Introduction

Radio Frequency (RF) PCB design for automotive applications presents unique challenges due to the demanding conditions of the automotive environment. From extreme temperature fluctuations to constant vibration and stringent reliability requirements, automotive PCBs must perform flawlessly to ensure safety and functionality. As vehicles integrate advanced systems like ADAS (Advanced Driver Assistance Systems), infotainment, and V2X (Vehicle-to-Everything) communication, the role of RF PCB automotive design becomes critical. This article explores the principles of designing RF PCBs for automotive use, focusing on temperature range, vibration resistance, and reliability. It provides practical insights for engineers to meet industry standards and ensure robust performance in harsh environments. Whether you are optimizing for RF PCB temperature range automotive needs or addressing RF PCB vibration automotive concerns, this guide offers actionable solutions.

What Is RF PCB Design for Automotive Applications and Why It Matters

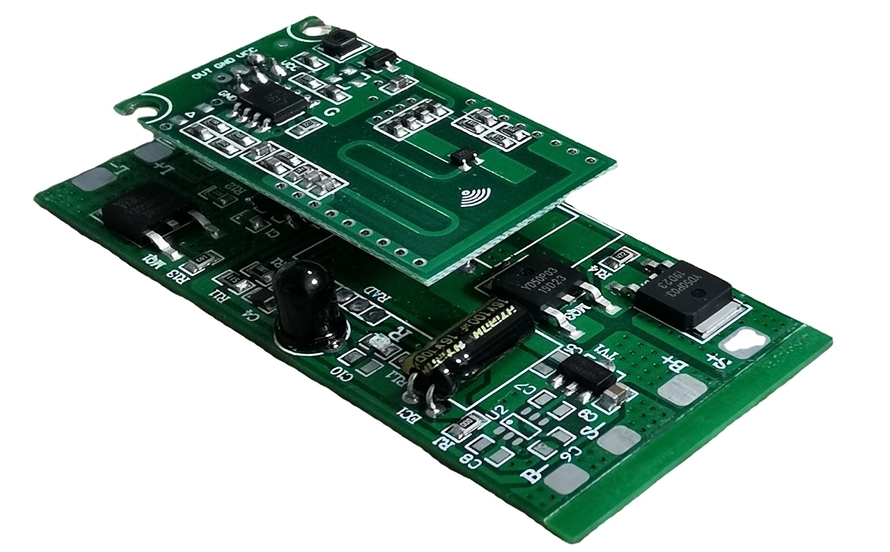

RF PCB design involves creating printed circuit boards that handle high-frequency signals, typically in the range of megahertz to gigahertz. In automotive applications, these boards are integral to systems such as radar, GPS, wireless communication, and sensor networks. The importance of RF PCB automotive design lies in its direct impact on vehicle safety, performance, and connectivity. A poorly designed RF PCB can lead to signal loss, interference, or complete system failure, which is unacceptable in critical automotive functions.

Automotive environments are far more challenging than typical consumer electronics settings. RF PCBs must operate under wide temperature swings, endure constant mechanical stress from vibrations, and maintain long-term reliability. Meeting these demands ensures that systems like collision avoidance radar or emergency communication remain functional. For engineers, understanding RF PCB reliability automotive standards is essential to delivering solutions that withstand harsh conditions without compromising performance.

Technical Principles of RF PCB Design for Harsh Automotive Environments

Temperature Range Challenges and Material Selection

Automotive RF PCBs often face temperature extremes ranging from sub-zero conditions to high heat near engines or in direct sunlight. According to industry standards like those outlined in JEDEC J-STD-020E, components and materials must be tested for thermal stress to ensure functionality across specified ranges. The thermal expansion mismatch between materials can cause mechanical stress, leading to cracks or delamination in the PCB structure.

To address RF PCB temperature range automotive challenges, selecting appropriate substrate materials is vital. High-frequency laminates with low dielectric loss and stable thermal properties are preferred. Additionally, ensuring that solder joints and components comply with thermal cycling tests, as per IPC-9701, helps predict long-term performance under temperature stress. Engineers must also consider thermal vias and heat dissipation techniques to manage heat buildup in high-power RF circuits.

Vibration and Mechanical Stress Resistance

Vibration is another critical factor in the design of automotive electronics PCB. Vehicles are subject to continuous mechanical shocks from road conditions, engine operation, and other sources. These vibrations can cause fatigue in solder joints, component displacement, or trace cracking, impacting RF PCB vibration automotive performance. Standards such as IPC-6012E specify requirements for structural integrity under mechanical stress, providing guidelines for testing and validation.

The design must incorporate secure mounting techniques and robust trace layouts to minimize the risk of failure. Using thicker copper layers and reinforcing critical areas with additional vias can enhance mechanical stability. Components should be chosen based on their ability to withstand vibration, often validated through tests aligned with ISO 16750-3, which covers environmental conditions for automotive electronics.

