Why Design a Custom PCB for Motor Control?

Building your own electric motor drive PCB offers unparalleled flexibility compared to readily available options. It allows you to fine-tune the board for specific voltage and current needs, as well as integrate unique control algorithms. This level of customization is crucial for applications where factors like size, power efficiency, and overall performance are critical, such as in drones, electric vehicles, or automated machinery.

For example, a motor driver PCB designed specifically for an application can efficiently manage high currents, potentially exceeding 50A, while maintaining a compact footprint, perhaps no larger than a credit card. Beyond raw performance, a custom approach enables the integration of specialized functions like sensor feedback or wireless connectivity, which are often absent in generic boards. This tailored method is also more economical for large-scale production or highly specialized projects.

What Are the Initial Steps in Custom Motor Drive PCB Design?

Defining Your Motor Control Needs

Before initiating any design work, it's essential to clearly define the purpose and specifications of your motor drive PCB. Start by identifying the type of motor you'll be controlling—whether it's a DC, brushless DC (BLDC), or stepper motor—and its operational requirements.

Key factors to consider include:

● Voltage and Current: Specify the input voltage (e.g., 12V, 24V, 48V) and the continuous current draw of your motor (e.g., 10A, 30A).

● Control Method: Determine the required control strategy, such as simple on/off, speed regulation using Pulse Width Modulation (PWM), or precise position control with encoder feedback.

● Operating Environment: Assess conditions like temperature extremes or humidity, as these will influence component selection and board materials.

● Physical Constraints: Establish the board's maximum dimensions to ensure it fits within its intended device or enclosure.

For instance, a BLDC motor in a drone might require a PCB capable of 24V input, 20A continuous current, and PWM for variable speed. Documenting these specifications meticulously prevents critical oversights during the design process.

