Introduction

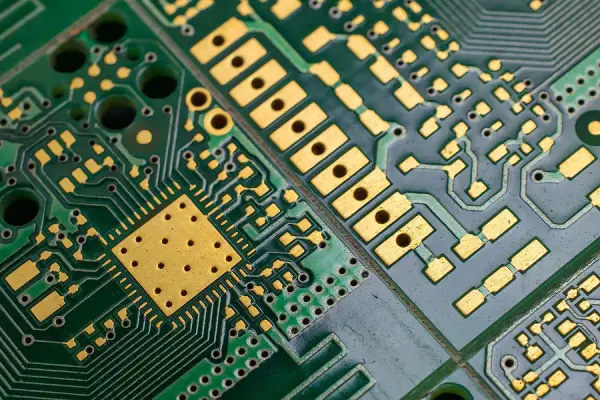

Printed circuit boards form the backbone of railway electronics, controlling critical systems like signaling, communication, and power management. In the harsh environments of railway applications, reliability is paramount. Factors such as temperature fluctuations, vibration, and humidity challenge the durability of these boards. A key element influencing their performance is the surface finish applied to the copper traces. This protective layer affects solderability, corrosion resistance, and long-term functionality. Surface finishes like ENIG, HASL, immersion silver, and OSP each offer unique benefits and limitations for railway PCB corrosion resistance. Understanding their impact is essential for engineers designing electronics for trains and infrastructure. This article explores how these finishes influence reliability and provides insights into selecting the most suitable option for railway applications.

Why PCB Surface Finish Matters in Railway Electronics

Railway electronics operate in demanding conditions. Exposure to moisture, dust, and chemical contaminants can degrade unprotected copper traces, leading to failures. The surface finish acts as a barrier, protecting the board from oxidation and ensuring robust connections during assembly and operation. For railway systems, where downtime can disrupt schedules and compromise safety, selecting the right finish is critical. A poor choice may result in corrosion, reduced solder joint integrity, or electrical shorts over time. Finishes must also comply with industry standards like those set by IPC for performance and durability. In this context, evaluating options such as ENIG surface finish railway PCB or HASL surface finish railway PCB becomes a priority for engineers aiming to balance cost, reliability, and manufacturability.

Technical Principles of PCB Surface Finishes

Surface finishes serve two primary roles: protecting copper from oxidation and providing a solderable surface for component attachment. Each finish has distinct properties that influence its suitability for railway electronics. Below, the mechanisms and characteristics of common finishes are discussed.

Electroless Nickel Immersion Gold (ENIG)

ENIG involves depositing a layer of nickel over copper, followed by a thin gold coating. The nickel acts as a diffusion barrier, while gold prevents oxidation and enhances solderability. This finish excels in corrosion resistance, making it a strong candidate for ENIG surface finish railway PCB applications. It withstands multiple reflow cycles without degrading, which is vital for complex assemblies. However, the process is more expensive and can occasionally suffer from issues like black pad syndrome if not controlled properly.

Hot Air Solder Leveling (HASL)

HASL applies a layer of solder to the copper surface using a hot air leveling process. It is cost-effective and widely used due to its excellent solderability. For HASL surface finish railway PCB designs, it offers decent protection against oxidation. Yet, its uneven surface can pose challenges for fine-pitch components, and it may not provide the same level of corrosion resistance as other finishes in humid or polluted environments typical of railway settings.

Immersion Silver

Immersion silver deposits a thin silver layer directly onto copper. It provides a flat surface ideal for fine-pitch soldering and offers good conductivity. As an immersion silver surface finish railway PCB option, it performs well in terms of solderability. However, silver is prone to tarnishing when exposed to sulfur or chloride environments, which can compromise reliability unless proper storage and handling are ensured.

Organic Solderability Preservative (OSP)

OSP is a water-based organic coating that protects copper from oxidation. It is cost-effective and environmentally friendly, often considered for OSP surface finish railway PCB projects. It provides a flat surface for soldering but offers limited shelf life and weaker corrosion resistance compared to metallic finishes. Repeated thermal cycles can degrade the coating, making it less ideal for harsh railway conditions.

Related Reading: Advanced Surface Finishes: Choosing the Right Option for PCB Mass Production

Impact on Railway PCB Corrosion Resistance

Railway environments expose electronics to moisture, temperature extremes, and contaminants like salt or industrial pollutants. Corrosion of PCB traces or solder joints can lead to signal loss or complete system failure. The choice of surface finish directly affects railway PCB corrosion resistance.

