Introduction

In the fast-paced world of electronics, precision in planning is vital for engineers and designers. Estimating PCB manufacturing time accurately can make or break project timelines. PCB online calculators have emerged as essential tools for providing quick lead time estimations. These digital utilities aim to simplify the complex process of PCB time calculation by factoring in design specifications, material choices, and production variables. However, their accuracy often comes under scrutiny due to the intricate nature of manufacturing processes. This article explores the functionality of PCB online calculators for manufacturing time, their underlying mechanisms, and the factors affecting their precision. Written from an engineering perspective, it offers insights into how these tools can be leveraged effectively for PCB lead time estimation while addressing potential limitations.

What Are PCB Online Calculators and Why Do They Matter

PCB online calculators are web-based tools designed to estimate various aspects of printed circuit board production, including cost, design parameters, and manufacturing time. For electrical engineers, these tools provide a rapid way to gauge project timelines without waiting for manual quotes from suppliers. They typically require inputs such as board dimensions, layer count, material type, and desired turnaround options. The significance of accurate PCB time calculation lies in its direct impact on project scheduling, resource allocation, and meeting market demands. Delays in manufacturing can disrupt product launches, while overestimations may lead to unnecessary costs. As such, PCB manufacturing time tools play a critical role in streamlining workflows and ensuring that engineers can plan with confidence, provided the outputs are reliable.

Suggested Reading: PCB Cost Calculator: How PCB and Assembly Pricing Is Estimated