Selecting Appropriate Components

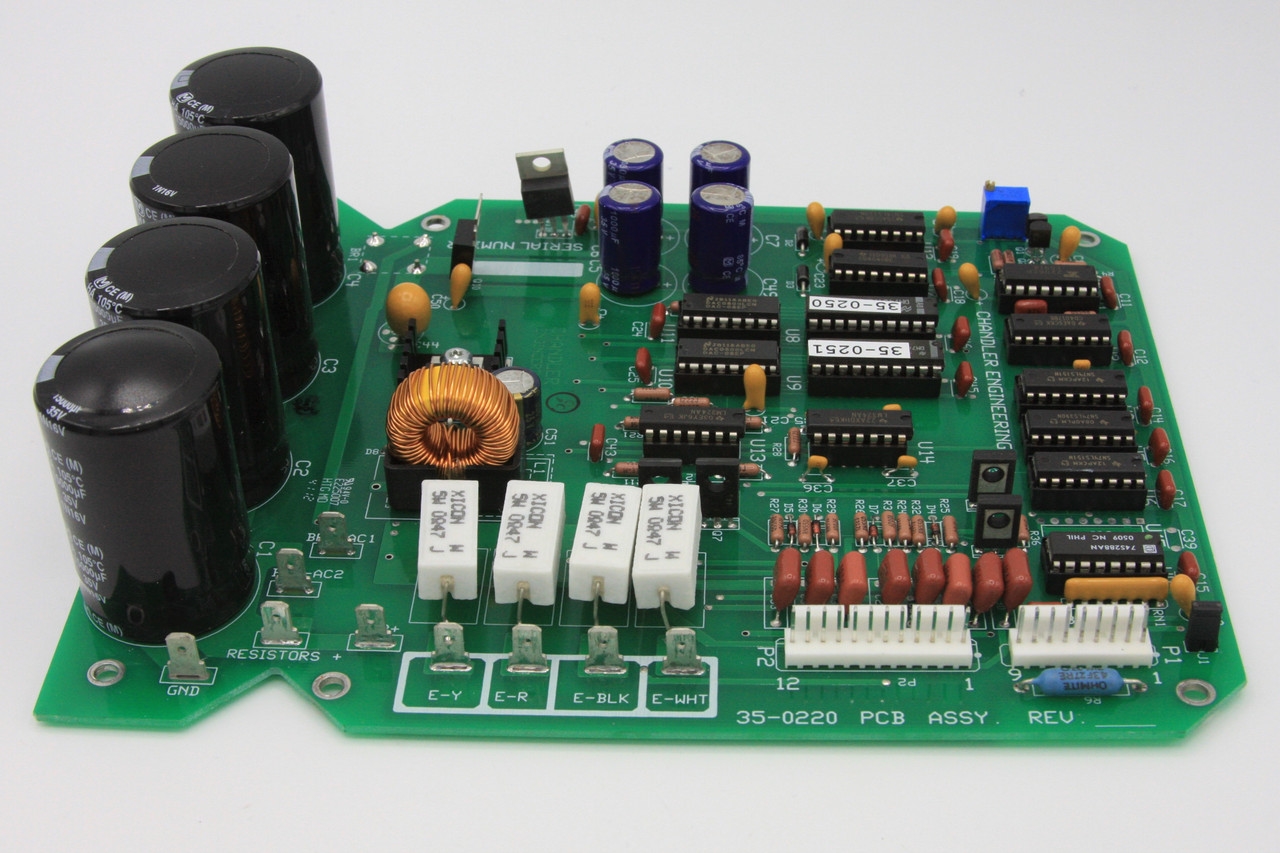

Component selection is a pivotal stage in designing a bespoke motor drive PCB, as each part must align with your specifications to guarantee reliability and optimal performance.

Focus on these essential components:

● Microcontroller (MCU) or Driver IC: Choose a controller that supports your desired method, such as an MCU with integrated PWM channels for speed control.

● Power MOSFETs or IGBTs: These are critical for managing high currents and voltages. Their ratings should comfortably exceed your motor’s requirements, ideally by at least 20%, to ensure a safety margin. For a 30A motor, select MOSFETs rated for 36A or higher.

● Capacitors and Resistors: Capacitors are used for voltage stabilization and noise reduction, with electrolytic types (e.g., 1000µF at 50V) being common in high-current applications.

● Sensors (Optional): If feedback is necessary, incorporate hall effect sensors or encoders for data on position and speed.

Always refer to component datasheets for details on thermal limits and compatibility. Using an under-rated component, like a MOSFET with insufficient current handling, can lead to overheating or catastrophic failure under load.

How Do You Create the Schematic and PCB Layout?

Developing Your Custom PCB Schematic

Once components are chosen, the next step is to create a schematic, which acts as a circuit blueprint. Utilize specialized PCB design software to draw the circuit, paying close attention to several key areas.

Important aspects of schematic design:

● Power Supply: Design a robust power input section with adequate filtering to manage voltage spikes. Consider adding a reverse polarity protection diode if needed.

● Control Logic: Connect your MCU or driver IC to generate control signals, such as PWM. It's crucial to isolate these signal lines from high-power traces to prevent electromagnetic interference (EMI).

● Motor Output: Route the high-current paths from the MOSFETs directly to the motor terminals, ensuring minimal resistance. Use appropriately wide traces for these connections.

To reduce noise, place small decoupling capacitors (e.g., 0.1µF ceramic) as close as possible to the MCU’s power pins. This helps prevent voltage drops during sudden current demands. If feasible, simulate your schematic to identify potential errors before proceeding to the physical layout.

Designing the PCB Layout for Motor Control

The PCB layout transforms your schematic into a tangible board. An effective layout is crucial for minimizing noise, managing heat, and reducing signal loss.

Consider these layout best practices:

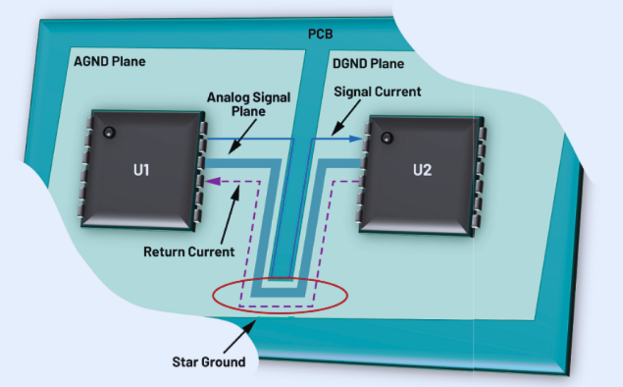

● Trace Separation: Maintain clear separation between high-current traces (e.g., motor outputs) and sensitive signal lines to mitigate EMI.

● Power Trace Width: For high-current paths, calculate trace width using online tools. A 30A trace with 1oz copper might require a width of approximately 200 mils.

● Thermal Management: Incorporate copper pours or strategically placed vias beneath power components like MOSFETs to effectively dissipate heat. For currents above 20A, consider a 4-layer board for superior heat distribution.

● Ground Plane: Implement a solid ground plane to minimize noise and provide a stable reference for all signals.

Careful component placement is also vital; group related parts, such as the driver IC and MOSFETs, closely to shorten trace lengths. A compact layout conserves space and reduces parasitic inductance, which can otherwise cause voltage spikes at high frequencies.

What Materials and Testing Are Needed for a Custom Motor Drive PCB?

