Introduction

For electronic hobbyists diving into printed circuit board (PCB) design, understanding how to effectively use inner layer traces is a game changer. These conductive pathways, hidden within multilayer PCBs, play a critical role in connecting components while optimizing space and enhancing performance. Inner layer traces allow for denser layouts, improved signal integrity, and reduced electromagnetic interference, making them essential for complex projects. This guide explores the fundamentals of inner layer traces, their importance in PCB trace routing, and practical tips for connecting components. Whether you are designing a simple microcontroller board or a sophisticated gadget, mastering this technique can elevate your skills. Join us as we break down the technical principles and best practices to help you create efficient and reliable designs.

What Are Inner Layer Traces and Why Do They Matter

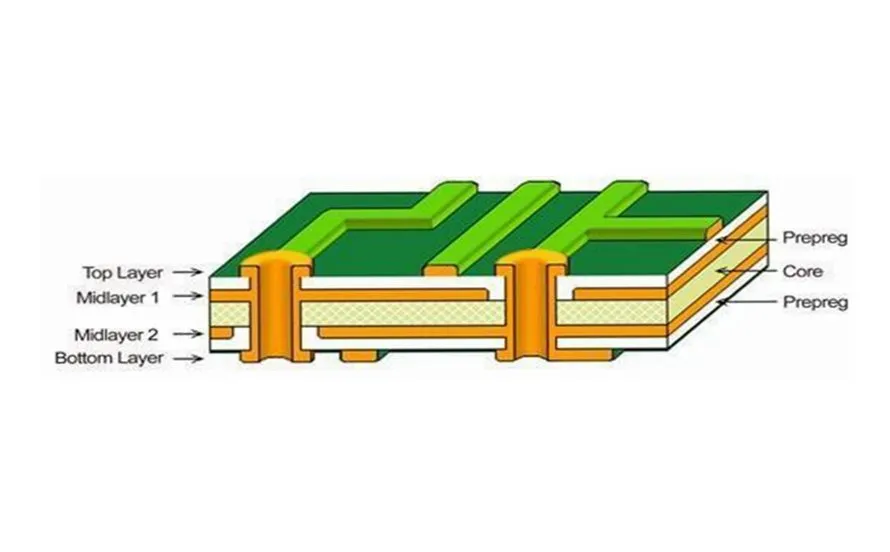

Inner layer traces are conductive copper pathways embedded within the internal layers of a multilayer PCB. Unlike surface traces on the top or bottom layers, these are sandwiched between insulating materials, often forming part of a four layer or higher stackup. They serve the same purpose as external traces, which is carrying electrical signals or power between components, but their placement inside the board offers unique advantages.

The significance of inner layer traces lies in their ability to maximize space. By moving connections to internal layers, hobbyists can free up surface area for additional components or reduce the overall board size. They also help in managing signal integrity by providing shorter paths and reducing noise through proximity to ground planes. For projects involving high speed signals or dense layouts, such as robotics or IoT devices, inner layer traces are indispensable. Additionally, they contribute to better thermal management by distributing heat across internal copper layers. Understanding their role is the first step toward creating compact and efficient PCB designs.

Technical Principles of Inner Layer Traces in PCB Design

The functionality of inner layer traces relies on the structure of multilayer PCBs. A typical four layer board consists of two outer layers for components and signals, and two inner layers often dedicated to power and ground planes or additional signal routing. Inner traces are etched onto these internal copper layers during manufacturing, then insulated by prepreg and core materials before being laminated together.

When connecting components using inner layer traces, vias play a crucial role. These small conductive holes link traces across different layers, allowing signals to transition from surface mounted components to internal pathways. The placement and type of vias, such as through hole or blind vias, impact the design's complexity and performance. Signal integrity is another key consideration. High speed signals routed on inner layers benefit from reduced crosstalk when adjacent to a ground plane, as the plane acts as a shield against interference.

Trace width and spacing on inner layers must also be carefully planned. Narrow traces may overheat under high current, while improper spacing can lead to signal coupling. Industry standards, such as IPC-2221B, provide guidelines for determining safe trace dimensions based on current and temperature rise. Hobbyists should adhere to these principles to ensure reliability.

Suggested Reading: How Does PCB Trace Width Affect Impedance?

