Introduction

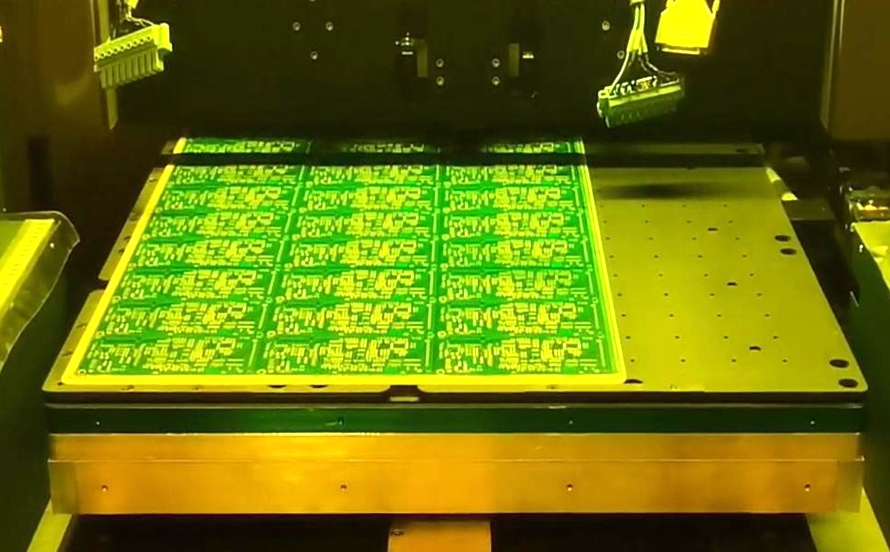

In the realm of circuit board design, the choice of solder mask finish plays a significant role in both aesthetics and functionality. As a PCB designer, understanding the differences between gloss solder masks and matte finishes is crucial for meeting project requirements. This decision impacts surface cosmetics, durability, and even manufacturing outcomes. Solder mask standards guide these choices to ensure reliability and performance.

This article explores the key distinctions between gloss finish boards and matte alternatives, providing technical insights and practical guidance for engineers. By delving into their properties, applications, and alignment with industry standards, you will gain the knowledge needed to make informed decisions for your next design.

What Are Solder Mask Finishes and Why Do They Matter

Solder mask finishes refer to the protective coating applied over the copper traces of a printed circuit board. This layer insulates the traces, prevents oxidation, and avoids unintended solder bridges during assembly. Beyond functionality, the finish type, whether gloss or matte, influences the board’s visual appeal and surface characteristics.

Gloss solder masks offer a shiny, reflective appearance, while matte finishes provide a non-reflective, subdued look. Both serve the same protective purpose but differ in surface cosmetics and interaction with environmental factors. For PCB designers, selecting the right finish ensures compatibility with assembly processes and meets client expectations for appearance. Adhering to solder mask standards also guarantees consistent quality and performance in circuit board design.

Suggested Reading: Understanding Solder Mask: A Beginner's Guide to PCB Protection

Technical Differences Between Gloss and Matte Solder Mask Finishes

Understanding the core properties of gloss and matte finishes is essential for informed decision-making in circuit board design. Both finishes are applied using similar materials, typically liquid photoimageable solder masks, but their surface textures and resulting characteristics vary significantly.

Gloss solder masks create a smooth, reflective surface. This hard shell texture enhances light reflection, making colors appear brighter and more vibrant. The finish is often more resistant to minor abrasions due to its denser surface structure. However, this reflectivity can sometimes interfere with optical inspections, as glare may obscure defects or markings under certain lighting conditions.

Matte finishes, in contrast, have a non-reflective, porous surface. This softer texture absorbs light, resulting in a darker, more muted appearance. While this reduces glare and improves visibility during inspections, the porous nature can make matte boards slightly more susceptible to surface wear or residue buildup. Scratches or handling marks may also be less visible compared to gloss finish boards. Learn more from The Ultimate Guide to different Solder Mask Colors-Benefit of Matte

From a manufacturing standpoint, both finishes follow identical application processes under solder mask standards like IPC-SM-840E. The choice between them does not typically affect production costs or timelines. However, the finish can influence how surface cosmetics are perceived in the final product, impacting client satisfaction or branding requirements.

Impact on Circuit Board Design and Functionality

The choice between gloss and matte finishes extends beyond aesthetics and affects several practical aspects of circuit board design. While neither finish alters the electrical performance of the board, their physical properties can influence specific design considerations.

For designs requiring frequent visual inspections, matte finishes often provide an advantage. Their lack of reflectivity minimizes glare, making it easier to identify surface defects or read silkscreen markings under various lighting conditions. This can be particularly beneficial during quality control processes aligned with standards such as IPC-A-600K, which governs the acceptability of printed boards.

Gloss finish boards, on the other hand, may pose challenges during optical inspections due to their reflective nature. However, their hard surface can offer slightly better resistance to environmental factors like dust or minor impacts during handling. This durability might be preferable for boards expected to undergo rigorous assembly or testing phases.

