Introduction

Soldering stands as a fundamental process in PCB assembly, connecting electronic components to printed circuit boards with precision and reliability. For electronic hobbyists, mastering PCB soldering techniques can transform a simple project into a functional device. Whether working on a small prototype or a complex circuit, understanding the differences between reflow soldering, wave soldering, and manual soldering is vital. Each method offers unique advantages depending on the project scale and component types. Additionally, selecting the right soldering equipment ensures efficiency and quality in every joint. This article explores these techniques in detail, providing practical insights to help hobbyists make informed decisions. By grasping the principles and applications of each method, you can elevate your skills and achieve consistent results in PCB assembly.

What Is Soldering and Why It Matters

Soldering is a process that joins metal surfaces, typically electronic components to a PCB, using a molten metal alloy known as solder. This alloy, often a mix of tin and lead or lead-free alternatives, melts at a low temperature to form a strong electrical and mechanical bond. The significance of soldering in electronics cannot be overstated. It ensures that signals flow without interruption and components remain securely attached despite vibrations or thermal stress.

For hobbyists, soldering is often the bridge between a theoretical design and a working circuit. A poor solder joint can lead to intermittent connections or complete circuit failure. Understanding the right PCB soldering techniques directly impacts the durability and performance of your projects. Whether assembling a simple LED circuit or a microcontroller board, choosing the appropriate method and tools is essential for success.

Technical Principles of Soldering Techniques

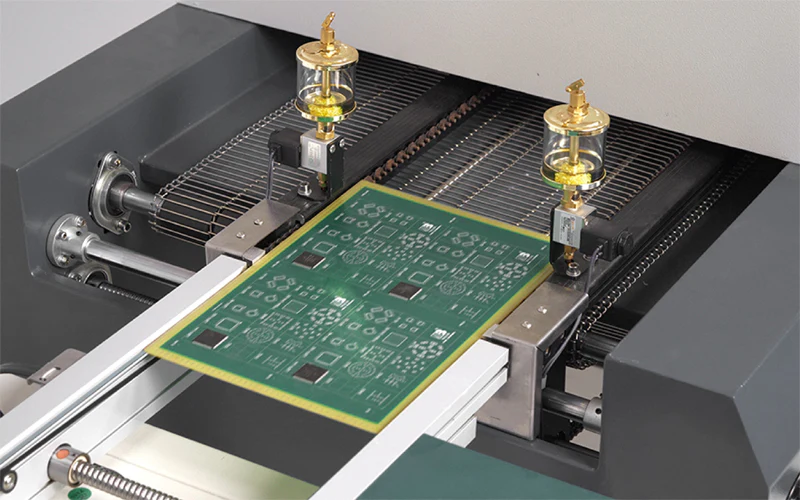

Reflow Soldering

Reflow soldering is a widely used technique for surface mount technology components. It involves applying solder paste, a mixture of tiny solder particles and flux, to the PCB pads. Components are then placed onto the paste, and the entire assembly is heated in a controlled environment, often using a reflow oven. The heat melts the solder, creating solid joints as it cools.

The process follows a specific thermal profile with stages like preheat, soak, reflow, and cooling. This controlled heating prevents thermal shock to components and ensures uniform soldering. According to industry standards such as JEDEC J-STD-020E, managing the reflow profile is critical to avoid issues like component damage or poor wetting. Hobbyists often use small reflow ovens or even modified toaster ovens for small scale projects, though precision in temperature control remains crucial.

