Introduction

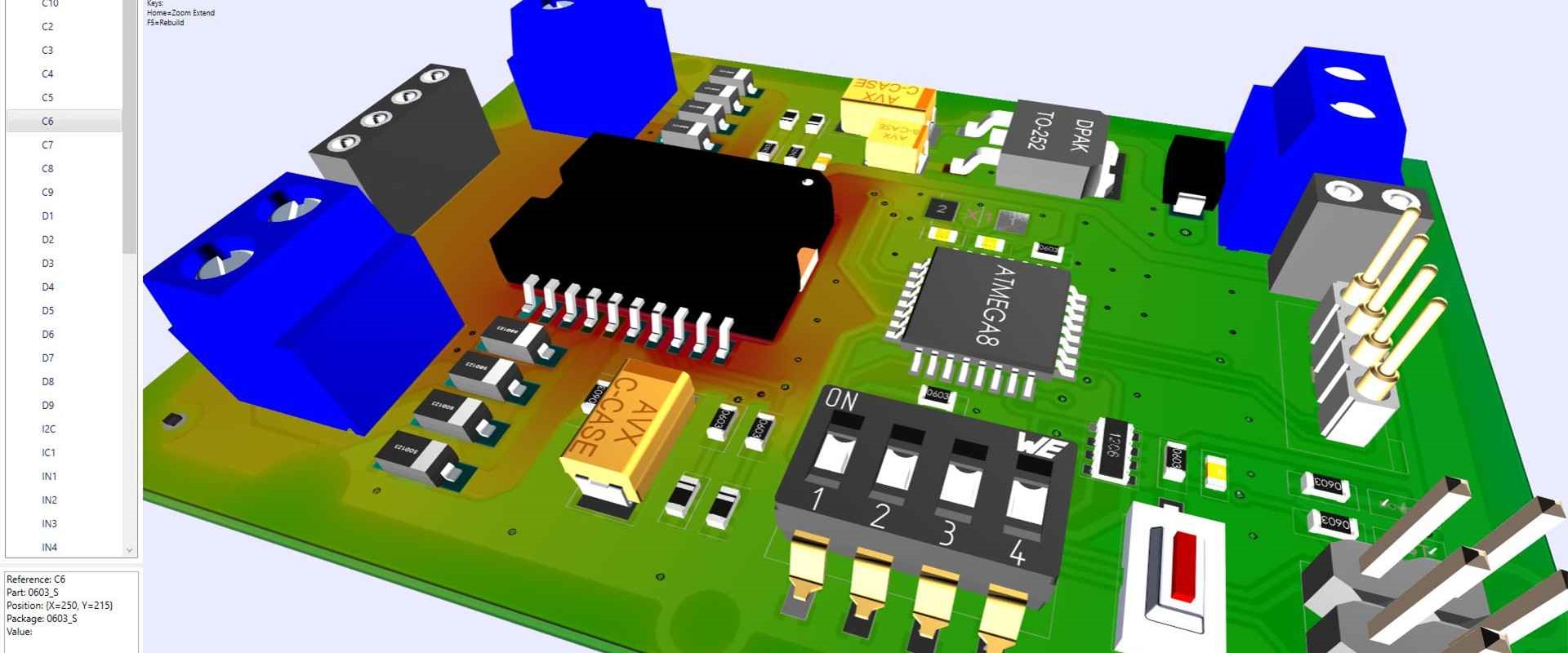

Smart grids represent a transformative approach to power distribution, integrating advanced communication and control technologies to optimize energy efficiency and reliability. At the heart of these systems lie printed circuit boards (PCBs) that must withstand demanding conditions such as high frequencies, elevated temperatures, and significant power loads. Selecting the right substrate materials for smart grid applications is critical to ensure performance, longevity, and safety. This article explores high-frequency PCB materials for smart grids, high-temperature PCB materials for smart grids, low-loss PCB materials for smart grids, ceramic PCBs for smart grids, and metal core PCBs for smart grid thermal management. Aimed at electrical engineers, the content provides technical insights into material properties, design considerations, and industry standards to guide substrate selection for optimal outcomes in smart grid infrastructure.

