Introduction

In the highly competitive electronics industry, controlling manufacturing costs for printed circuit boards (PCBs) remains a critical focus for electrical engineers and procurement teams. Reducing expenses without compromising quality requires strategic decisions in material selection, supply chain optimization, and component selection. These areas directly influence production efficiency, yield rates, and overall project budgets. This article explores proven methods to lower PCB manufacturing costs while adhering to industry standards. By understanding the interplay between design choices and manufacturing processes, engineers can implement cost-effective solutions. The following sections provide detailed insights into technical principles and practical strategies, ensuring that quality and performance are maintained throughout the production lifecycle.

Why Reducing PCB Manufacturing Costs Matters

Manufacturing costs for PCBs impact the profitability and scalability of electronic products. High expenses can limit market competitiveness, especially for small to medium enterprises or startups. For electrical engineers, balancing cost with reliability is essential to meet project deadlines and performance expectations. Key cost drivers include raw materials, labor, equipment, and supply chain logistics. Addressing these factors through informed decisions in material selection, supply chain management, and component selection can significantly lower expenses. Moreover, cost reduction aligns with sustainability goals by minimizing waste and optimizing resource use. This section sets the foundation for understanding how targeted strategies can achieve substantial savings without sacrificing board integrity.

Suggested Reading: PCB Cost Calculator: How PCB and Assembly Pricing Is Estimated

Technical Principles Behind PCB Manufacturing Costs

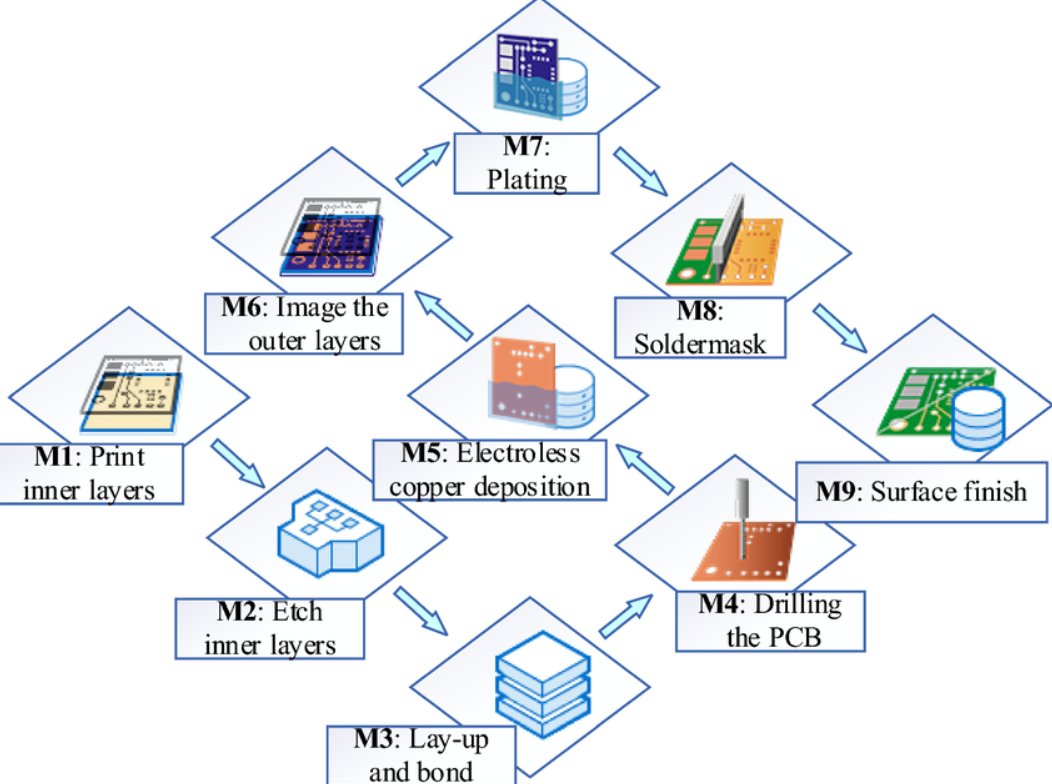

Understanding the core elements that contribute to the PCB manufacturing cost is vital for identifying savings opportunities. Several technical aspects influence expenses during production.

