Introduction

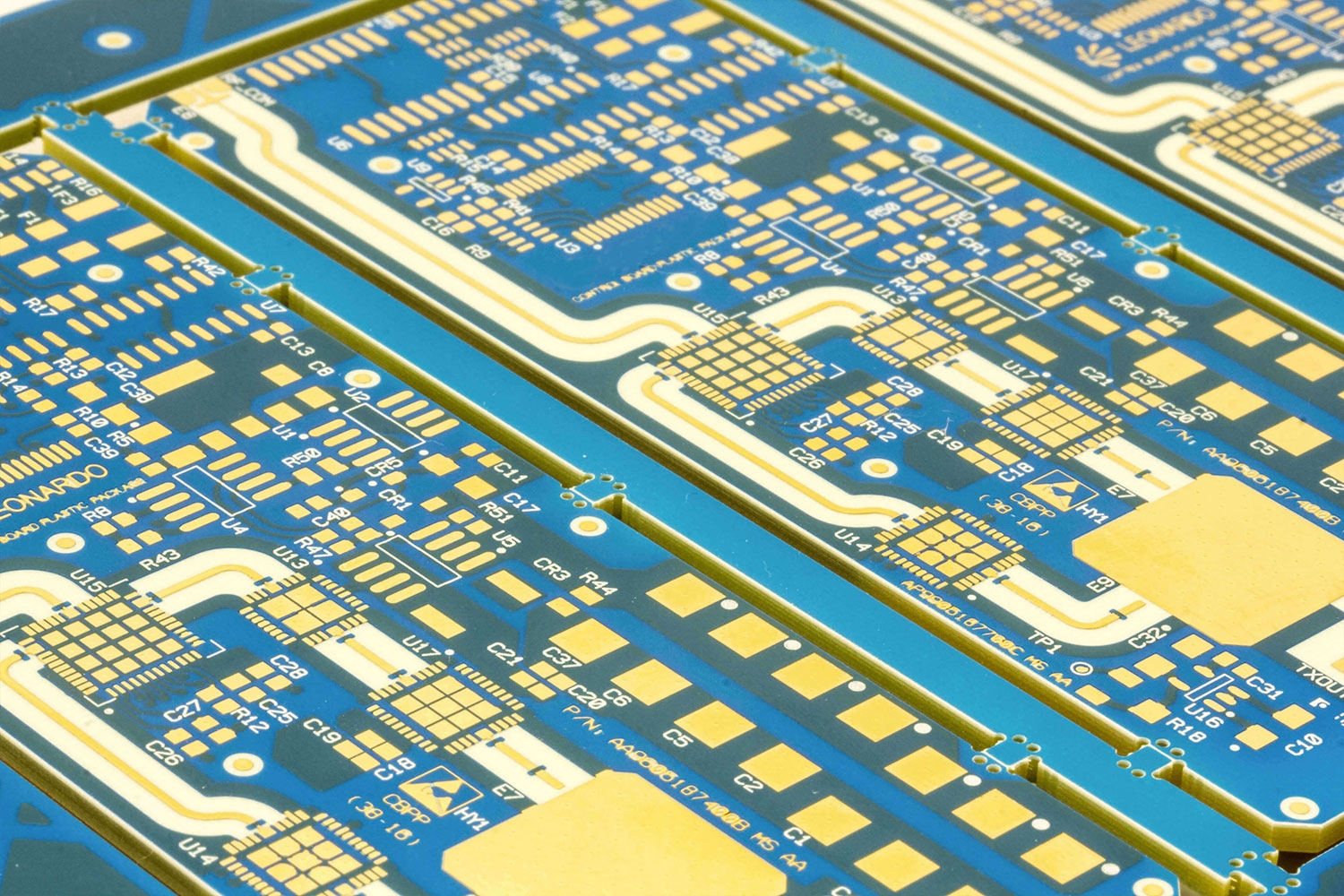

High-frequency ultrasound systems operating from 20 MHz to 100 MHz and above demand PCB laminates with ultra-low dielectric loss, stable dielectric constant (Dk), and minimal signal dispersion. Transducer matching layers, transmit/receive beamformers, and high-channel-count analog front-ends all suffer performance degradation when standard FR-4 introduces excessive insertion loss and phase distortion at these frequencies.