Technical Principles Behind PCB Lead Time Estimation

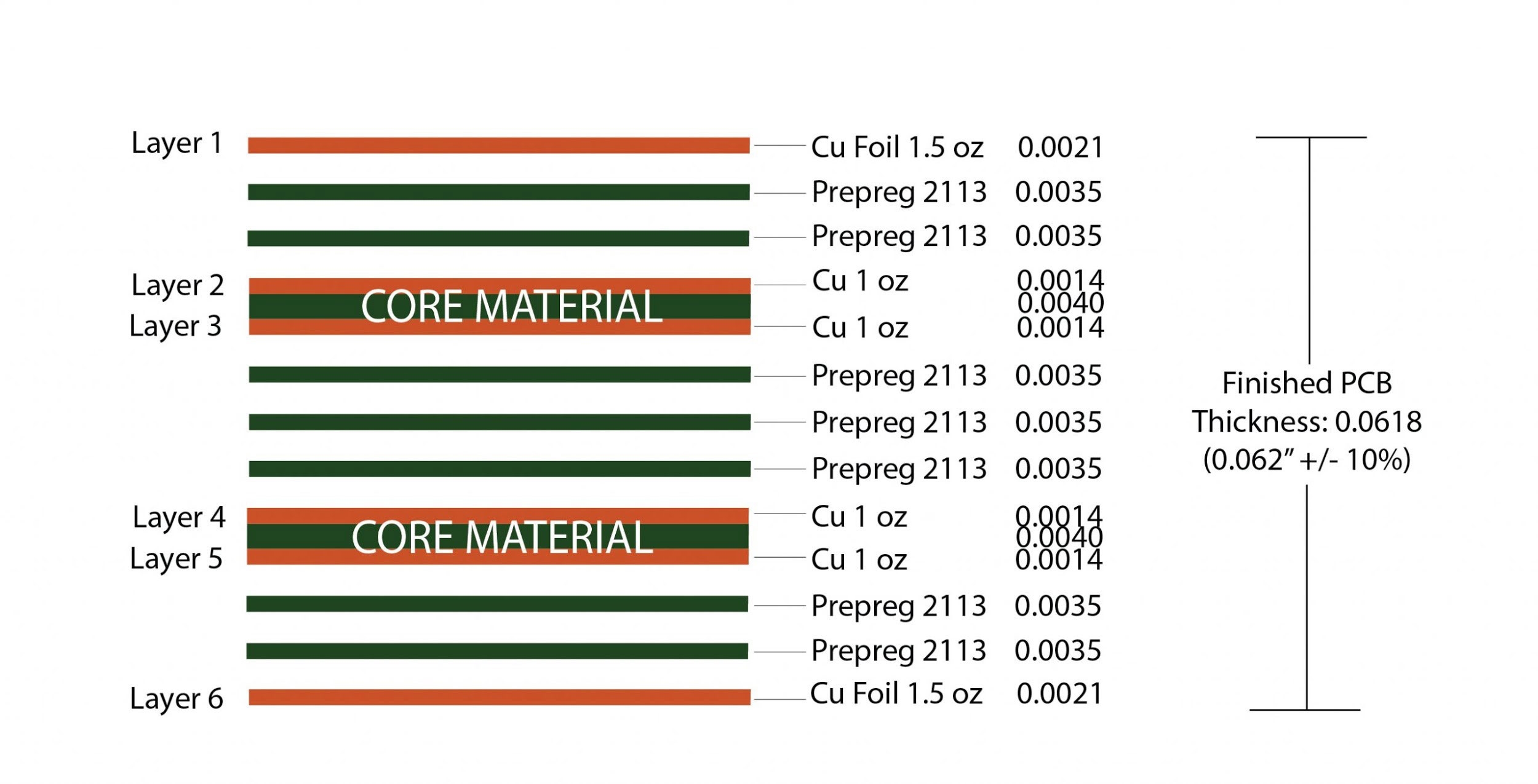

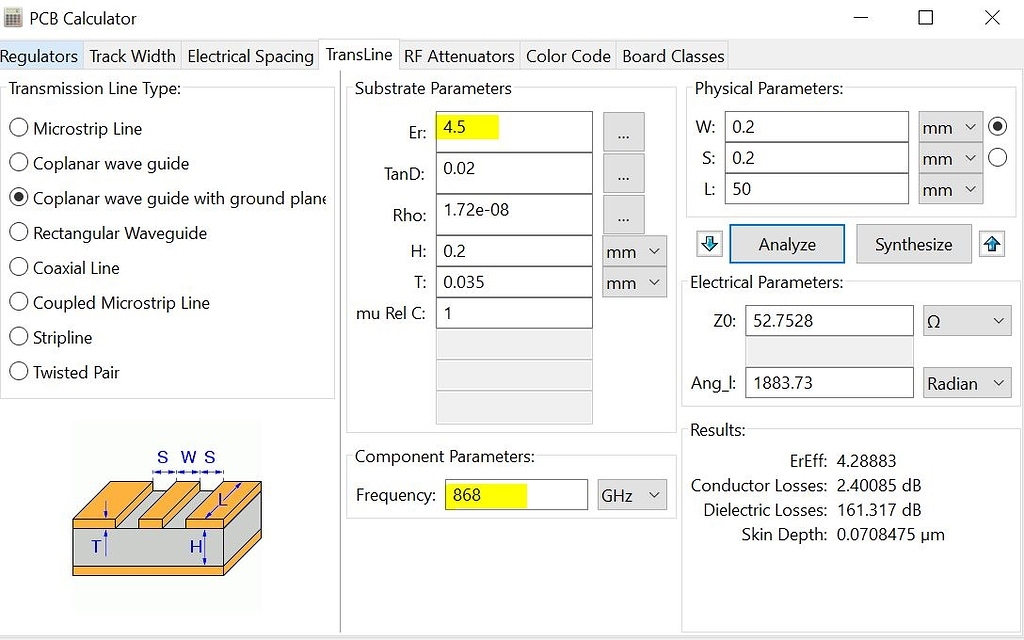

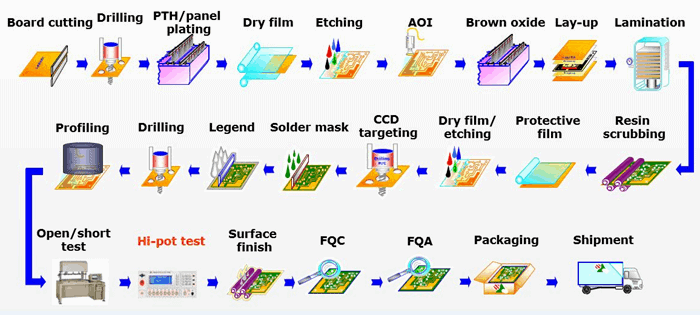

Understanding how PCB online calculators estimate manufacturing time requires a grasp of the variables involved in production. These tools typically rely on predefined algorithms that account for standard industry processes. Key factors include the complexity of the design, such as the number of layers and component density, which directly influence fabrication and assembly duration. Material availability also plays a role, as specialized substrates may require longer procurement times. Additionally, surface finish options and testing requirements, often aligned with standards like IPC-6012E, can extend lead times due to added processing steps.

The calculators often integrate baseline data reflecting typical production schedules for prototype or volume runs. For instance, simpler two-layer boards might follow a standard timeline, while multilayer designs with strict tolerances demand more time for quality checks under standards like IPC-A-600K. However, the accuracy of these tools hinges on the quality of input data and the assumptions embedded in their algorithms. If the tool overlooks variables like factory capacity or shipping delays, the estimation may deviate from reality.

Factors Impacting the Accuracy of PCB Manufacturing Time Tools

Several elements can affect the reliability of PCB online calculators for manufacturing time. First, the completeness of user input is crucial. Incomplete or incorrect data about board specifications can lead to flawed outputs. For example, failing to specify a particular surface finish might result in an underestimation of processing time. Second, the tool’s database must be updated to reflect current industry conditions, such as material shortages or changes in standard lead times.