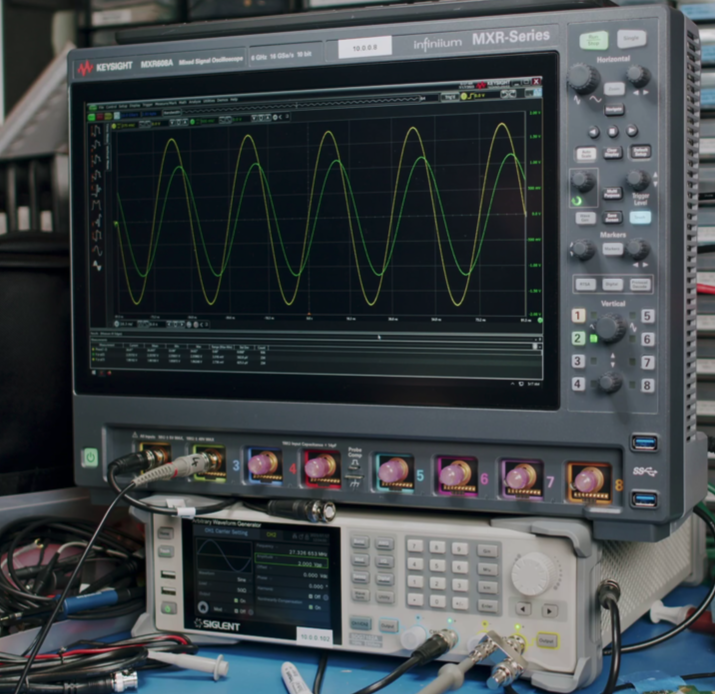

Signal Integrity in High-Frequency Applications

RF PCBs in automotive systems handle high-frequency signals where maintaining signal integrity is paramount. Harsh environments can introduce noise, electromagnetic interference (EMI), and signal degradation. Proper impedance matching, controlled trace widths, and minimized parasitic effects are essential to preserve signal quality. Ground planes must be carefully designed to reduce EMI, adhering to principles outlined in IPC-2221B for high-speed design.

Environmental factors like humidity and temperature can also alter dielectric properties, affecting signal performance. Engineers must account for these variables during the design phase by selecting materials with stable electrical characteristics and incorporating shielding techniques to protect sensitive RF circuits from external interference.

Practical Solutions for RF PCB Design in Automotive Applications

Design Strategies for Temperature Resilience

To ensure RF PCB temperature range automotive performance, engineers should prioritize thermal management in their designs. Incorporating thermal vias near high-power components helps dissipate heat efficiently. Using substrates with high glass transition temperatures (Tg) ensures stability under thermal stress. Compliance with IPC-A-600K for material acceptability can guide the selection of laminates and prepregs that meet thermal requirements.

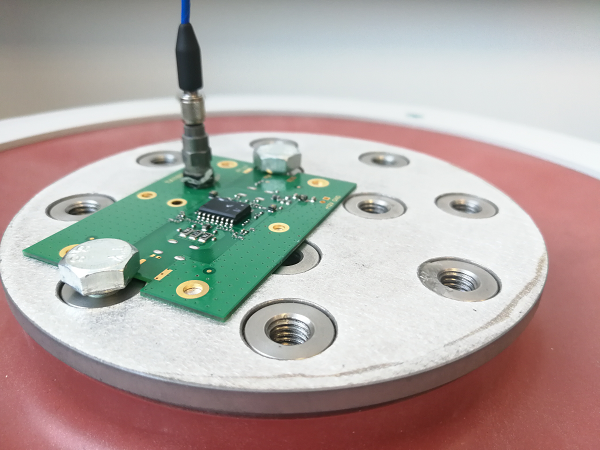

Simulation tools aligned with industry standards can predict thermal behavior, allowing designers to identify hotspots before prototyping. Additionally, placing temperature-sensitive components away from heat sources and ensuring adequate airflow in the enclosure can mitigate thermal risks. Regular testing under conditions specified in JEDEC J-STD-020E ensures that the design withstands thermal cycling without failure.

Mitigating Vibration Effects

Addressing RF PCB vibration automotive challenges requires a multi-faceted approach. Securely anchoring the PCB to the chassis with vibration-dampening mounts reduces mechanical stress. Using flexible or rigid-flex designs in areas prone to high vibration can prevent cracking. Adhering to IPC-6012E standards for structural performance ensures that the board withstands mechanical shocks during testing.

Component placement should avoid high-stress areas, and larger components may require additional mechanical support like adhesives or brackets. Vibration testing, as per ISO 16750-3, validates the design by simulating real-world conditions. Engineers should also consider using heavier copper weights for traces to enhance durability against mechanical fatigue.