Why FR-4 Fails Above 20 MHz in Ultrasound Systems

Standard FR-4 exhibits a dissipation factor (Df) of 0.018–0.025 and FR4 pcb dielectric constant variation up to ±10% across frequency and temperature. At 50 MHz, a 150 mm trace on FR-4 can introduce 3–6 dB insertion loss and significant group delay variation, destroying image resolution and penetration depth.

High-frequency ultrasound requires:

- Df ≤ 0.004 (preferably ≤ 0.002) at 10 GHz test condition

- Dk tolerance ≤ ±2% across 1 MHz–100 MHz

- Low water absorption (<0.1%) to prevent Dk drift in humid environments

- Smooth copper (RMS ≤ 0.5 µm) to reduce conductor loss

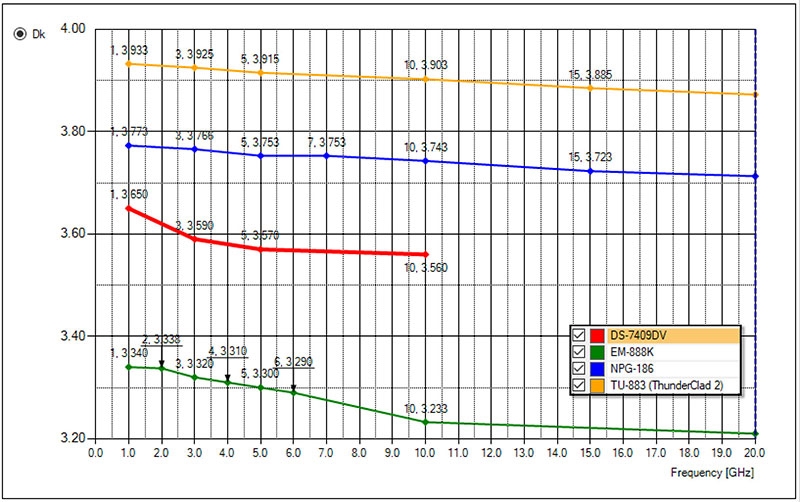

Key Electrical Parameters for Ultrasound PCB Laminates

| Parameter | FR-4 Typical | Required for >30 MHz Ultrasound | Rogers RO4350B | Rogers RO4835 | Panasonic Megtron 6 |

|---|---|---|---|---|---|

| Dk @ 10 GHz | 4.0–4.6 | 3.0–3.8 | 3.48 ±0.05 | 3.50 ±0.05 | 3.3–3.6 |

| Df @ 10 GHz | 0.018–0.025 | ≤0.004 | 0.0037 | 0.0035 | 0.002 |

| Dk Stability 1–100 MHz | Poor | Excellent | Excellent | Excellent | Superior |

| Water Absorption | 0.2–0.5% | <0.1% | 0.06% | 0.05% | 0.08% |

Low-Loss Laminate Families Proven in Ultrasound

Hydrocarbon/Ceramic Composites

- RO4000® series (RO4350B, RO4450F prepreg) remains the most common choice for 30–70 MHz beamformers due to Dk 3.48, Df 0.0037, and excellent processability similar to FR-4.

PTFE-Based Materials

- RT/duroid® 5880/5870 used in research-grade 80–100 MHz systems when minimum loss is critical. Df 0.0009, but requires specialized fabrication.

High-Performance Epoxy/PPE Blends

- Megtron 6/7 and Tachyon 100G offer Df ≤0.002 and superior thermal reliability (Td >400 °C) for 128–256 channel systems.