Best Practices for Connecting Components with Inner Layer Traces

For electronic hobbyists, routing inner layer traces to connect components can seem daunting, but following best practices simplifies the process. Below are actionable tips to achieve effective PCB trace routing while maintaining design quality.

- Plan Your Layer Stackup Early: Decide the purpose of each layer before routing. Typically, inner layers in a four layer board are used for power and ground to provide a stable reference for signals on outer layers. If additional signal routing is needed internally, ensure it does not interfere with these planes.

- Minimize Via Usage: While vias are necessary for connecting components to inner layer traces, excessive use can increase manufacturing complexity and cost. Route as many connections as possible on a single layer before transitioning through vias. When unavoidable, place vias strategically to avoid clutter.

- Maintain Consistent Trace Widths: Ensure that trace widths on inner layers match the current carrying requirements. Refer to standards like IPC-2221B for guidance on calculating appropriate widths to prevent overheating or voltage drops.

- Use Ground Planes Effectively: Position inner layer traces near a ground plane to reduce electromagnetic interference. This is especially important for high speed signals, as the ground plane helps maintain signal integrity by minimizing noise.

- Avoid Overlapping Signals: When routing multiple signals on an inner layer, keep adequate spacing to prevent crosstalk. Standards such as IPC-6012E emphasize the importance of separation for reliable performance.

By applying these guidelines, hobbyists can create designs that balance functionality with manufacturability.

Common Challenges and Solutions in Inner Layer Routing

Even with careful planning, routing inner layer traces can present challenges for hobbyists. One common issue is signal degradation due to long trace lengths or improper layer transitions. To address this, keep high speed signals as short as possible and avoid unnecessary layer changes. If a transition is needed, ensure vias are placed close to the component pads to minimize inductance.

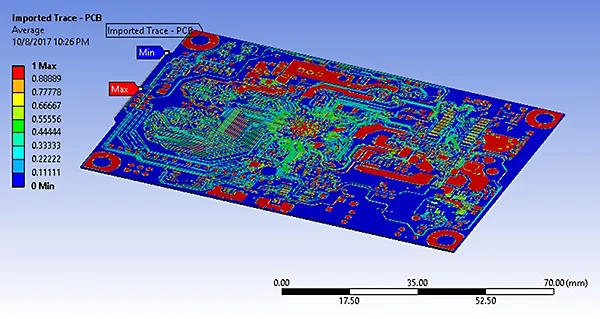

Another challenge is thermal management. Inner layer traces carrying high current can generate heat, which is harder to dissipate compared to surface traces. A solution is to increase trace width or add copper pours on inner layers to spread heat more evenly. Consulting IPC-2221B for current capacity guidelines is advisable.

Lastly, design rule violations can occur when spacing between traces is insufficient, leading to potential short circuits. Using design software with built in rule checking based on standards like IPC-A-600K helps identify and correct such issues before fabrication.