Another critical factor is the scope of the calculator. Some tools focus solely on fabrication, neglecting assembly or shipping durations, which are essential components of total lead time as defined by industry practices. Moreover, regional differences in manufacturing capabilities are often not accounted for, leading to discrepancies. Standards like ISO 9001:2015 emphasize consistent quality management, yet calculators may not incorporate variations in supplier adherence to such frameworks. Engineers must recognize these limitations and cross-verify estimates with practical experience or direct supplier communication.

Practical Solutions for Improving PCB Time Calculation Accuracy

To maximize the utility of PCB online calculators for manufacturing time, engineers can adopt several best practices. Start by providing detailed and accurate design data when using these tools. This includes specifying layer count, board dimensions, and any special requirements like impedance control, which may affect production under guidelines like IPC-6012E. Always double-check the default settings of the calculator to ensure they align with your project needs.

Additionally, use PCB manufacturing time tools as a preliminary guide rather than a definitive answer. Cross-reference the estimates with historical project data or consult with manufacturing partners for validation. It is also beneficial to select calculators that allow customization of inputs, as they are more likely to account for unique project variables. Finally, stay informed about industry trends that might influence lead times, such as supply chain disruptions, to adjust expectations accordingly.

Challenges in Relying Solely on PCB Online Quote Time Tools

While PCB online quote time tools offer convenience, over-reliance can lead to planning errors. One major challenge is the lack of transparency in how these calculators derive their estimates. Without insight into the underlying algorithms, engineers cannot fully assess their reliability. Additionally, these tools often fail to account for unforeseen delays, such as equipment downtime or quality rejections during inspections aligned with IPC-A-600K standards.

Another issue is the variability in manufacturing environments. A calculator might assume ideal conditions, ignoring real-world constraints like batch processing or holiday schedules. For critical projects, this can result in significant discrepancies between estimated and actual lead times. Engineers should treat these tools as a starting point, supplementing them with direct communication and contingency planning to ensure robust project management.

Best Practices for Combining Tools with Manual Verification

Achieving accurate PCB lead time estimation often requires a hybrid approach. Begin by using PCB online calculators to obtain a baseline estimate of manufacturing time. Then, validate these figures through manual methods, such as reviewing past project timelines or consulting with production teams. This dual strategy helps identify potential gaps in the tool’s assumptions.

Moreover, document specific project requirements in detail to ensure all variables are considered. For instance, if a design necessitates additional testing per IPC standards, factor in the extra time manually if the calculator does not. Regularly update internal records of lead times to build a reliable reference dataset. This practice not only improves future estimations but also enhances decision-making for urgent projects. By blending digital tools with practical insights, engineers can achieve a balanced and realistic view of production schedules.

Conclusion

PCB online calculators for manufacturing time serve as valuable aids for electrical engineers seeking quick lead time estimations. They simplify the complex task of PCB time calculation by processing design and production variables into actionable insights. However, their accuracy depends on the quality of input data, the scope of the tool, and the ability to reflect real-world manufacturing conditions. While these PCB manufacturing time tools offer a convenient starting point, they should be complemented with manual verification and industry knowledge to ensure reliable planning. By understanding their limitations and applying best practices, engineers can effectively integrate these calculators into their workflow, achieving better control over project timelines and delivery schedules.

FAQs

Q1: How do PCB online calculators improve manufacturing time estimation?

A1: PCB online calculators streamline manufacturing time estimation by automating the process with user-provided design data like layer count and material type. They generate quick results for PCB lead time estimation, reducing the wait for manual quotes. However, their accuracy relies on detailed inputs and updated algorithms reflecting current industry standards.

Q2: What limits the accuracy of PCB time calculation tools?

A2: The accuracy of PCB time calculation tools can be limited by incomplete user inputs, outdated databases, and unaccounted variables like shipping delays. Many tools overlook factory-specific constraints or assembly times. Engineers must verify estimates manually to ensure realistic timelines for their projects.

Q3: How can engineers enhance PCB manufacturing time tools' reliability?

A3: Engineers can boost the reliability of PCB manufacturing time tools by entering precise design specifications and cross-checking outputs with past project data. Combining tool estimates with direct supplier feedback helps account for real-world factors, ensuring more accurate planning and scheduling.

Q4: Why is manual verification important for PCB online quote time?

A4: Manual verification is crucial for PCB online quote time because calculators may miss critical factors like production bottlenecks or regional differences. Verifying estimates with historical data or supplier input ensures more dependable timelines, preventing costly delays in project execution.

References

IPC-6012E - Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K - Acceptability of Printed Boards. IPC, 2020.

ISO 9001:2015 - Quality Management Systems. ISO, 2015.