What Role Does ENIG Play in PCB Longevity?

Understanding the ENIG Surface Finish

Electroless Nickel Immersion Gold (ENIG) is a widely adopted surface finish for printed circuit boards (PCBs), distinguished by its dual-layer structure. It features a layer of nickel deposited over the copper pads, subsequently capped with a thin gold layer. The nickel functions as a protective barrier, preventing copper diffusion, while the gold layer safeguards the nickel from oxidation, ensuring optimal solderability. This combination makes ENIG a preferred choice for applications demanding high reliability across industries such as aerospace, medical, and telecommunications.

How ENIG Influences Board Shelf Life

ENIG significantly contributes to extending the shelf life of PCBs when compared to alternative finishes like Hot Air Solder Leveling (HASL). The gold layer, typically ranging from 2 to 8 microinches in thickness, creates a robust shield against environmental elements that cause oxidation. Nevertheless, even with this protection, the shelf life of ENIG-finished PCBs is not indefinite. Factors such as storage conditions, handling procedures, and the quality of the ENIG application itself can significantly affect how long a board remains usable, typically ranging from six months to over a year under optimal storage.

How Does ENIG Affect a PCB's Usable Life?

The shelf life of a PCB indicates how long it can be stored before its solderability or overall performance begins to decline. For boards finished with ENIG, this duration is influenced by the protective qualities of the gold and nickel layers, though it’s not entirely immune to degradation over time.

Oxidation Resistance and Its Limits

The gold layer in ENIG effectively prevents oxidation of the underlying nickel and copper. Unlike some other finishes, such as immersion silver, which can tarnish rapidly, ENIG offers superior resistance to environmental corrosion. However, if the gold layer is inadequately thin (below 2 microinches), nickel can gradually diffuse to the surface, forming oxides that impair solderability.

The Risk of "Black Pad"

A notable concern with ENIG is the phenomenon known as "black pad." This condition arises from improper plating, which leads to corrosion of the nickel layer during the gold immersion process. Even if a board is within its specified shelf life, this defect can compromise the reliability of solder joints.

Under ideal circumstances, ENIG PCBs generally retain their solderability for six to twelve months. Some boards may remain viable beyond a year if they are stored in a rigorously controlled environment and subjected to a baking process to eliminate moisture before assembly. These considerations emphasize the critical role of proper storage and handling in maximizing the advantages of ENIG and preventing premature degradation.

What Are the Best Storage Practices for ENIG PCBs?

Proper storage conditions are paramount for preserving the shelf life of ENIG-finished PCBs. Exposure to adverse environments can accelerate degradation, even with the protective gold layer. Here are key strategies for storing ENIG boards to ensure long-term solderability and prevent oxidation.

Regulating Temperature and Humidity

Elevated temperatures and high humidity are the primary threats to PCB longevity. Excessive heat can speed up chemical reactions that degrade the surface finish, while moisture can penetrate packaging and lead to corrosion. For ENIG PCBs, aim for these specific conditions:

● Temperature: Maintain a stable temperature range of 15°C to 25°C (59°F to 77°F). Avoid significant fluctuations that could induce condensation.

● Humidity: Keep relative humidity below 50%, ideally between 30% and 40%. Utilize dehumidifiers or climate-controlled storage facilities as needed.

Storing boards in a nitrogen cabinet can further minimize exposure to moisture and oxygen, substantially extending their shelf life.

Essential Packaging and Environmental Controls

Appropriate packaging serves as the initial defense against environmental contaminants. Vacuum-sealed bags, paired with desiccant packs, are highly effective for ENIG PCBs. These bags prevent moisture intrusion and protect against dust or airborne pollutants that could compromise the surface finish. It’s important to ensure packaging integrity and reseal it promptly after any inspection or handling.

Furthermore, prolonged exposure to light, especially UV light, can degrade certain PCB materials over time. Store boards in a dark or shaded area to mitigate this risk. Keep them away from sources of chemical fumes, sulfur compounds, or other contaminants that could react with the surface finish, even if packaged.