Tools and Techniques for Effective PCB Trace Routing

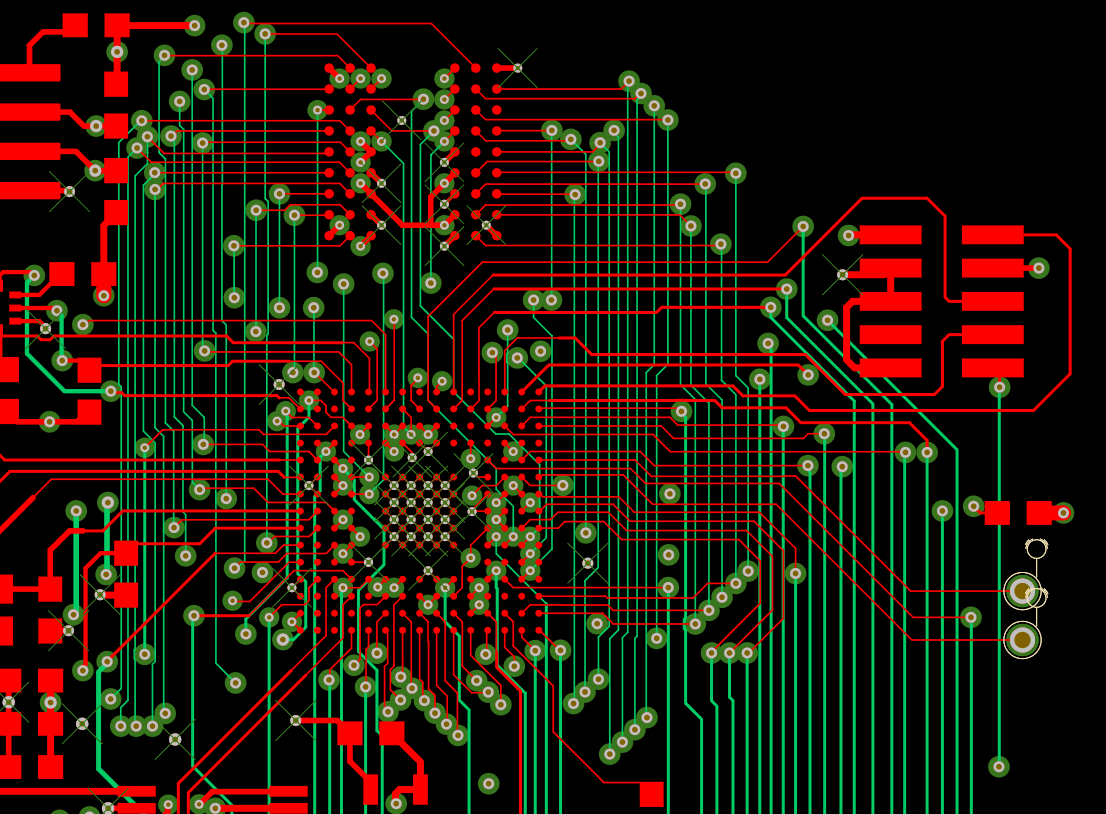

For hobbyists, selecting the right tools and techniques can make inner layer trace routing more manageable. Most modern electronic design automation software offers features to handle multilayer designs. These tools allow you to define layer stackups, assign specific functions to each layer, and automatically check for design rule compliance.

Start by sketching a rough schematic of component connections to identify which signals need inner layer routing. Once the schematic is ready, use the software's layer management feature to allocate traces accordingly. Many platforms provide visual aids to distinguish between layers, making it easier to track inner layer traces.

Manual routing is often necessary for critical signals to ensure optimal paths. However, for less sensitive connections, autorouting features can save time, though they should be reviewed for accuracy. Additionally, simulate your design for signal integrity and thermal performance if the software supports it. This step helps spot potential issues with inner layer traces before sending the design for fabrication.

Conclusion

Mastering the use of inner layer traces is a valuable skill for electronic hobbyists aiming to create compact and high performing PCB designs. These hidden conductive paths enable efficient connecting of components, optimize board space, and enhance signal integrity when used correctly. By understanding the technical principles behind multilayer stackups, adhering to best practices for PCB trace routing, and addressing common challenges, you can elevate the quality of your projects. Applying guidelines from recognized standards ensures reliability and manufacturability. As you experiment with inner layer traces, focus on careful planning and iterative testing to achieve the best results in your electronic endeavors.

FAQs

Q1: What are inner layer traces, and why should hobbyists use them in PCB designs?

A1: Inner layer traces are conductive paths within the internal layers of a multilayer PCB, used for connecting components. They help hobbyists save surface space, allowing for denser designs and smaller boards. Additionally, they improve signal integrity by reducing noise when placed near ground planes, making them ideal for complex or high speed projects.

Q2: How do I ensure proper PCB trace routing on inner layers as a beginner?

A2: Start by planning your layer stackup and assigning specific roles to each layer, such as power or signal routing. Use design software to visualize inner layer traces, maintain consistent trace widths, and minimize vias. Refer to standards like IPC-2221B for guidance on spacing and current capacity to avoid errors.

Q3: What challenges might I face when connecting components with inner layer traces?

A3: Common challenges include signal degradation from long traces, thermal issues with high current, and spacing violations. Address these by keeping traces short, increasing widths for current heavy paths, and using design rule checks based on standards like IPC-A-600K to ensure proper separation and reliability.

Q4: Can inner layer traces improve signal integrity in my hobbyist PCB projects?

A4: Yes, inner layer traces can significantly enhance signal integrity. Routing high speed signals on inner layers near a ground plane reduces electromagnetic interference and crosstalk. This setup stabilizes signals, making it a valuable technique for projects involving microcontrollers or wireless communication modules.

References

IPC-2221B — Generic Standard on Printed Board Design. IPC, 2012.

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.