ENIG offers superior protection due to its gold layer, resisting oxidation even in humid conditions. Tests under industry standards, such as those outlined in IPC-4552A, demonstrate its ability to maintain integrity after prolonged exposure to harsh environments. Immersion silver, while initially effective, can degrade in sulfur-rich atmospheres, forming silver sulfide that impairs conductivity. HASL provides moderate resistance but may develop solder voids under thermal stress. OSP, being non-metallic, shows the least resistance to corrosive elements over time, as noted in studies aligned with IPC-4556.

Engineers must weigh these factors against operational conditions. For instance, electronics in coastal railway lines may benefit more from ENIG due to salt exposure, while inland systems might tolerate HASL or OSP for cost savings.

Practical Solutions for Selecting Surface Finishes

Choosing the right surface finish for railway electronics requires balancing performance, cost, and manufacturing constraints. Below are actionable guidelines based on industry practices and standards.

Assess Environmental Exposure

Evaluate the specific conditions the PCB will face. Coastal or industrial areas with high humidity or pollutants favor finishes like ENIG for enhanced railway PCB corrosion resistance. For milder environments, HASL or OSP may suffice if budget constraints are a concern.

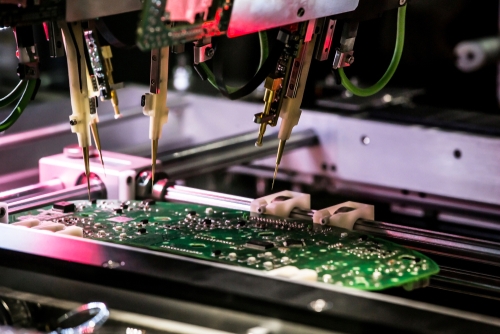

Consider Component and Assembly Needs

Fine-pitch components and high-density designs benefit from flat finishes like immersion silver or ENIG. HASL, with its uneven surface, may lead to alignment issues during assembly. Refer to IPC-7351B for guidelines on land pattern design and finish compatibility.

Prioritize Long-Term Reliability

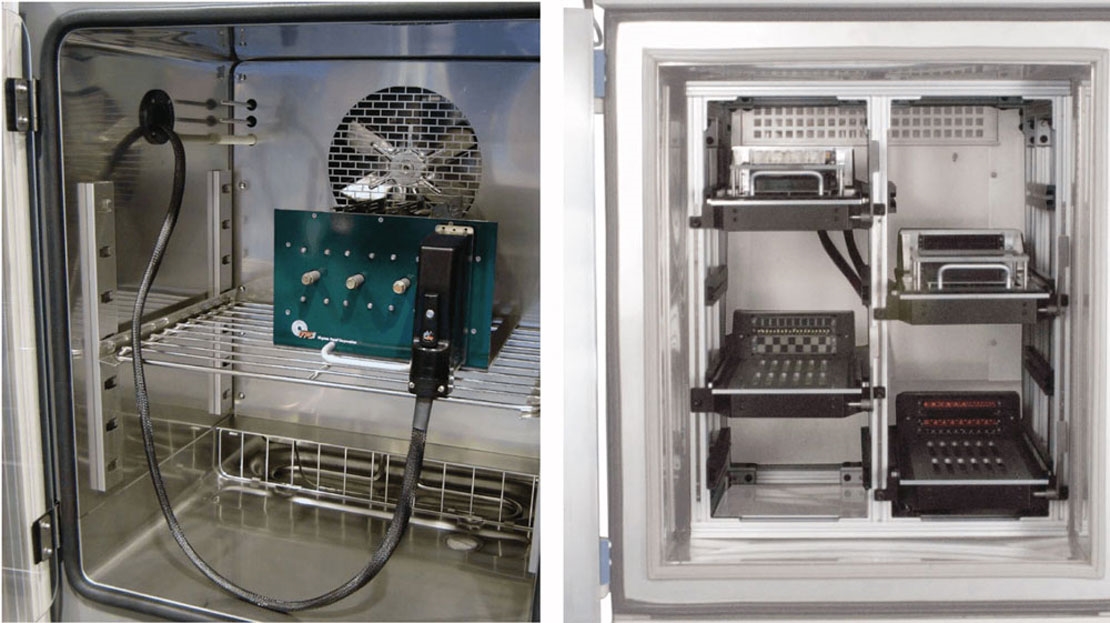

Railway systems often require electronics to function reliably for decades. Finishes must withstand thermal cycling and vibration without degrading. ENIG and immersion silver surface finish railway PCB options typically outperform others in durability tests under IPC-6012E standards.