Another consideration is the interaction with automated optical inspection systems. Matte finishes generally perform better under machine vision due to reduced light scattering. Gloss solder masks, while visually striking, might require adjusted lighting setups to avoid false readings caused by reflections.

Temperature and humidity resistance, critical for reliability, remain unaffected by the finish type as long as the solder mask meets specifications under IPC-SM-840E. Designers must prioritize material quality and application precision over finish type for ensuring long-term performance.

Practical Guidance for Choosing Between Gloss and Matte Finishes

Selecting the appropriate solder mask finish requires balancing aesthetic preferences with practical needs in circuit board design. Below are key factors to guide your decision as a PCB designer.

First, consider the end-use environment. If the board will be exposed to bright lighting or require frequent manual inspection, a matte finish might be more suitable due to its non-reflective properties. This choice aligns with ease of handling and defect detection under quality standards like IPC-A-600K.

Next, evaluate client or branding requirements for surface cosmetics. Gloss solder masks often appeal to projects where visual impact matters, as their shiny appearance can convey a polished, high-quality look. This might be critical for consumer-facing products or prototypes displayed to stakeholders.

Also, assess the assembly and testing conditions. For processes involving automated optical inspection, matte finishes typically offer better compatibility by minimizing glare. If your manufacturing setup adheres to strict inspection protocols, this could streamline quality checks.

Finally, consult solder mask standards to ensure compliance. IPC-SM-840E outlines performance requirements for solder mask coatings, regardless of finish type. Verify that the chosen material and application method meet these criteria to avoid issues like adhesion failure or inconsistent coverage.

Industry Standards and Best Practices for Solder Mask Finishes

Adhering to established solder mask standards is vital for ensuring the reliability and quality of both gloss and matte finishes. The primary guideline for solder mask performance is IPC-SM-840E, which defines qualification and conformance requirements for permanent solder mask coatings. This standard addresses properties like adhesion, resistance to solvents, and thermal stability, applicable to any finish type.

For visual and cosmetic acceptability, IPC-A-600K provides criteria for evaluating printed boards, including solder mask appearance. It specifies acceptable limits for defects such as uneven coating or discoloration, which can affect surface cosmetics in both gloss and matte finishes. Designers and manufacturers must align their processes with these guidelines to meet industry expectations.

Best practices include thorough documentation of finish preferences in design files. Clearly specify whether gloss or matte solder masks are required to avoid miscommunication during fabrication. Additionally, collaborate with fabrication partners to confirm that their application techniques comply with IPC standards, ensuring consistent results.

Regular testing for solder mask integrity, as outlined in IPC-SM-840E, helps identify potential weaknesses early. This includes assessing resistance to environmental stressors, regardless of the chosen finish. By following these practices, designers can achieve optimal performance and aesthetics in their circuit board design.

Conclusion

Choosing between matte finishes and gloss solder masks is a nuanced decision in circuit board design. Each offers distinct advantages in terms of surface cosmetics and practical application. Matte finishes excel in reducing glare and aiding inspections, while gloss finish boards provide a striking visual appeal and minor durability benefits. By understanding their technical differences and aligning choices with solder mask standards like IPC-SM-840E and IPC-A-600K, PCB designers can optimize both functionality and aesthetics. Careful consideration of project needs and industry guidelines ensures that the selected finish enhances the overall quality of the design.

FAQs

Q1: How do gloss solder masks differ from matte finishes in visual inspection?

A1: Gloss solder masks have a reflective surface that can cause glare, potentially complicating visual inspections under certain lighting. Matte finishes, being non-reflective, reduce this issue and make defect detection easier. This aligns with standards like IPC-A-600K for acceptability, ensuring accurate quality assessments during circuit board design and manufacturing processes.

Q2: Do solder mask standards apply equally to gloss and matte finishes?

A2: Yes, solder mask standards such as IPC-SM-840E apply to both gloss and matte finishes without distinction. These standards focus on performance criteria like adhesion and thermal resistance, not surface cosmetics. Regardless of the finish, compliance ensures the solder mask protects the board effectively in any circuit board design.

Q3: What impact does surface cosmetics have on circuit board design choices?

A3: Surface cosmetics influence client perceptions and branding in circuit board design. Gloss finish boards often appear polished and premium, suitable for visible products. Matte finishes offer a subtle look and practical inspection benefits. Balancing aesthetics with functionality is key when selecting a finish for your project.

Q4: Are gloss finish boards more durable than matte finishes in handling?

A4: Gloss finish boards may show slightly better resistance to minor abrasions due to their harder surface. Matte finishes, being softer, can be more prone to surface wear. However, both must meet durability requirements under IPC-SM-840E, ensuring reliability in handling during circuit board design and assembly stages.

References

IPC-SM-840E — Qualification and Conformance Requirements for Permanent Solder Mask and Flexible Cover Materials. IPC, 2010.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.