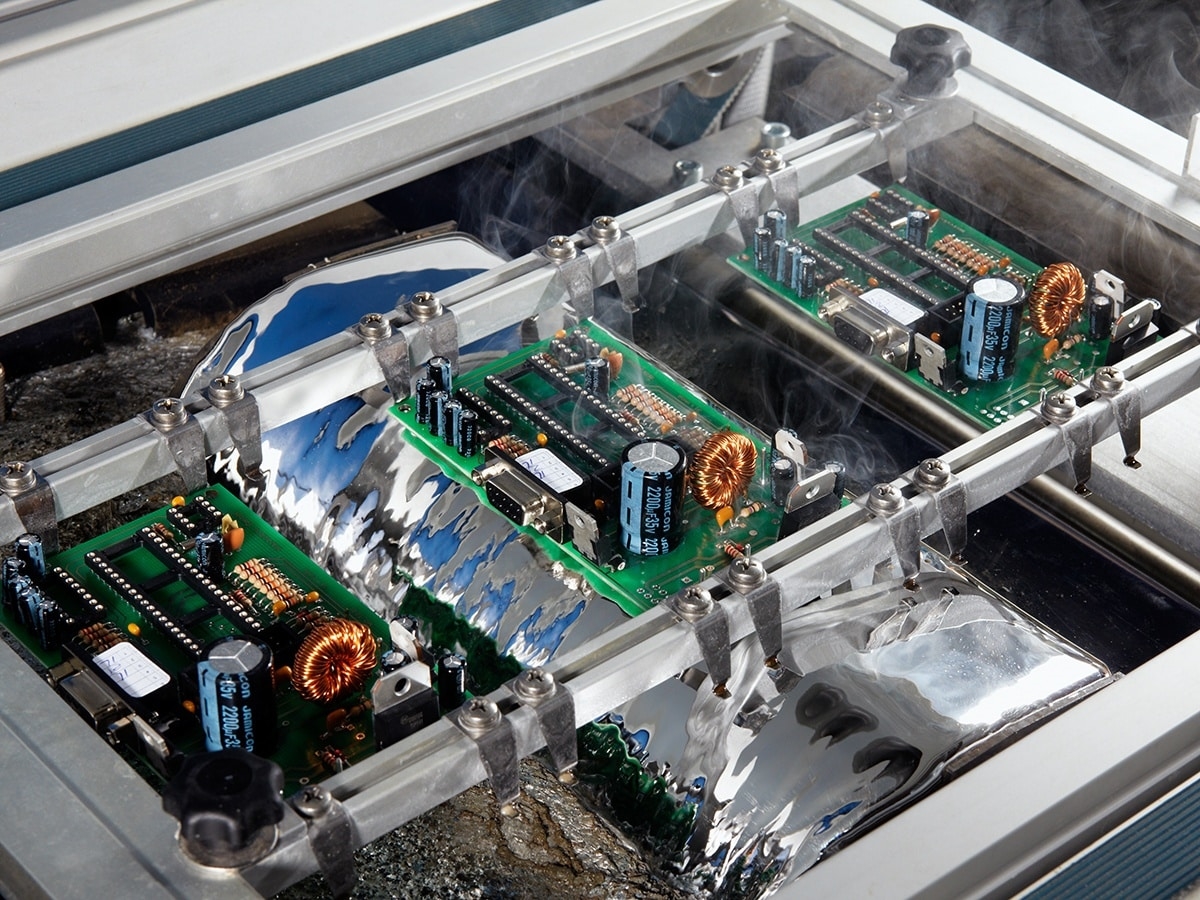

Wave Soldering

Wave soldering suits through hole components and some surface mount parts in larger batches. The PCB passes over a molten solder wave, generated by a pump in a heated solder pot. As the board moves across this wave, solder adheres to exposed metal areas, forming joints on the underside. A flux application before the wave cleans the surfaces for better adhesion.

This technique excels in high volume production due to its speed. However, it is less common among hobbyists because of the equipment size and cost. Standards like IPC J-STD-001H emphasize proper flux application and wave height to prevent defects like bridging between pins. For small projects, wave soldering might be impractical, but understanding its principles can inform decisions on component placement and board design.

