also makes them suitable for modern manufacturing standards. For engineers, leveraging these benefits can significantly enhance the reliability of their designs, particularly in mission critical scenarios.

High Tg PCB Cost Considerations

While high Tg PCB benefits are clear, cost remains a critical factor in material selection. High Tg materials generally involve higher raw material expenses due to their specialized formulations. The manufacturing process may also require more precise control of lamination and curing parameters, adding to production costs. For complex multilayer designs, these expenses can accumulate, impacting overall project budgets.

However, the initial high Tg PCB cost must be weighed against long term savings. By reducing failure rates and extending service life, these boards can lower maintenance and replacement expenses. In applications where downtime is costly, such as industrial automation, investing in high Tg PCBs often proves economical over time. Engineers should conduct a thorough cost benefit analysis, considering both upfront expenditures and potential risks of using standard materials in unsuitable conditions.

It is also worth noting that not all projects require high Tg materials. For low power consumer electronics with minimal thermal stress, standard PCBs remain a viable and budget friendly option. Balancing performance needs with financial constraints is key to making an informed decision in PCB selection.

High Tg PCB Applications in Key Industries

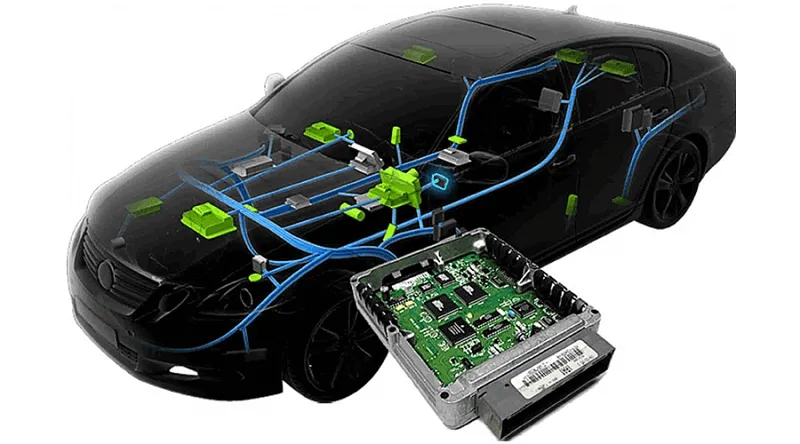

High Tg PCB applications span a variety of industries where thermal and mechanical reliability are paramount. In the automotive sector, these boards are used in engine control units and power management systems, where they must endure high under hood temperatures. Their ability to resist thermal cycling ensures consistent operation over the vehicle’s lifespan.

In aerospace and defense, high Tg PCBs are critical for avionics and radar systems. These environments demand materials that can withstand extreme temperatures and vibrations without compromising signal integrity. Compliance with stringent standards like IPC-6012E is often mandatory in such applications, making high Tg materials a preferred choice.

Industrial electronics also benefit from high Tg PCBs, particularly in equipment exposed to harsh factory conditions. From motor drives to power inverters, these boards provide the durability needed for continuous operation. Telecommunications infrastructure, including base stations and routers, relies on high Tg materials to handle high frequency signals and elevated operating temperatures without degradation.

When to Switch to High Tg PCB

Deciding when to transition from standard PCBs to high Tg options depends on specific project requirements. Engineers should consider operating temperature ranges first. If a device will be exposed to conditions near or above the Tg of standard materials, switching to high Tg PCBs is advisable to prevent structural failures.

Another factor is the soldering process. Lead free soldering, which aligns with environmental regulations, often involves peak temperatures that standard boards cannot handle. High Tg materials are better suited to these processes, ensuring integrity during assembly as per JEDEC J-STD-020E guidelines. Additionally, applications involving high power densities or frequent thermal cycling warrant the use of high Tg PCBs to maintain reliability.

Environmental conditions also play a role. In settings with high humidity or chemical exposure, high Tg materials offer superior resistance, reducing the risk of performance issues. Finally, for high frequency circuits where signal loss is a concern, high Tg PCBs provide the necessary electrical properties to support data transmission. Assessing these criteria helps engineers determine the optimal material for their designs.

Conclusion

Selecting between high Tg PCBs and standard PCBs is a pivotal decision for electrical engineers aiming to balance performance, reliability, and cost. High Tg PCB benefits, such as thermal stability and mechanical strength, make them indispensable in demanding high Tg PCB applications like automotive and aerospace systems. Conversely, standard PCB limitations highlight their unsuitability for extreme conditions, guiding engineers to opt for high Tg materials when necessary. While high Tg PCB cost may be higher initially, the long term advantages often justify the investment in critical projects. By evaluating operating environments and design requirements, engineers can make strategic choices that enhance the durability and functionality of their electronic systems.

FAQs

QX: What are the main high Tg PCB benefits for electrical engineers?

AX: High Tg PCB benefits include superior thermal stability, allowing boards to withstand elevated temperatures without deforming. They also offer enhanced mechanical strength and chemical resistance, ensuring reliability in harsh environments. For engineers, this translates to fewer failures in high stress applications like industrial controls, as outlined in standards such as IPC-A-600K.

QX: How does high Tg PCB cost compare to standard PCBs in long term projects?

AX: High Tg PCB cost is typically higher due to specialized materials and manufacturing processes. However, for long term projects, they can reduce expenses by minimizing failures and extending lifespan. Engineers must assess initial budgets against potential downtime costs to determine if the investment aligns with project goals.

QX: What are common standard PCB limitations in high temperature settings?

AX: Standard PCB limitations include a lower glass transition temperature, leading to warpage or delamination under heat. They also have reduced chemical resistance and higher dielectric loss, impacting performance. In high temperature settings, these issues can cause reliability problems, making them unsuitable per IPC-6012E guidelines.

QX: Where are high Tg PCB applications most critical for reliable performance?

AX: High Tg PCB applications are critical in automotive, aerospace, and industrial sectors. These environments demand thermal endurance for systems like engine controls and avionics. Their ability to handle heat and vibration ensures consistent operation, meeting rigorous standards and protecting mission critical functionality.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

JEDEC J-STD-020E — Moisture/Reflow Sensitivity Classification. JEDEC, 2014.