Introduction

Surface Mount Technology (SMT) has transformed the electronics industry by enabling the production of compact, high-performance devices. At the heart of SMT lies the PCB assembly process, where precision and reliability are paramount. SMT testing plays a critical role in ensuring that assembled printed circuit boards meet stringent quality standards. For electrical engineers, understanding SMT testing methods is essential to identify SMT defects, verify component integrity, and maintain product reliability. This article explores the intricacies of SMT testing within the PCB assembly process. It covers the technical principles, common testing methods, practical approaches to address defects, and the relevance of industry standards. By delving into these aspects, engineers can enhance their knowledge of PCB testing and apply best practices to achieve defect-free assemblies.

Related Reading: Mastering PCB Assembly: A Comprehensive Guide to Surface Mount Technology

What Is SMT Testing and Why It Matters

SMT testing refers to a series of evaluation methods used during and after the SMT PCB assembly process to verify the quality and functionality of the board. These tests focus on detecting SMT defects such as misaligned components, soldering issues, or electrical failures. They also ensure component integrity by confirming that each part operates as intended under specified conditions. For electrical engineers, SMT testing is vital because even minor defects can lead to system failures, costly rework, or product recalls. With the increasing complexity of electronic devices, the demand for robust PCB testing has grown. Effective testing not only prevents failures but also upholds reliability in applications ranging from consumer electronics to aerospace systems. By identifying issues early, SMT testing saves time and resources while ensuring compliance with industry benchmarks.

Technical Principles of SMT Testing

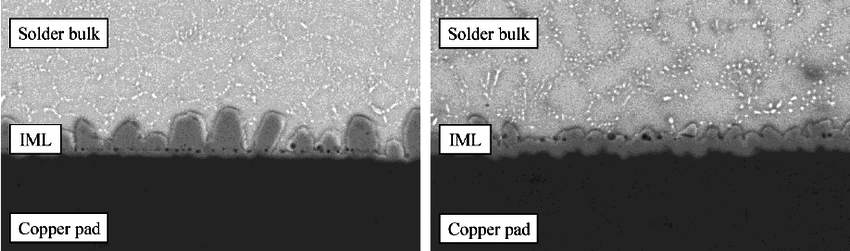

SMT testing operates on the principle of validating both the physical and electrical characteristics of a PCB after assembly. The primary goal is to detect defects that could compromise performance. These defects often include solder joint failures, component misalignment, or insufficient electrical connectivity. Testing methods are designed to assess different aspects of the assembly process. For instance, visual inspections focus on surface-level issues, while electrical tests verify circuit functionality. Industry standards such as IPC-A-610H, which defines acceptability criteria for electronic assemblies, guide these evaluations. Another key principle is the correlation between testing and design for testability (DFT). Boards designed with accessible test points facilitate more accurate and efficient PCB testing. Understanding these principles helps engineers select the appropriate testing method for specific assembly challenges.

Common SMT Defects and Their Causes

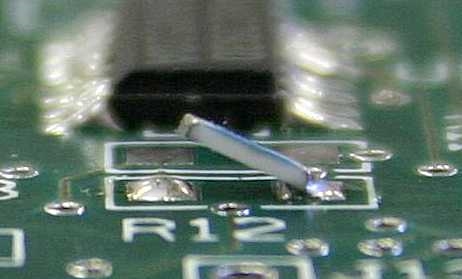

Several types of SMT defects can occur during the assembly process. Tombstoning, where a component stands upright due to uneven soldering, often results from improper pad design or reflow profiles. Bridging, another defect, happens when solder connects adjacent pads, typically due to excessive solder paste or incorrect stencil alignment. Component misalignment may stem from pick-and-place machine errors or substrate warpage. These issues compromise component integrity and can lead to short circuits or open connections. Electrical defects, such as insufficient contact, might arise from poor solder wetting or contamination on the board surface. Identifying the root causes of these SMT defects through systematic testing is crucial for maintaining assembly quality.