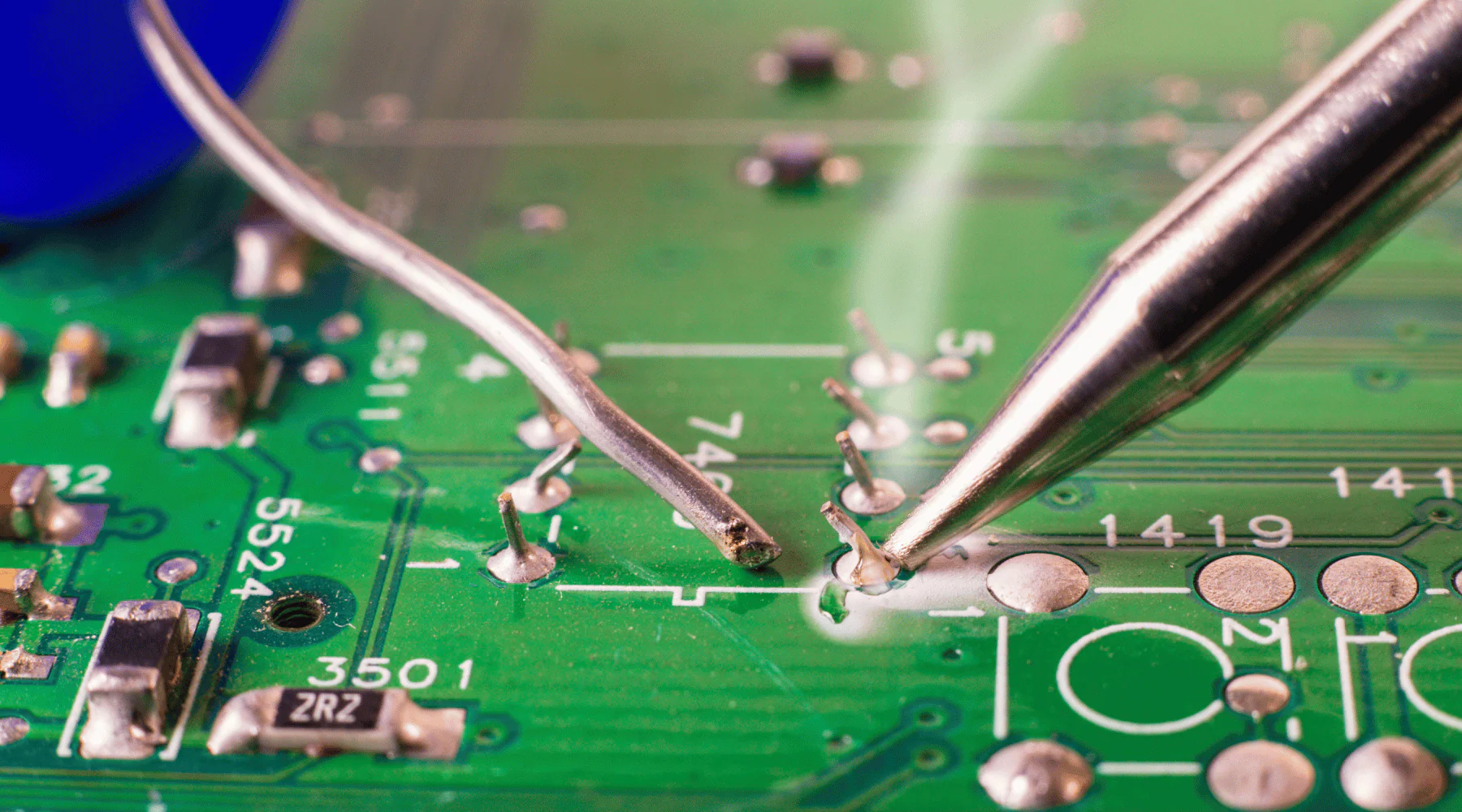

Manual Soldering

Manual soldering, often called hand soldering, involves using a soldering iron to apply solder to individual joints. It is the go-to method for hobbyists due to its simplicity and low cost. A soldering iron heats the joint area, melting solder wire to form a connection between the component lead and PCB pad. Flux, either in the solder core or applied separately, aids in cleaning the surfaces for a strong bond.

This method offers flexibility for small repairs or prototypes. However, it requires skill to avoid cold joints or overheating components. Guidelines from IPC-A-610H highlight the importance of proper tip temperature and contact time to achieve acceptable solder joints. For hobbyists, mastering manual soldering is often the first step in PCB assembly.

Practical Solutions for Choosing the Right Technique

When to Use Reflow Soldering

Reflow soldering works best for projects with surface mount components, especially when dealing with small or densely packed boards. It ensures consistent joints across multiple components simultaneously, reducing manual effort. Hobbyists can adopt this method for complex designs by investing in affordable reflow ovens or using hot air rework stations for smaller tasks. Precision in applying solder paste and following a thermal profile prevents defects. If your project involves tiny chips or multiple ICs, reflow soldering offers efficiency over manual methods.

When to Opt for Wave Soldering

Wave soldering is ideal for through hole components in bulk assembly, though it is less accessible to hobbyists due to equipment constraints. If working on a project with many leaded components like resistors or capacitors, and access to such equipment exists, this method can save time. Ensure proper board orientation and masking of sensitive areas to avoid solder on unwanted zones. For most hobbyists, this technique might only apply when collaborating with a workshop or facility offering wave soldering capabilities.