Selecting Board Materials and Layer Stack-Up

The choice of materials and the layer stack-up significantly influence the durability and performance of your PCB. For motor control applications, consider these options.

Material considerations:

● Base Material: FR-4 is a common and cost-effective choice suitable for most designs, handling temperatures up to 130°C for moderate power.

● Copper Thickness: Opt for 2oz copper in high-current designs (above 10A) to minimize resistance and heat buildup. Standard 1oz copper is generally adequate for lower current applications.

● Layer Count: A 2-layer board can suffice for simpler motor drivers, but a 4-layer board offers enhanced grounding and thermal management for more complex designs.

For example, a 4-layer board with 2oz copper can safely manage 40A currents with less risk of overheating than a 2-layer, 1oz design. Collaborate with your PCB manufacturer to strike a balance between cost and performance based on your specific requirements.

Prototyping and Rigorous Testing

Once your design is finalized, order a prototype to validate its functionality thoroughly. Comprehensive testing is indispensable before proceeding to full-scale production.

Steps for effective prototyping and testing:

● Visual Check: After assembly, perform a meticulous visual inspection for any soldering flaws or misaligned components.

● Power-Up Test: Apply power without the motor connected. Measure voltages at critical points to confirm they align with your design (e.g., 5V for logic, 24V for power).

● Load Test: Connect the motor and operate it under typical conditions. Monitor component temperatures using a thermal camera; MOSFETs, for instance, should not exceed 80°C under load.

● Signal Integrity: Use an oscilloscope to verify PWM signals and feedback data. Look for clean, undistorted waveforms free from excessive noise.

Should issues arise, such as overheating or signal glitches, reassess your layout or component selections. Iterative prototyping is a standard and necessary part of refining a custom PCB motor driver.

Optimizing for Production and Overcoming Challenges

Preparing for Efficient Production

After successful testing, it's time to prepare your design for manufacturing, focusing on cost-effectiveness and scalability.

Tips for production optimization:

● Design for Manufacturability (DFM): Ensure your design adheres to standard fabrication guidelines, including minimum trace widths (e.g., 6 mils) and clearances.

● Bill of Materials (BOM): Compile a comprehensive BOM that includes part numbers and suppliers to streamline the assembly process.

● Panelization: If producing multiple boards, arrange them in a panel to reduce overall fabrication costs.

Work closely with your PCB manufacturer to finalize details such as the surface finish (e.g., ENIG for durability) and solder mask color. Clear communication at this stage helps prevent delays and errors during production.

Addressing Common Design Hurdles

Even with meticulous planning, designing a custom PCB motor driver can present challenges.

Common issues and their solutions:

● Heat Dissipation: High currents inevitably generate heat. Employ heat sinks or increase copper thickness if components are overheating.

● EMI Noise: Poor grounding or excessively long traces can introduce noise. Shorten signal paths and use shielded components when necessary.

● Component Availability: Supply chain disruptions can cause project delays. Select readily available parts or have viable backup options.

Anticipating these potential problems during the design phase can significantly save time and resources. For example, proactively adding extra vias for heat dissipation during the layout stage can prevent thermal issues down the line.

Essential Tools and Resources for Custom PCB Design

Designing a custom electric motor PCB is greatly facilitated by access to the right tools.

Useful categories of resources:

● Design Software: Utilize Computer-Aided Design (CAD) tools for creating schematics and layouts. Many options offer free versions for students and hobbyists.

● Simulation Tools: Simulate circuit behavior to predict performance before physical construction, helping to identify errors early.

● Online Calculators: Tools for trace width, via current capacity, and impedance control are invaluable for optimizing layout.

Additionally, online communities and forums offer a wealth of tutorials and advice for beginners. Learning from the experiences of others can significantly accelerate your progress in creating a custom motor control board.

Conclusion: Embarking on the journey of designing a custom electric motor drive PCB is a highly rewarding endeavor, enabling you to craft bespoke solutions for your projects. By diligently following this comprehensive, step-by-step guide—from defining requirements and selecting components to creating schematics, laying out the board, and thoroughly testing prototypes—you can develop a reliable and efficient motor driver. Whether you're engaged in a personal DIY motor control PCB project or a professional application, unwavering attention to detail and iterative testing are paramount to achieving success. With the correct methodology, challenges such as heat management and electromagnetic interference can be effectively overcome, ensuring your board performs precisely as intended. Collaborating with a trusted PCB manufacturing service, like AIVON, will help bring your design to fruition, and continuous practice will undoubtedly refine your skills. Begin your custom PCB design for motor control today and discover the boundless possibilities for innovation it offers.