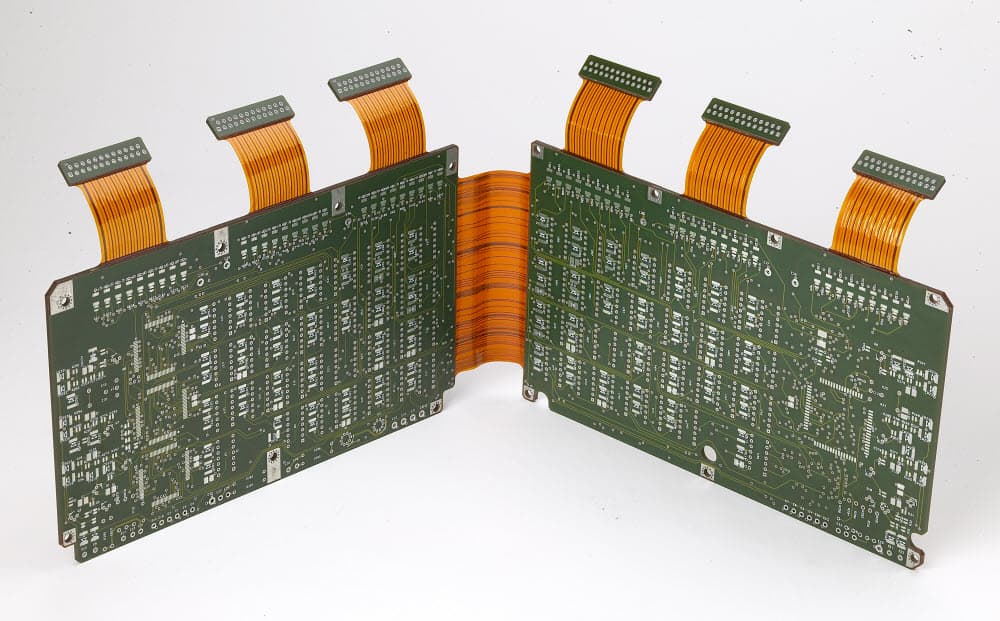

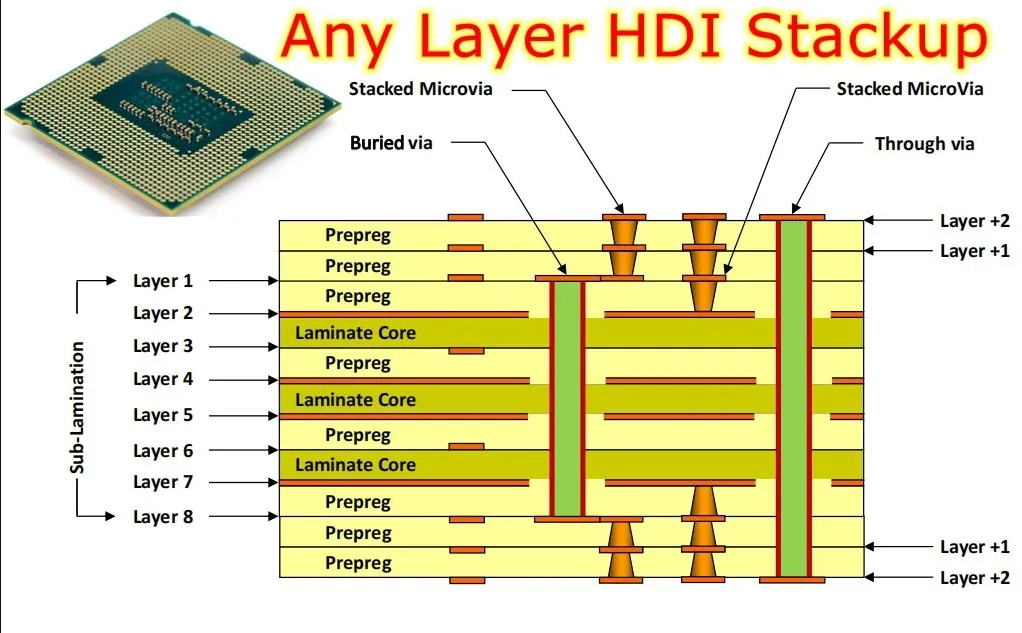

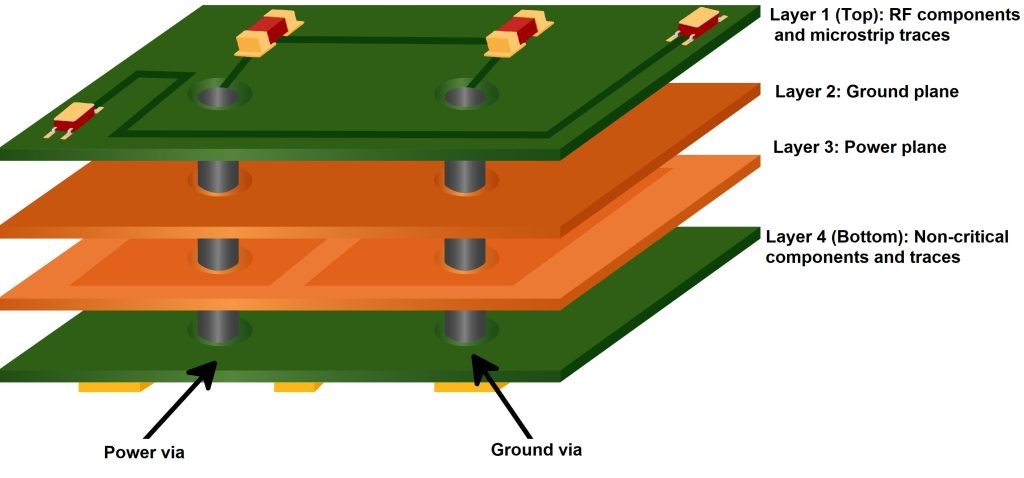

Material Costs and Their Impact

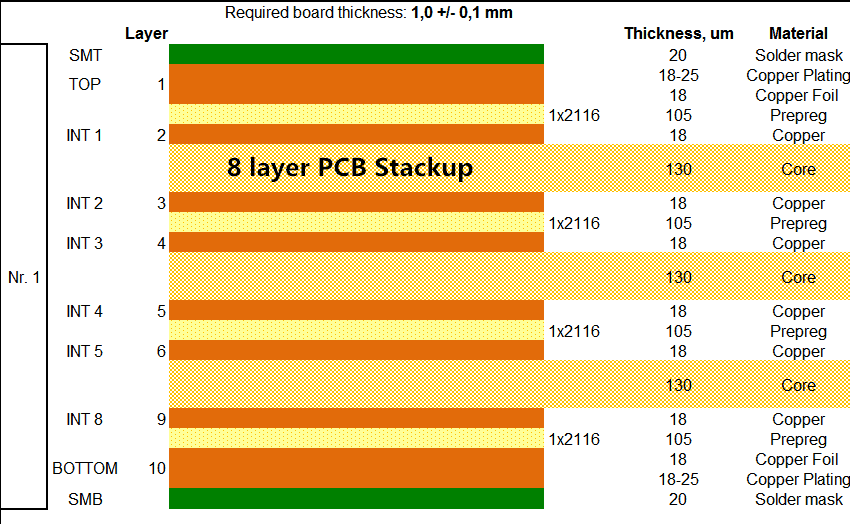

The choice of substrate and conductive materials plays a major role in determining PCB costs. Standard materials like FR-4 are widely used due to their affordability and reliable performance for general applications. However, specialized materials for high-frequency or high-temperature environments can increase expenses significantly. The thickness of copper layers also affects pricing, as thicker layers require more raw material and processing time. Additionally, the number of layers in a PCB directly correlates with cost, as multilayer designs demand more materials and complex fabrication processes.