Monitoring Storage Duration and Revalidation

Even with ideal conditions, ENIG PCBs have a finite shelf life. It is crucial to mark the manufacturing or receipt date on the packaging and meticulously track storage duration. If boards approach or exceed 12 months in storage, conducting solderability testing before use is recommended. Baking the boards at 120°C (248°F) for 2–4 hours can effectively remove absorbed moisture, potentially restoring usability if no significant oxidation has occurred.

What Strategies Prevent ENIG Oxidation?

While the gold layer in ENIG offers excellent resistance to oxidation, it is not entirely infallible. Over time, or under suboptimal conditions, oxidation of the underlying nickel layer can occur if the gold is too thin or if plating defects are present.

Ensuring Quality Plating and Limiting Air Exposure

To minimize oxidation risk, it is essential to collaborate with a reputable manufacturer to guarantee that the ENIG process adheres to industry standards, such as IPC-4552, which specifies gold thickness and plating quality to avert issues like black pad. Additionally, limit the duration boards are exposed to air during storage and handling. If possible, utilize nitrogen-purged environments for long-term storage.

Regular Inspections

Periodically inspect stored boards for any signs of discoloration or tarnishing, which could indicate oxidation or plating defects. If such issues are detected, it is advisable to consult with your manufacturer before proceeding with assembly. By focusing on these strategies, you can significantly reduce the risk of oxidation and preserve the integrity of your ENIG-finished PCBs.

Suggested Reading: Troubleshooting ENIG: Resolving Common Solderability Issues on PCBs

What to Expect Regarding ENIG Solderability Post-Storage?

Solderability is a critical determinant of whether a stored PCB remains usable. ENIG is renowned for providing excellent solderability due to the gold layer’s compatibility with various soldering processes, including lead-free options. However, after prolonged storage, certain challenges may arise.

Addressing Moisture Absorption and Nickel Diffusion

PCBs can absorb moisture over time, especially in humid environments, which can lead to poor solder wetting during assembly. Baking the boards prior to soldering, as previously mentioned, can alleviate this problem. Moreover, if the gold layer is too thin or compromised, nickel may diffuse to the surface, forming oxides that impede solderability. This issue is more likely after 12 months of storage or in boards with substandard plating.

The Importance of Solderability Testing

If there is any uncertainty about a board’s condition after storage, performing a solderability test according to IPC-J-STD-003 standards is crucial. This involves applying flux and solder to test pads and meticulously inspecting for proper wetting and joint formation. In many instances, ENIG boards stored for over a year can still be utilized if they pass solderability tests and exhibit no visible signs of degradation. The key to achieving this outcome lies in maintaining proper storage conditions.

What Are the Key Handling Guidelines for ENIG PCBs?

Handling practices are as crucial as storage conditions for preserving the shelf life and performance of ENIG PCBs. Improper handling can introduce contaminants or cause physical damage that compromises the surface finish.

Using Protective Gear and Minimizing Physical Contact

Always wear clean, lint-free gloves when handling ENIG PCBs. Skin oils, sweat, and dirt from bare hands can contaminate the gold surface, leading to solderability issues. Additionally, utilize ESD (electrostatic discharge) wrist straps to prevent static damage to sensitive components or traces. Handle boards by their edges to avoid touching the gold-plated pads. Even with gloves, excessive contact can transfer contaminants or cause micro-scratches that affect the finish.

