Introduction

In the realm of modern electronics, high power multilayer printed circuit boards (PCBs) are integral to applications ranging from industrial machinery to advanced telecommunications. These designs often handle substantial electrical loads, generating significant heat that can compromise performance and reliability if not managed effectively. Thermal management becomes a critical aspect to ensure component longevity and system stability. This article explores the challenges of heat dissipation in high power PCB designs and offers practical strategies for engineers. Key areas such as heat sink integration, thermal vias usage, material selection for high temperature environments, and advanced cooling techniques will be discussed to equip professionals with the tools needed for optimal thermal performance in complex multilayer boards.

Why Heat Management Matters in High-Power PCBs

High power PCB thermal management is essential because excessive heat can degrade components, reduce operational lifespan, and cause system failures. In multilayer designs, where components are densely packed across multiple layers, heat accumulation is a pressing concern. Elevated temperatures can alter electrical properties, leading to signal integrity issues or complete circuit malfunction. Moreover, thermal stress may induce mechanical failures like delamination or cracking in the board structure. Effective heat dissipation ensures that operating temperatures remain within safe limits, preserving performance and reliability. For engineers, understanding and implementing robust thermal solutions is not just a design consideration but a fundamental requirement to meet industry standards and application demands.

Technical Principles of Heat Generation in Multilayer PCBs

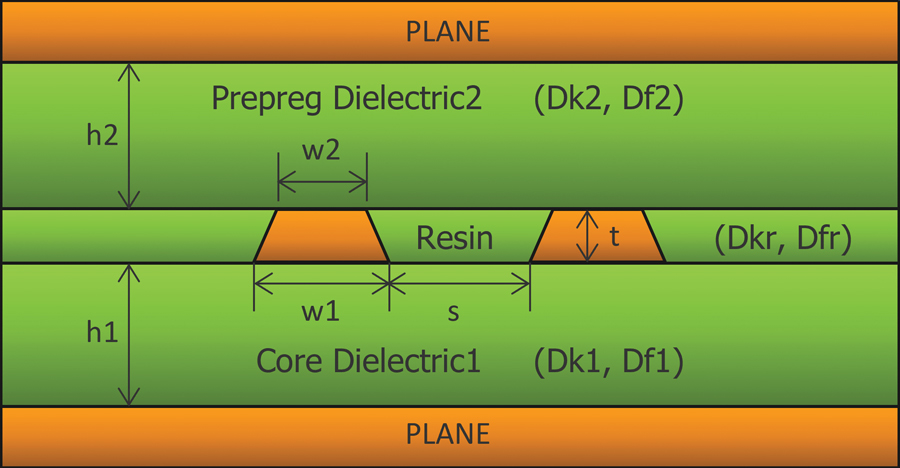

Heat in high power PCBs primarily arises from power dissipation in active components like transistors, integrated circuits, and resistors. When current flows through these elements, energy loss manifests as heat due to resistance. In the multilayer circuit board, the stacking of conductive layers and insulating substrates complicates heat transfer, often trapping thermal energy within internal layers. The limited surface area for natural convection exacerbates this issue, especially in compact designs. Additionally, high frequency operations can increase dielectric losses, further contributing to temperature rise. Understanding these mechanisms is crucial for identifying heat sources and predicting thermal behavior. Engineers must consider factors like power density, layer count, and component placement to model heat distribution accurately and devise effective mitigation strategies.

Material Selection for High Temperature Environments

Choosing the right PCB material for high temperature applications is a foundational step in thermal management. The standard PCB FR-4 material may suffice for low power designs, but high power multilayer boards often require substrates with superior thermal conductivity and stability. Materials with enhanced properties can withstand elevated temperatures without degrading, ensuring structural integrity. Common considerations include glass transition temperature (Tg) and thermal conductivity values, which dictate how well a material can endure heat and transfer it away from critical areas. For instance, selecting laminates with higher Tg prevents softening under thermal stress, while improved conductivity aids in heat spreading.

Engineers should also evaluate the coefficient of thermal expansion (CTE) to minimize mismatches between layers, reducing the risk of warping or cracking. Adhering to industry standards like IPC-4101C, which specifies laminate material requirements, helps in selecting appropriate substrates for high power applications. Careful material choice directly impacts the board’s ability to manage thermal loads effectively, forming the basis for reliable performance in demanding conditions.

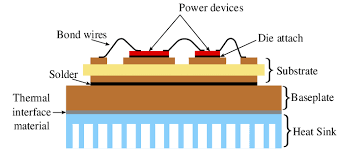

Heat Sink Integration in PCB Design

Incorporating heat sinks into PCB design is a widely adopted method for dissipating heat in high power systems. A heat sink provides a large surface area to transfer thermal energy from hot components to the surrounding environment, often through convection. In multilayer boards, heat sinks are typically mounted on or near high power components to absorb and disperse heat efficiently. Design considerations include the heat sink’s material, usually aluminum or copper due to their high thermal conductivity, and its geometry, which influences airflow and cooling efficiency.

Positioning is critical; heat sinks should be placed to avoid interfering with other components while maximizing exposure to cooling air. Thermal interface materials (TIMs) are often used between the component and heat sink to enhance heat transfer by reducing contact resistance. Engineers must ensure compliance with standards like IPC-7351B for surface mount design to achieve proper alignment and attachment. Effective heat sink PCB design not only lowers component temperatures but also contributes to overall system stability in high power applications.