Why Smart Grid PCB Materials Matter

Smart grids rely on PCBs to manage real-time data transmission, power conversion, and system monitoring. These boards operate in environments with high electrical stress, thermal fluctuations, and signal integrity challenges. Poor material choices can lead to signal loss, overheating, or premature failure, disrupting grid reliability. High-frequency PCB materials for smart grids are essential for maintaining signal clarity in communication modules. Similarly, high-temperature PCB materials for smart grids prevent degradation in hot outdoor enclosures. Low-loss PCB materials for smart grids reduce energy waste, while ceramic PCBs for smart grids offer durability under stress. Metal core PCBs for smart grid thermal management dissipate heat effectively. Choosing substrates aligned with these needs ensures system stability and supports the grid's role in modern energy networks.

Technical Principles of PCB Materials for Smart Grids

High-Frequency Performance

Smart grid systems often handle high-speed data for monitoring and control, requiring substrates with excellent dielectric properties. Materials with low dielectric constant and low dissipation factor are vital to minimize signal loss and maintain integrity at high frequencies. These high-frequency PCB materials for smart grids enable efficient operation of communication circuits, ensuring accurate data transfer between grid components. The substrate must also resist impedance variations to avoid signal distortion.

High-Temperature Resistance

Outdoor smart grid equipment faces extreme heat, especially in regions with harsh climates. High-temperature PCB materials for smart grids must have a high glass transition temperature to prevent softening or delamination during thermal stress. Such materials maintain mechanical stability and electrical performance, protecting circuits from failure in power conversion units exposed to elevated temperatures.

Low-Loss Characteristics

Energy efficiency is a core goal of smart grids, making low-loss PCB materials for smart grids critical. These substrates reduce dielectric losses, ensuring minimal energy dissipation during power transmission or conversion. This property is especially important in high-power applications where heat generation must be controlled to avoid system inefficiencies.

Ceramic Substrates for Durability

Ceramic PCBs for smart grids provide superior thermal conductivity and mechanical strength, ideal for compact, high-density designs. These materials resist thermal expansion mismatches, reducing the risk of cracking under temperature cycles. Their ability to handle high voltages also suits them for power electronics in grid systems.

Metal Core for Thermal Management

Effective heat dissipation is a priority in smart grid hardware due to high current loads. Metal core PCBs for smart grid thermal management use a metallic base, typically aluminum or copper, to conduct heat away from critical components. This prevents hotspots and extends the lifespan of power management circuits.

Related Reading: Aluminum PCBs: Thermal Management for High Power Electronics

Key Material Properties and Standards

Selecting PCB materials for smart grids involves evaluating specific properties against recognized benchmarks. Below is a summary of critical characteristics and relevant industry standards for material performance.

Dielectric Constant: Affects signal speed in high-frequency applications. Relevant Standard: IPC-6012E.

Thermal Conductivity: Ensures heat dissipation in power modules. Relevant Standard: JEDEC J-STD-020E.

Glass Transition Temperature: Maintains stability under heat stress. Relevant Standard: IPC-A-600K.

Coefficient of Thermal Expansion: Reduces mechanical stress from temperature changes. Relevant Standard: ASTM D696.

Standards such as IPC-6012E guide the qualification of rigid PCBs for electrical and mechanical performance, while JEDEC J-STD-020E addresses moisture and thermal stress during assembly. IPC-A-600K sets acceptability criteria for board quality, ensuring reliability in demanding conditions. ASTM D696 provides methods to measure thermal expansion, critical for material compatibility in smart grid environments.

Related Reading: Beyond FR 4: Selecting the Right Substrate for Your Embedded Component PCB

Practical Solutions for Substrate Selection

Matching Materials to Application Needs

Engineers must align substrate properties with specific smart grid functions. For communication modules, prioritize high-frequency PCB materials for smart grids with low dielectric loss. In power inverters, opt for high-temperature PCB materials for smart grids to handle thermal loads. Low-loss PCB materials for smart grids suit energy-efficient designs, reducing operational costs. Ceramic PCBs for smart grids work well in high-voltage sensors, while metal core PCBs for smart grid thermal management are ideal for heat-intensive converters.

Design Considerations for Reliability

Beyond material selection, design plays a role in performance. Ensure proper layer stackup to control impedance in high-frequency circuits. Use thermal vias with metal core PCBs to enhance heat transfer. Minimize trace lengths to reduce signal loss with low-loss PCB materials for smart grids. Adhering to guidelines in IPC-6012E helps maintain fabrication quality, preventing defects that compromise reliability.

