Background

With rapid technological development, electronic products are moving toward miniaturization and higher integration, such as flexible electronic devices and light-emitting diodes. Heat dissipation has become a key technical challenge. The three primary heat transfer modes are conduction, convection, and radiation. Because heatsinks in electronic products are typically small, convection contributes relatively little to overall cooling. Heat inside devices is mainly transferred to the air by conduction and thermal radiation.

Traditional heatsink materials are high-thermal-conductivity metals, which provide good heat dissipation. However, metals are prone to corrosion when exposed to moisture, which can damage substrates and create safety concerns. To address this, metal heatsinks are often coated with an anti-corrosion layer. These coatings are typically resin-based polymers with low thermal conductivity, which substantially limits the heat dissipation efficiency of the device.

Preparation of thermally conductive polymer coatings commonly involves adding inorganic fillers to a polymer matrix to increase thermal conductivity. However, mismatch between the phonon spectra of the polymer matrix and inorganic fillers weakens lattice vibration transmission at the interface, increasing interfacial thermal resistance and reducing overall thermal conductivity. To improve composite thermal performance, high-thermal-conductivity fillers are selected. Graphene has exceptionally high thermal conductivity, good electrical conductivity, strong mechanical properties, and a large specific surface area. At room temperature its thermal conductivity can reach up to 5000 W/(m·K). Consequently, graphene is used as a high-thermal-conductivity filler to enhance coating and material heat transfer. Adding graphene to polymers can significantly improve radiative cooling performance and overall cooling efficiency.

Key Results

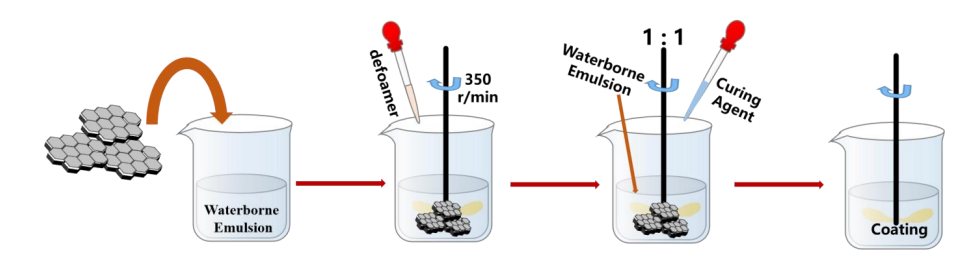

A research team at the Engineering Research Center for Coal-based Ecological Carbon Sequestration developed a graphene-containing waterborne thermal coating to improve cooling performance on stainless steel substrates. Graphene produced by liquid-phase exfoliation was used as the functional additive. The study showed that thermal conductivity of the coatings varies significantly with graphene loading. At 15% graphene content, the coating reached a thermal conductivity of 9.499 W/(m·K), enabling rapid heat dissipation.

The coatings were evaluated for comprehensive performance under realistic operating conditions. They demonstrated strong corrosion resistance and good temperature cycling stability. In laboratory tests, applying the coating to stainless steel substrates noticeably improved cooling. Compared with uncoated samples, the maximum temperature difference during heat transfer at room temperature reached 11°C, and at -80°C reached 19°C. The coating shows potential for thermal management applications. The results were published as "Preparation and Performance Evaluation of Graphene-based Waterborne Thermal Conductive Coatings" in Surface & Coatings Technology.

Figures

Figure 1. Preparation process for the graphene waterborne high-thermal-conductivity coating.

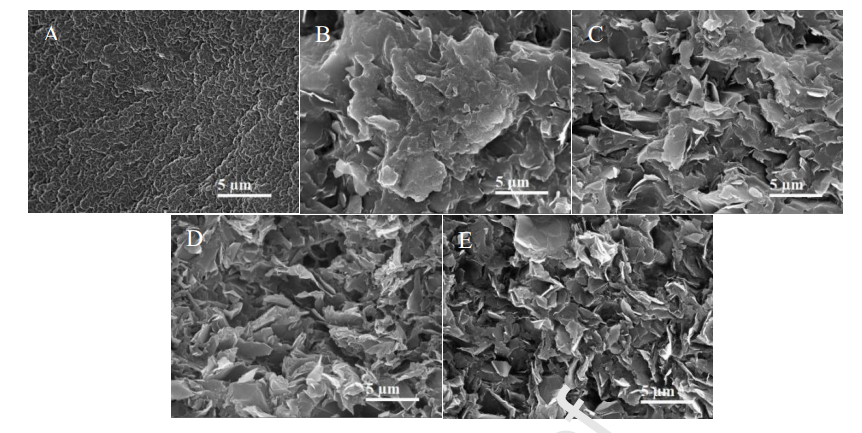

Figure 4. Microstructures of coatings prepared with different graphene additions.

Figure 5. Water resistance tests for coatings with different graphene contents.