Evaluate Cost Against Performance

While ENIG offers top-tier protection, its higher cost may not be justified for all projects. HASL remains a practical choice for less critical applications where cost is a primary factor. OSP can be viable for short-term or controlled environments.

Standards and Compliance in Railway PCB Design

Adherence to industry standards ensures that surface finishes meet the reliability demands of railway electronics. IPC-4552A governs ENIG processes, specifying thickness and quality requirements for nickel and gold layers. Similarly, IPC-4554 addresses immersion silver, outlining tarnish resistance and solderability criteria. For HASL, IPC-4553A provides benchmarks for solder coverage and thermal resistance. These standards, when followed, help mitigate risks of corrosion and assembly defects.

Railway applications may also require compliance with broader quality systems like ISO 9001:2015, ensuring consistent manufacturing processes. Vibration and thermal testing, as per IEC 61373, simulate railway conditions to validate finish performance. Engineers should integrate these standards into design and procurement specifications to achieve optimal outcomes.

Related Reading: Troubleshooting and Repairing Common PCB Surface Finish Defects

Conclusion

The surface finish of a printed circuit board plays a pivotal role in the reliability of railway electronics. Options like ENIG surface finish railway PCB provide exceptional corrosion resistance, ideal for harsh environments, while HASL surface finish railway PCB offers a cost-effective alternative for less demanding applications. Immersion silver and OSP surface finish railway PCB choices cater to specific needs like fine-pitch soldering or environmental considerations. By understanding the technical properties and environmental challenges, engineers can make informed decisions to enhance system longevity. Aligning selections with industry standards ensures performance and durability, safeguarding critical railway operations against failures.

FAQs

Q1: How does ENIG surface finish improve railway PCB reliability?

A1: ENIG surface finish enhances railway PCB reliability by offering excellent corrosion resistance through its gold and nickel layers. It protects copper traces from oxidation in humid or polluted environments, common in railway settings. Compliant with IPC-4552A, it ensures durability under thermal stress and multiple reflow cycles. This makes it a preferred choice for critical electronics where long-term performance is essential.

Q2: What are the limitations of HASL surface finish for railway PCB applications?

A2: HASL surface finish for railway PCB applications is cost-effective but has limitations. Its uneven surface can complicate soldering of fine-pitch components, risking assembly defects. While it offers moderate railway PCB corrosion resistance, it may not withstand extreme humidity or chemical exposure as effectively as other finishes. Engineers must assess environmental conditions before opting for HASL in critical systems.

Q3: Is immersion silver surface finish suitable for railway PCB corrosion resistance?

A3: Immersion silver surface finish provides good solderability and a flat surface for railway PCB assembly. However, its corrosion resistance is limited in sulfur or chloride-rich environments, where tarnishing can occur. As per IPC-4554, proper handling and storage are crucial to maintain its integrity. It may suit controlled settings but requires caution in harsh railway conditions.

Q4: When should OSP surface finish be used in railway PCB designs?

A4: OSP surface finish for railway PCB designs is best for cost-sensitive projects in mild environments. It offers a flat, eco-friendly coating for soldering but has limited shelf life and weaker railway PCB corrosion resistance. Under IPC-4556 guidelines, it may degrade with repeated thermal cycles, making it less ideal for extreme conditions. Use it only when exposure risks are minimal.

References

IPC-4552A — Specification for Electroless Nickel/Immersion Gold (ENIG) Plating for Printed Boards. IPC, 2017.

IPC-4553A — Specification for Immersion Silver Plating for Printed Boards. IPC, 2009.

IPC-4554 — Specification for Immersion Tin Plating for Printed Circuit Boards. IPC, 2012.

IPC-4556 — Specification for Organic Solderability Preservative (OSP) for Printed Boards. IPC, 2013.

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-7351B — Generic Requirements for Surface Mount Design and Land Pattern Standard. IPC, 2010.

ISO 9001:2015 — Quality Management Systems. ISO, 2015.

IEC 61373 — Railway Applications: Rolling Stock Equipment - Shock and Vibration Tests. IEC, 2010.