Testing and Validation

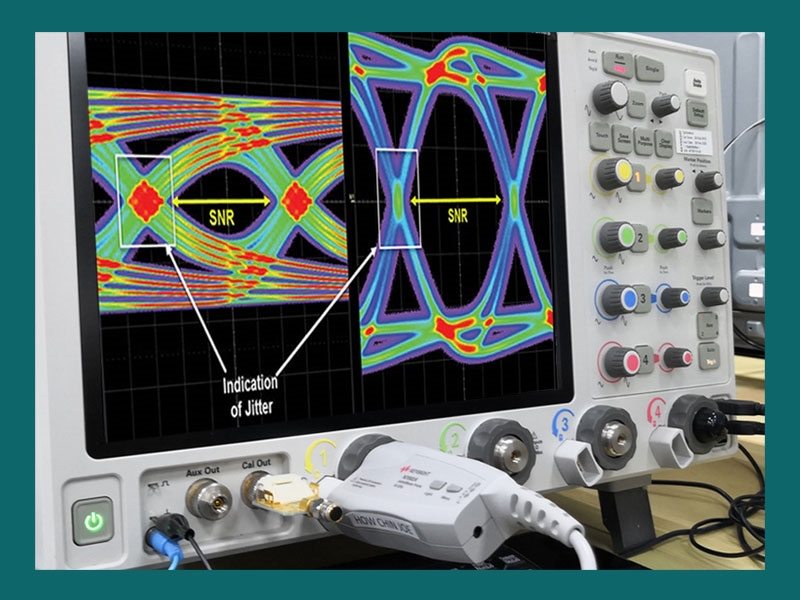

Validate material choices through rigorous testing. Conduct thermal cycling per JEDEC J-STD-020E to assess high-temperature PCB materials for smart grids under stress. Measure signal integrity for high-frequency PCB materials using industry-standard equipment. Verify board quality against IPC-A-600K to ensure compliance with acceptability criteria. These steps confirm that substrates meet smart grid demands before deployment.

Challenges in Smart Grid PCB Material Selection

Material selection is not without challenges. High-frequency PCB materials for smart grids often cost more, impacting project budgets. High-temperature PCB materials for smart grids may have limited availability for specific designs. Ceramic PCBs for smart grids can be brittle, requiring careful handling during assembly. Metal core PCBs for smart grid thermal management add weight, which may not suit lightweight applications. Engineers must balance these trade-offs, using standards like IPC-6012E to guide decisions on performance versus practicality.

Conclusion

Selecting the right PCB materials for smart grid applications is a foundational step in ensuring system reliability and efficiency. High-frequency PCB materials for smart grids maintain signal integrity in communication systems. High-temperature PCB materials for smart grids withstand harsh environments, while low-loss PCB materials for smart grids enhance energy efficiency. Ceramic PCBs for smart grids offer durability for high-voltage needs, and metal core PCBs for smart grid thermal management address heat dissipation challenges. By adhering to standards such as IPC-6012E, JEDEC J-STD-020E, IPC-A-600K, and ASTM D696, engineers can make informed choices that optimize performance. Careful consideration of material properties and application requirements leads to robust designs capable of supporting the future of energy infrastructure.

FAQs

Q1: What are the best high-frequency PCB materials for smart grids?

A1: High-frequency PCB materials for smart grids should have a low dielectric constant and minimal dissipation factor to ensure signal integrity. These materials support fast data transfer in communication modules. Testing per IPC-6012E ensures they meet performance criteria for rigid boards in demanding grid applications.

Q2: How do high-temperature PCB materials for smart grids improve reliability?

A2: High-temperature PCB materials for smart grids resist thermal degradation with a high glass transition temperature. They prevent softening or failure in hot environments like outdoor enclosures. Compliance with IPC-A-600K ensures quality, reducing risks of delamination during thermal stress in power systems.

Q3: Why use metal core PCBs for smart grid thermal management?

A3: Metal core PCBs for smart grid thermal management efficiently dissipate heat from high-power components using a metallic base. This prevents overheating in converters and extends circuit life. Following JEDEC J-STD-020E during assembly ensures they withstand thermal and moisture stress reliably.

Q4: Are ceramic PCBs for smart grids suitable for high-voltage applications?

A4: Ceramic PCBs for smart grids excel in high-voltage applications due to their excellent thermal conductivity and mechanical strength. They resist thermal expansion issues and handle electrical stress well. Validation against IPC-6012E confirms their suitability for compact, high-density designs in grid sensors.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

JEDEC J-STD-020E — Moisture/Reflow Sensitivity Classification. JEDEC, 2014.

ASTM D696 — Standard Test Method for Coefficient of Linear Thermal Expansion of Plastics Between -30°C and 30°C with a Vitreous Silica Dilatometer. ASTM, 2016.