LCP (Liquid Crystal Polymer)

Emerging choice for pure 50–100 MHz single-layer flexible arrays. Df 0.002, extremely low moisture absorption, and near-hermetic performance.

Suggested Reading: Material Matters: Selecting the Best Laminates for High-Frequency Multilayer PCBs

Signal Integrity Considerations at Ultrasound Frequencies

Transmission Line Loss Breakdown at 50 MHz

For a 100 mm microstrip on 0.254 mm thick laminate:

| Material | Dielectric Loss | Conductor Loss (RMS 0.8 µm) | Total Loss |

|---|---|---|---|

| FR-4 | 4.2 dB | 1.1 dB | ~5.3 dB |

| RO4350B | 0.9 dB | 1.0 dB | ~1.9 dB |

| Megtron 6 | 0.5 dB | 0.9 dB | ~1.4 dB |

Impedance Stability

Ultrasound beamformers require 50 Ω ±3% lines over temperature. RO4000 series maintains Dk within ±0.05 across −40 °C to +120 °C, while FR-4 drifts ±0.3 or more.

Practical Design Guidelines for High-Frequency Ultrasound PCBs

- Use low-profile (LP) or very-low-profile (VLP) copper foil to reduce skin-effect loss

- Specify reverse-treat foil (RTF) or HVLP with RMS roughness ≤0.5 µm

- Keep dielectric thickness ≤0.254 mm (10 mil) for 50–70 MHz boards

- Avoid glass stop in weave-reinforced laminates directly under critical traces

- Use RO4450F or 2929 bondply for multilayer PCB construction (Dk-matched prepreg)

- Maintain symmetric stack-up to prevent warpage during lead-free assembly

Thermal and Mechanical Reliability

High-channel-count probes undergo 260 °C reflow and 1000+ cycles −20 °C to +80 °C. RO4835 and Megtron 7 incorporate oxidized ceramic fillers for improved time-to-delamination and CAF resistance compared to earlier low-loss materials.

Conclusion

Successful high-frequency ultrasound systems above 30 MHz require replacement of FR-4 with dedicated low-loss laminates. RO4350B/RO4450F remains the most cost-effective and widely supported choice for 30–70 MHz commercial probes. Systems targeting 80–100 MHz or 256+ channels increasingly adopt Megtron 6/7 or LCP to achieve the required signal fidelity and dynamic range.

FAQs

Q1: Can FR-4 ever be used in high-frequency ultrasound PCBs above 30 MHz?

A1: No. FR-4 dissipation factor above 0.018 introduces 3–8 dB excess loss on typical trace lengths, severely degrading signal-to-noise ratio and imaging depth.

Q2: What is the most common low-loss PCB material for 50 MHz ultrasound beamformers?

A2: RO4350B with RO4450F prepreg dominates commercial 32–128 channel systems due to stable Dk 3.48, Df 0.0037, and processing nearly identical to FR-4.

Q3: How much does switching to a low Df PCB improve ultrasound image quality?

A3: Reducing Df from 0.020 (FR-4) to 0.003 reduces round-trip insertion loss by 4–6 dB, increasing penetration depth by 15–30% and improving axial resolution through lower phase noise.

Q4: Are PTFE materials required for 100 MHz ultrasound applications?

A4: Not mandatory. Modern hydrocarbon (Megtron 7) and LCP laminates with Df ≤0.002 now deliver comparable loss at lower cost and easier fabrication than PTFE composites.

References

IPC-4101E — Specification for Base Materials for Rigid and Multilayer Printed Boards. IPC, 2017.

IPC-TM-650 2.5.5.9 — Permittivity and Loss Tangent, Parallel Plate Method. IPC, current version.

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

Rogers Corporation — RO4000® Series Data Sheet (Dk/Df test conditions per IPC-TM-650 2.5.5.5).

Panasonic Corporation — Megtron 6/7 Technical Literature (measured at 10 GHz).