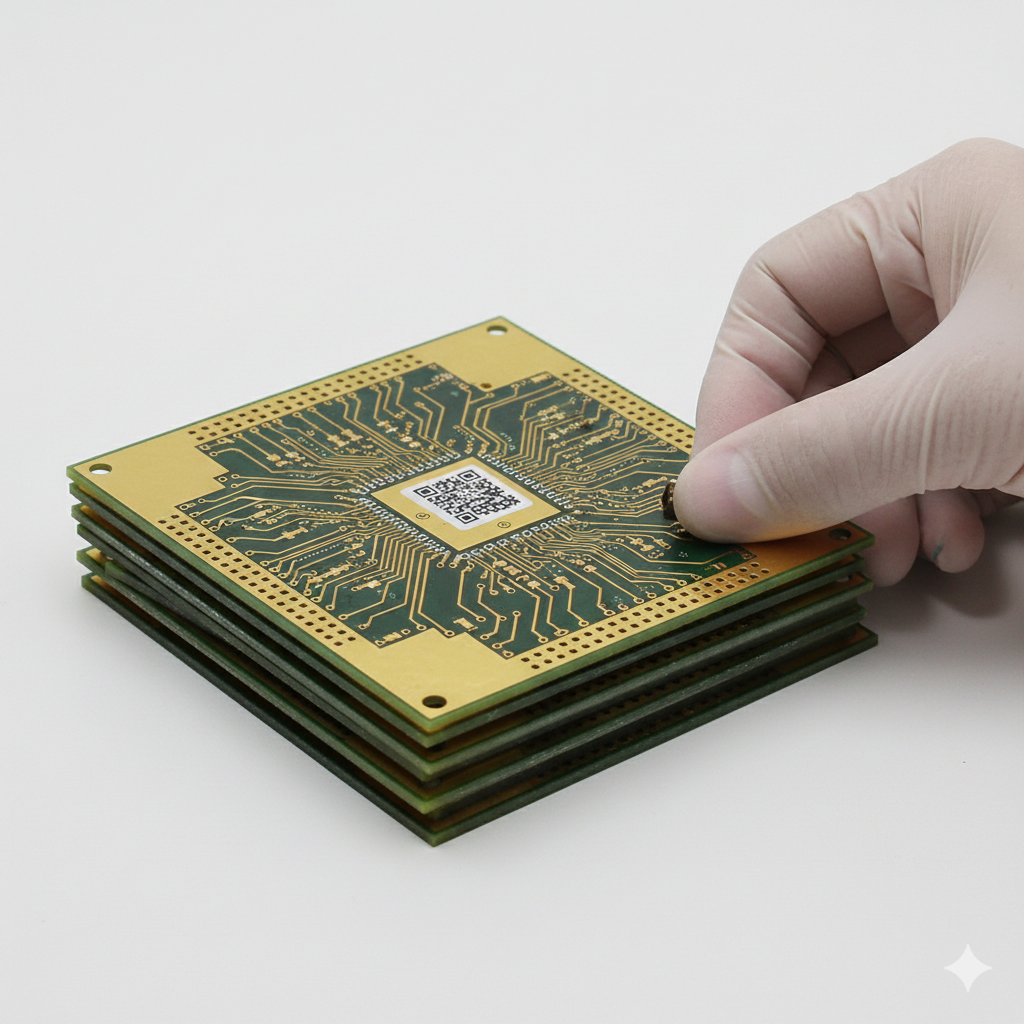

Preventing Damage During Storage and in the Workspace

Never stack bare PCBs directly on top of each other. Use protective separators or foam sheets between boards to prevent scratching or mechanical damage to the ENIG surface. Furthermore, perform all handling and inspection in a clean, dust-free workspace. Airborne particles can settle on the board and interfere with soldering or cause long-term degradation if not removed.

Why Is ENIG a Preferred Choice for Long-Term Reliability?

ENIG stands out as a premier choice for PCB surface finishes due to its balanced combination of durability, solderability, and corrosion resistance. While it may entail a higher initial cost compared to other finishes, its extended shelf life and reduced oxidation risk make it a cost-effective solution for applications where reliability is paramount. By adhering to the storage and handling best practices outlined, the benefits of ENIG can be maximized, ensuring these types of PCBs perform as expected, even after extended storage periods.

Conclusion

The influence of ENIG on PCB shelf life is substantial, providing a robust method for protecting copper pads and maintaining solderability over time. With a typical shelf life of six to twelve months, and potentially longer under optimal conditions, ENIG-finished boards offer a reliable choice for numerous industries. However, achieving this longevity demands meticulous attention to storage conditions, oxidation prevention, and handling practices. By controlling temperature and humidity, using appropriate packaging, minimizing contaminant exposure, and following stringent handling guidelines, the quality of ENIG PCBs can be preserved, ensuring successful assembly even after months in storage. Implementing these best practices not only extends the usable life of your boards but also mitigates the risk of costly rework or failures in the field.