Mastering Manual Soldering

Manual soldering remains the most practical choice for hobbyists. It suits small scale projects, repairs, or mixed component types. Start with a soldering iron of adjustable temperature to match component needs, typically between 260 to 320 degrees Celsius for common electronics, as per IPC J-STD-001H guidelines. Use a fine tip for precision on small pads and a broader one for larger joints. Apply flux to clean surfaces, and practice on scrap boards to perfect your technique. This method allows full control over each joint, making it versatile for varied tasks.

Soldering Equipment Essentials

Selecting the right soldering equipment is as important as choosing the technique. For manual soldering, a reliable soldering station with temperature control is key. Look for units that allow quick tip changes for flexibility. Solder wire with a rosin core flux simplifies the process for beginners. For reflow soldering, a small benchtop oven or hot air station can suffice for hobbyist needs. Additional tools like tweezers, desoldering braid, and a magnifying glass aid in precision and rework. Always prioritize safety with proper ventilation and heat resistant mats to protect your workspace.

Suggested Reading: A Comprehensive Guide to FR 4 PCB Soldering Techniques and Best Practices

Troubleshooting Common Soldering Issues

Hobbyists often face challenges like cold joints, solder bridges, or component damage during PCBA assembly. A cold joint, appearing dull and grainy, results from insufficient heat or movement during cooling. Reheat the joint with a soldering iron and apply fresh solder to fix it. Solder bridges, where excess solder connects adjacent pads, can be removed using desoldering braid or a suction tool. Overheating components is a risk in manual soldering, so limit iron contact time as advised by IPC-A-610H standards. For reflow soldering, uneven heating might cause tombstoning, where components lift on one side. Adjust the thermal profile or paste application to prevent this. Practice and attention to detail can minimize these issues over time.

Conclusion

Choosing the right soldering technique for PCB assembly depends on your project needs and resources as a hobbyist. Reflow soldering offers efficiency for surface mount components, while wave soldering suits bulk through hole assembly, though it is less common in personal setups. Manual soldering provides the flexibility and control needed for most small scale tasks. Understanding the principles behind each method, paired with suitable soldering equipment, ensures reliable results. By applying best practices and troubleshooting tips aligned with industry standards, you can enhance the quality of your electronic projects. Mastery of PCB soldering techniques opens doors to creating durable and functional circuits with confidence.

FAQs

Q1: What are the main PCB soldering techniques for hobbyists?

A1: For electronic hobbyists, the primary PCB soldering techniques include manual soldering, reflow soldering, and wave soldering. Manual soldering is the most accessible, using a soldering iron for individual joints. Reflow soldering suits surface mount components with a controlled heating process. Wave soldering, though less common for hobbyists, works for bulk through hole assembly. Each method requires specific skills and tools, but manual soldering often serves as the starting point.

Q2: How does reflow soldering differ from manual soldering?

A2: Reflow soldering involves applying solder paste to PCB pads, placing components, and heating the entire board to melt the solder, forming joints uniformly. It is ideal for surface mount parts. Manual soldering uses a soldering iron to apply solder to individual joints, offering control for small projects or repairs. Reflow is faster for multiple components, while manual soldering provides precision for mixed or through hole components.

Q3: What soldering equipment should a beginner hobbyist start with?

A3: Beginner hobbyists should start with basic soldering equipment like a temperature controlled soldering iron, solder wire with flux core, and a stand for safety. Additional tools such as tweezers, a desoldering braid, and a magnifying glass help with precision and rework. A heat resistant mat protects your workspace. These essentials allow you to practice manual soldering effectively before exploring advanced setups for reflow or other techniques.

Q4: When should I consider wave soldering for my PCB projects?

A4: Wave soldering is best for projects with many through hole components and when high volume assembly is needed. It involves passing the PCB over a molten solder wave to create joints quickly. However, the equipment is bulky and costly, making it less practical for most hobbyists. Consider this technique only if you have access to a facility offering wave soldering or are scaling up production significantly.

References

IPC J-STD-001H - Requirements for Soldered Electrical and Electronic Assemblies. IPC, 2021.

IPC-A-610H - Acceptability of Electronic Assemblies. IPC, 2021.

JEDEC J-STD-020E - Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices. JEDEC, 2014.