Ensuring Long-Term Reliability

RF PCB reliability automotive performance hinges on rigorous design and testing protocols. Following IPC-9701 guidelines for thermal and mechanical stress testing helps predict failure modes over the PCB's lifespan. Designing with redundancy in critical RF paths can prevent system failure if a single component or trace is compromised.

Environmental testing for humidity, salt spray, and dust exposure, as outlined in ISO 16750-4, ensures the fast turn PCB can endure varied conditions. Using conformal coatings protects against moisture and contaminants, extending reliability. Regular design reviews and simulations based on real-world data improve the chances of meeting stringent automotive requirements.

Standards Compliance for Automotive RF PCBs

Compliance with industry standards is non-negotiable in automotive RF PCB design. ISO 26262 addresses functional safety for automotive electronics, providing a framework for risk assessment and mitigation. JEDEC standards, such as J-STD-020E, ensure components handle thermal and moisture stress. IPC standards like IPC-6012E and IPC-A-600K cover manufacturing and acceptability criteria, ensuring consistent quality.

Engineers must integrate these standards into every design phase, from material selection to final testing. Documentation of compliance with these standards not only validates the design but also builds trust in the system's reliability for automotive applications.

Suggested Reading: Optimizing RF PCB Performance: The Crucial Role of Surface Finish Selection

Insight: Balancing Performance and Cost in RF PCB Design

Achieving optimal RF PCB automotive design often involves balancing performance with cost constraints. High-performance materials and advanced manufacturing processes can significantly increase expenses. Engineers must prioritize critical areas, such as signal integrity in radar systems, while opting for cost-effective solutions in less demanding sections. Using standardized testing protocols from IPC and ISO ensures reliability without unnecessary over-engineering.

Collaboration between design and manufacturing teams can identify cost-saving opportunities, such as optimizing layer counts or simplifying trace layouts without sacrificing performance. Iterative testing and simulation help refine the design, ensuring that RF PCB reliability automotive goals are met within budget limitations.

Conclusion

RF PCB design for automotive applications requires a deep understanding of the harsh environments in which these boards operate. From addressing RF PCB temperature range automotive challenges to ensuring RF PCB vibration automotive resilience, every design decision impacts performance and safety. By focusing on material selection, thermal management, vibration resistance, and adherence to standards like IPC-6012E and ISO 26262, engineers can create robust RF PCBs that meet automotive demands. Prioritizing RF PCB reliability automotive standards ensures that critical systems function without fail, supporting the advancement of safer and smarter vehicles. This guide provides a foundation for tackling the complexities of automotive RF PCB design with confidence.

FAQs

Q1: What are the key challenges in RF PCB automotive design?

A1: RF PCB automotive design faces challenges like extreme temperature variations, constant vibration, and high reliability demands. These boards must operate in harsh conditions without signal loss or failure. Ensuring proper material selection and compliance with standards like IPC-6012E is crucial. Engineers must address thermal stress and mechanical fatigue to maintain performance in critical systems like radar and communication.

Q2: How does temperature affect RF PCB temperature range automotive performance?

A2: Temperature extremes can cause thermal expansion, leading to cracks or delamination in RF PCBs. For automotive applications, boards must function across a wide range as per JEDEC J-STD-020E guidelines. High heat or cold can also alter dielectric properties, impacting signal integrity. Proper material selection and thermal management are essential to mitigate these effects.

Q3: What design techniques improve RF PCB vibration automotive resistance?

A3: To enhance RF PCB vibration automotive resistance, use vibration-dampening mounts and secure anchoring. Opt for thicker copper layers and reinforce critical areas with vias as per IPC-6012E standards. Flexible designs can absorb stress, while strategic component placement avoids high-stress zones. Testing under ISO 16750-3 conditions validates the design against real-world vibrations.

Q4: Why is RF PCB reliability automotive critical for vehicle safety?

A4: RF PCB reliability automotive performance directly impacts vehicle safety systems like ADAS and emergency communication. Failures in RF circuits can disrupt radar or GPS, risking accidents. Adhering to ISO 26262 for functional safety ensures consistent operation. Reliable designs prevent signal loss, maintaining the integrity of critical automotive functions under harsh conditions.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

IPC-9701 — Performance Test Methods and Qualification Requirements for Surface Mount Solder Attachments. IPC, 2002.

IPC-2221B — Generic Standard on Printed Board Design. IPC, 2012.

JEDEC J-STD-020E — Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices. JEDEC, 2014.

ISO 26262:2018 — Road Vehicles – Functional Safety. ISO, 2018.

ISO 16750-3:2012 — Road Vehicles – Environmental Conditions and Testing for Electrical and Electronic Equipment – Mechanical Loads. ISO, 2012.

ISO 16750-4:2010 — Road Vehicles – Environmental Conditions and Testing for Electrical and Electronic Equipment – Climatic Loads. ISO, 2010.