Related Reading: PCB Material Costs: Choosing the Right Substrate to Balance Performance and Price

Supply Chain Dynamics

Supply chain inefficiencies often contribute to hidden costs in PCB production. Delays in raw material procurement or component shortages can halt manufacturing, leading to increased labor and overhead expenses. Geographic factors, such as sourcing materials from distant suppliers, add shipping costs and extend lead times. Furthermore, inconsistent quality from suppliers may result in rework or scrap, driving up overall costs. A streamlined supply chain reduces these risks by ensuring timely access to high-quality resources at competitive prices.

Component Selection Challenges

The components chosen for a PCB influence both assembly costs and long-term reliability. Non-standard or obsolete parts often carry higher prices due to limited availability. Components with unique footprints or tight tolerances may require specialized assembly equipment, adding to production expenses. Additionally, selecting parts without considering moisture sensitivity or thermal profiles can lead to failures during soldering, increasing rework costs. Strategic component selection ensures compatibility with manufacturing processes while minimizing financial burdens.

Practical Strategies to Reduce PCB Manufacturing Costs

Electrical engineers can adopt several actionable strategies to lower PCB manufacturing costs. These approaches focus on material selection, optimizing the supply chain, and careful component selection, ensuring efficiency at every stage of production.

Material Selection for Cost Efficiency

Choosing the right materials is a foundational step in cost reduction. Opt for standard substrates like FR-4 for non-specialized applications, as they offer a balance of performance and affordability. When multilayer boards are necessary, evaluate the minimum number of layers required to meet design specifications, avoiding over-engineering. Reducing copper thickness where high current is not needed can also save costs without impacting functionality. Additionally, consider surface finishes that align with assembly requirements while adhering to standards such as IPC-6012E for rigid printed boards. Prioritizing widely available materials minimizes procurement delays and price fluctuations.

Optimize Your Supply Chain for Savings

A well-managed supply chain is critical for cost control in PCB manufacturing. Start by building relationships with reliable suppliers who adhere to quality standards like ISO 9001:2015 for quality management systems. Consolidate orders to reduce shipping costs and negotiate bulk pricing for raw materials. Implementing just-in-time inventory practices helps avoid overstocking, which ties up capital and storage space. Additionally, source materials and components locally or regionally when possible to cut down on transportation expenses and lead times. Regularly audit suppliers to ensure consistent quality, preventing costly rework due to defective inputs.

Component Selection for Cost and Compatibility

Thoughtful component selection directly impacts manufacturing expenses and board reliability. Choose components with standard footprints and widely available packages to avoid custom assembly setups. Review datasheets to ensure parts comply with moisture sensitivity classifications as per JEDEC J-STD-020E, reducing the risk of damage during reflow soldering. Avoid obsolete or hard-to-source components that drive up costs due to scarcity. Group similar components in the bill of materials to simplify procurement and assembly, minimizing setup changes on production lines. Finally, consider alternative parts with equivalent specifications to take advantage of better pricing or availability.

Related Reading: PCB Component Cost Calculators: A Comprehensive Guide to Estimating Your Project Budget

Design for Manufacturability

Designing with manufacturing in mind can significantly lower costs. Simplify board layouts by minimizing via counts and avoiding complex routing that requires advanced fabrication techniques. Adhere to design guidelines outlined in standards like IPC-A-600K for acceptability of printed boards to ensure manufacturability. Reduce the board size where possible to decrease material usage, but maintain adequate spacing for assembly processes. Standardize hole sizes and trace widths to avoid the need for specialized tooling. Early collaboration with manufacturing teams can identify potential cost drivers in the design phase, allowing for adjustments before production begins.

