Why Is Material Selection Critical for Pacemaker PCBs?

Designing printed circuit boards (PCBs) for pacemakers involves far more than just ensuring electrical functionality; it's a matter of patient safety and long-term health. Pacemakers are vital implantable medical devices responsible for regulating heartbeats, meaning their PCBs must operate flawlessly for extended periods within the challenging environment of the human body. This necessitates the use of materials that are not only biocompatible—meaning non-toxic and non-reactive with biological systems—but also exceptionally durable under physiological conditions, such as constant moisture exposure and temperature fluctuations. Crucially, these materials must also maintain stable electrical performance with minimal signal degradation over time.

A suboptimal material choice can lead to severe consequences, including device failure, adverse immune responses from the patient's body, or even direct physical harm. As an engineer in this specialized field, the primary objective is to strike a delicate balance between optimal electrical performance, proven biocompatibility, and unwavering reliability. For instance, a typical pacemaker PCB must reliably handle low-power signals, often with impedances between 50 and 100 ohms, ensuring their integrity remains uncompromised over years of continuous operation.

What Are the Key Criteria for Choosing Pacemaker PCB Substrates?

The process of selecting a substrate for a pacemaker PCB goes beyond a simple material choice; it's a fundamental decision that underpins the device's long-term success and patient safety. Several critical factors must be rigorously evaluated during this crucial pacemaker PCB substrate selection process.

Biocompatibility Standards

Foremost, the material chosen must not provoke adverse immune responses or leach toxic substances into the body. Adherence to stringent standards, such as ISO 10993, which mandates comprehensive testing for cytotoxicity and irritation, is absolutely essential. Any material in contact with the human body, whether directly or indirectly, must unequivocally meet these rigorous biocompatibility requirements.

Electrical Performance Requirements

To minimize signal loss, especially for the high-frequency signals increasingly prevalent in modern pacemakers, the substrate must exhibit a low dielectric constant (Dk) and a low dissipation factor (Df). Ideally, a Dk value below 3.5 and a Df below 0.005 are sought to ensure precise signal transmission and maintain electrical integrity within the compact circuitry.

Mechanical Stability and Durability

The substrate must possess exceptional resistance to cracking, delamination, or fatigue under continuous mechanical stress. Given that pacemakers are subjected to constant movement with every heartbeat, the material's flexibility and overall durability are paramount to prevent structural failures that could compromise device function over its operational lifetime.

Thermal and Chemical Resistance

The chosen material must maintain its properties when exposed to the sustained body temperature (approximately 37°C) and be capable of dissipating any localized heat generated by the electronic circuitry without degradation. Furthermore, it must exhibit robust chemical resistance to bodily fluids like blood or saline, preventing moisture absorption and chemical breakdown that could lead to material corrosion or performance decay over time.

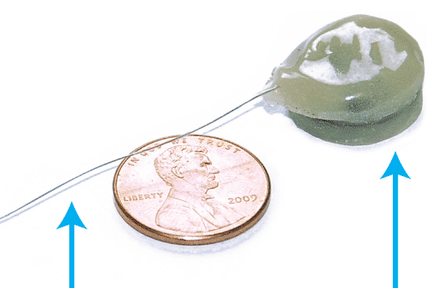

Supporting Miniaturization Efforts

With pacemakers continually shrinking in size, the PCB substrate must facilitate miniaturization, supporting the creation of ultra-fine-line traces (often below 50 microns) for highly compact and sophisticated designs. This capability is vital for integrating more functionality into smaller form factors, addressing the ongoing demand for less invasive and more comfortable medical implants.

What Are the Leading Biocompatible PCB Materials for Pacemakers?

Given the stringent requirements for implantable medical devices, several high-performance materials stand out as preferred choices for pacemaker PCBs. Each offers a unique combination of properties tailored for the extreme demands of the human body.

Polyimide for Flexible and Rigid-Flex Designs

Polyimide is a highly favored material for medical implant PCBs, including pacemakers, largely due to its exceptional flexibility and proven biocompatibility. It is extensively utilized in manufacturing flexible and rigid flex PCBs, allowing boards to bend and conform without structural failure—a critical feature for devices that must adapt to the body’s internal contours or endure constant movement. Polyimide offers high thermal stability (withstanding up to 260°C), excellent resistance to chemicals, and a low dielectric constant (around 3.4), all contributing to minimal signal interference. Its applications are widespread in pacemaker leads and intricate interconnects where space is constrained and flexibility is non-negotiable. While polyimide can be more costly than the standard PCB FR-4 material, and its moisture absorption (around 1-3%) requires robust encapsulation, it remains a reliable choice when properly sealed against bodily fluids.

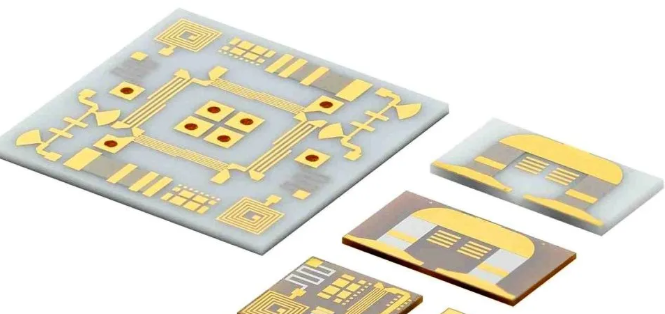

Rogers Materials for High-Frequency Performance

Rogers Corporation manufactures high-performance laminates that have become increasingly popular in advanced medical device design, particularly for pacemaker PCBs. As a leading material choice for Rogers PCB, materials from series like Rogers RO3000 and RO4000 are well-regarded for their exceptionally low dielectric loss and consistent performance, even at high frequencies. These materials typically feature a dielectric constant between 3.0 and 3.5 and a remarkably low loss tangent, often as low as 0.001. This makes Rogers PCB solutions ideal for preserving signal integrity within the compact and often high-frequency circuits found in modern pacemakers, especially for RF components such as wireless communication modules enabling remote patient monitoring. While Rogers laminates are generally more expensive and their rigidity may limit their use in highly flexible designs, their superior electrical properties often justify the investment for critical high-frequency applications.

Ceramic Substrates for Extreme Reliability

Ceramic substrates, including materials like alumina (Al2O3) and aluminum nitride (AlN), are employed in pacemakers for their unparalleled reliability and inherent biocompatibility. These materials are often chosen for hybrid circuits or in scenarios where extreme durability and thermal management are paramount. Ceramics boast excellent thermal conductivity (up to 30 W/mK for AlN), superior mechanical strength, and virtually zero moisture absorption. Their dielectric constant can range from 8 to 10, making them suitable for specific high-density designs, especially in power management circuits within pacemakers where efficient heat dissipation is crucial. However, ceramics are inherently brittle and their processing is significantly more expensive, often demanding specialized manufacturing techniques. Despite these challenges, ceramics remain a powerful, albeit niche, option for engineers who prioritize absolute reliability and thermal performance over flexibility in biocompatible PCB materials for pacemakers.