Utilizing Thermal Vias for Enhanced Heat Dissipation

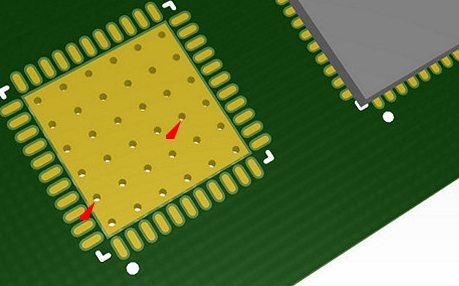

Thermal vias play a pivotal role in high power PCB thermal management by providing low resistance paths for heat to travel from hot spots to cooler areas, often to a heat sink or outer layers. These are small, plated through holes strategically placed near heat generating components in multilayer boards. By connecting inner copper layers to external surfaces, thermal vias facilitate efficient heat transfer, preventing thermal buildup within the board.

Design guidelines, as outlined in IPC-2221B for generic PCB design, recommend optimizing via density and placement to balance thermal performance with electrical integrity. A higher number of vias can improve heat dissipation, but excessive use may compromise structural strength or signal routing. Engineers often arrange thermal vias in arrays under high power components to maximize effectiveness. This approach, when combined with proper copper thickness, significantly enhances cooling in dense multilayer designs, ensuring temperatures remain within acceptable limits.

Advanced Cooling Techniques for High-Power PCBs

Beyond heat sinks and thermal vias, several advanced cooling techniques can be employed to manage heat in high power multilayer PCBs. Forced air cooling, using fans or blowers, directs airflow over critical areas to enhance convective heat transfer. This method is effective for systems with constrained natural convection but requires careful consideration of noise and power consumption. Liquid cooling, though less common in PCB applications, offers superior heat removal for extremely high power designs by circulating coolant through channels or pipes near the board.

Another technique involves embedding metal cores or heat spreading layers within the PCB structure, as per guidelines in IPC-6013D for flexible and rigid flex boards, to distribute heat evenly across layers. These cooling techniques for PCBs must be tailored to specific application needs, considering factors like space constraints and environmental conditions. Combining multiple methods often yields the best results, providing robust thermal management for complex, high power systems.

Best Practices for Thermal Management Design

Implementing effective thermal management in high power multilayer PCBs requires adherence to best practices during design and layout phases. First, prioritize component placement by positioning high power elements near board edges or heat sinks to facilitate heat dissipation. Minimize thermal coupling by spacing heat generating components apart, reducing localized hot spots. Use simulation tools to predict thermal behavior and identify potential issues before fabrication, ensuring designs meet performance expectations.

Incorporate adequate copper planes in inner layers to act as heat spreaders, enhancing overall thermal conductivity. Follow standards like IPC-A-600K for acceptability of printed boards to maintain quality in thermal via and copper layer implementation. Regularly review layer stackup to optimize heat paths while maintaining signal integrity. These practices, grounded in engineering principles, help create robust designs capable of withstanding thermal challenges in high power applications.

Conclusion

Managing heat in high power multilayer PCB designs is a multifaceted challenge that demands careful consideration of materials, design elements, and cooling strategies. From selecting appropriate PCB materials for high temperature tolerance to integrating heat sinks and thermal vias, each aspect plays a vital role in maintaining system reliability. Advanced cooling techniques further enhance thermal performance, addressing the needs of demanding applications. By adhering to industry standards and best practices, engineers can mitigate thermal risks, ensuring optimal operation and longevity of multilayer boards. A proactive approach to high power PCB thermal management ultimately safeguards performance and prevents costly failures in critical electronic systems.

FAQs

Q1: How do thermal vias improve high power PCB thermal management?

A1: Thermal vias create direct paths for heat to move from internal layers to external surfaces or heat sinks in high power PCBs. They reduce thermal resistance, preventing heat buildup near critical components. Properly placed via arrays, as per industry design standards, enhance dissipation efficiency. This ensures components operate within safe temperature ranges, extending system reliability.

Q2: What PCB material is best for high temperature applications?

A2: For high temperature environments, PCB materials with high glass transition temperatures (Tg) and good thermal conductivity are preferred. These properties prevent material degradation and improve heat spreading. Standards like IPC-4101C guide material selection to match application needs. Engineers must balance thermal performance with other factors like cost and electrical properties.

Q3: Which cooling techniques are most effective for high power PCBs?

A3: Cooling techniques for PCBs vary based on design needs. Heat sinks and forced air cooling are common for moderate heat loads, while liquid cooling suits extreme cases. Embedding metal cores also aids heat distribution. Combining methods often yields optimal results, ensuring components stay cool under high power conditions.

Q4: Why is heat sink PCB design critical for multilayer boards?

A4: Heat sink PCB design is vital in multilayer boards to manage heat from densely packed, high power components. Heat sinks absorb and dissipate thermal energy, preventing temperature spikes that could damage parts. Proper integration, following standards like IPC-7351B, ensures efficient cooling, maintaining performance and reliability in complex systems.

References

IPC-4101C — Specification for Base Materials for Rigid and Multilayer Printed Boards. IPC, 2010.

IPC-2221B — Generic Standard on Printed Board Design. IPC, 2012.

IPC-7351B — Generic Requirements for Surface Mount Design and Land Pattern Standard. IPC, 2010.

IPC-6013D — Qualification and Performance Specification for Flexible and Rigid-Flex Printed Boards. IPC, 2017.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.