Minimize Rework Through Quality Control

Preventing defects during production avoids the high costs associated with rework and scrap. Implement strict quality checks at each stage, from material inspection to final testing, following guidelines in IPC-6012E for performance specifications. Use automated optical inspection systems to detect assembly errors early. Ensure that soldering processes align with thermal profiles specified in JEDEC J-STD-020E to prevent component damage. Maintaining clean production environments reduces contamination risks that lead to board failures. Investing in quality control upfront saves significant expenses compared to addressing issues after production.

Insights from Manufacturing Experience

From a factory-driven perspective, one often overlooked aspect of cost reduction is the importance of communication between design and manufacturing teams. Misalignments in expectations can lead to unnecessary iterations, increasing both time and expense. For instance, a design that specifies tight tolerances beyond standard capabilities may require custom processes, driving up costs. Regular feedback loops during the prototyping phase can align designs with production realities. Additionally, testing small batches before full-scale production helps identify cost-saving opportunities, such as adjusting material choices or streamlining assembly steps. These insights, grounded in practical experience, emphasize proactive planning for cost efficiency.

Conclusion

Reducing PCB manufacturing costs requires a multifaceted approach that addresses material selection, supply chain optimization, and component selection. By choosing cost-effective materials and adhering to industry standards, engineers can minimize expenses without compromising quality. Optimizing the supply chain through strategic sourcing and inventory management eliminates inefficiencies that inflate costs. Thoughtful component selection ensures compatibility with manufacturing processes, reducing assembly challenges. Implementing design for manufacturability and robust quality control further enhances cost savings by preventing rework. These strategies empower electrical engineers to achieve budget goals while delivering reliable, high-performance PCBs for diverse applications.

FAQs

Q1: How does material selection impact PCB manufacturing costs?

A1: Material selection significantly affects PCB manufacturing costs due to variations in price and processing requirements. Choosing standard substrates like FR-4 over specialized materials reduces expenses for general applications. Limiting the number of layers and copper thickness also lowers material usage. Following standards such as IPC-6012E ensures compatibility with cost-effective fabrication processes, avoiding unnecessary expenses from custom materials or rework.

Q2: What are the benefits of optimizing your supply chain for PCB production?

A2: Optimizing your supply chain minimizes delays and reduces costs in PCB production. Sourcing materials locally cuts shipping expenses and shortens lead times. Building reliable supplier networks ensures consistent quality, preventing costly defects. Consolidating orders and adopting just-in-time inventory practices save on storage costs. Adhering to ISO 9001:2015 for quality management further streamlines operations, enhancing overall efficiency.

Q3: Why is component selection critical for reducing PCB costs?

A3: Component selection is vital for cost reduction as it influences both procurement and assembly expenses. Using standard, widely available parts avoids high prices from scarce or obsolete components. Ensuring compatibility with standards like JEDEC J-STD-020E prevents soldering failures, reducing rework. Grouping similar components simplifies assembly, cutting setup costs. Strategic selection balances performance with affordability in PCB manufacturing.

Q4: How can design practices lower PCB manufacturing costs?

A4: Design practices focused on manufacturability directly lower PCB costs by simplifying production. Reducing board size and via counts cuts material usage. Standardizing trace widths and hole sizes avoids specialized tooling. Following guidelines in IPC-A-600K ensures designs align with manufacturing capabilities. Early collaboration with production teams identifies cost drivers, enabling adjustments before fabrication, thus saving time and resources.

References

IPC-6012E - Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K - Acceptability of Printed Boards. IPC, 2020.

JEDEC J-STD-020E - Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices. JEDEC, 2014.

ISO 9001:2015 - Quality Management Systems. ISO, 2015.