Key Testing Methods in SMT Assembly

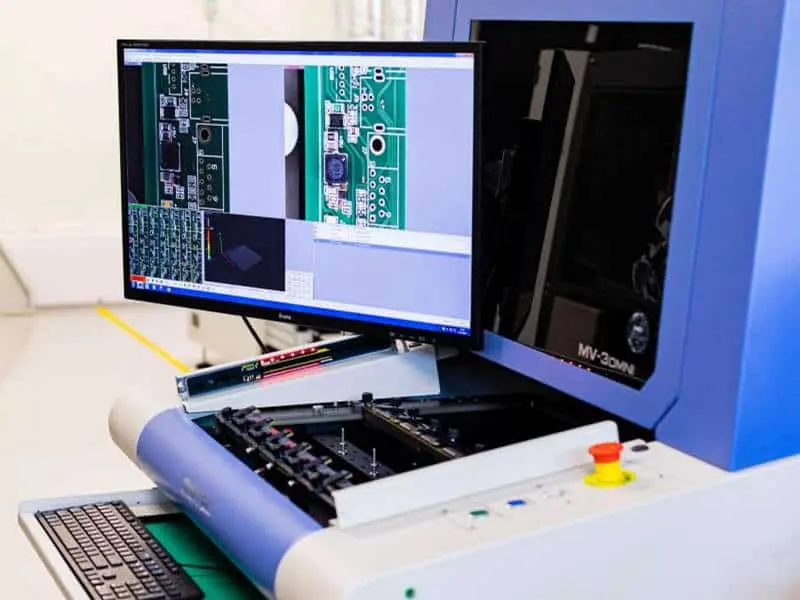

Several testing methods are employed to ensure the quality of SMT assemblies. Automated Optical Inspection (AOI) uses cameras to detect visual defects like misalignment or missing components. X-ray inspection is utilized for non-visible issues, such as voids in solder joints under components like Ball Grid Arrays (BGAs). In-Circuit Testing (ICT) evaluates electrical performance by checking for shorts, opens, and component values through test probes. Functional testing simulates real-world operating conditions to confirm overall board performance. Each method targets specific aspects of PCB testing, ensuring comprehensive defect detection. Standards like IPC-TM-650 provide guidelines for test procedures, ensuring consistency across different assembly environments. Engineers must choose the appropriate method based on the board’s complexity and application requirements.

Related Reading: Selecting the Right PCB Inspection Equipment: A Guide to AOI, X Ray, and Flying Probe Testing

Practical Solutions for Effective SMT Testing Process

Implementing effective SMT testing requires a combination of advanced tools, standardized processes, and proactive defect prevention. Electrical engineers can adopt several best practices to enhance PCB testing outcomes. First, integrating Design for Testability (DFT) principles during the design phase ensures that boards are easier to test. This includes placing test pads strategically for ICT access. Second, selecting the right testing method for each stage of assembly minimizes oversight. For example, AOI can be used post-placement to catch early SMT defects, while ICT is ideal after soldering to verify electrical connections. Third, maintaining equipment calibration and adhering to standards like IPC-A-610H ensures accurate results. Regular operator training also reduces human error during testing.

Addressing Common SMT Defects

To tackle SMT defects, engineers must focus on both prevention and correction. For tombstoning, optimizing reflow oven profiles and ensuring balanced pad designs can mitigate risks. Bridging can be minimized by refining stencil apertures and controlling solder paste volume. Component misalignment often requires recalibrating pick-and-place machines or inspecting for board warpage before assembly. Post-detection, rework processes guided by IPC-7711/7721C standards help repair defects without damaging the board. Documenting defect patterns also aids in identifying recurring issues, enabling process adjustments. By combining preventive measures with systematic troubleshooting, engineers can maintain component integrity and reduce failure rates.

Related Reading: Prevent SMT Soldering Defects: Tips

Importance of Industry Standards in SMT Testing Process

Adherence to industry standards is non-negotiable for reliable SMT testing. Standards such as IPC-A-610H provide detailed criteria for acceptable solder joints and component placement. IPC-TM-650 offers test methods for evaluating board materials and assembly processes. Following these guidelines ensures consistency in detecting SMT defects and verifying component integrity. Additionally, standards like JEDEC J-STD-020E classify moisture sensitivity levels for components, aiding in proper handling during testing. Compliance not only enhances product quality but also builds trust in the assembly process. Engineers must stay updated on revisions to these standards to align testing practices with the latest industry expectations.

Troubleshooting Insights for SMT Testing Challenges

In real-world scenarios, SMT testing can present unique challenges. One common issue is false positives during AOI, where acceptable variations are flagged as defects. This can be resolved by fine-tuning inspection parameters or cross-verifying with manual inspection. Another challenge is testing high-density boards with limited test point access. In such cases, combining ICT with functional testing can provide a more comprehensive assessment. For BGAs, X-ray inspection is indispensable to detect hidden solder voids, but interpreting results requires expertise. Engineers should also watch for environmental factors like humidity, which can affect test accuracy. Following guidelines from IPC-TM-650 for environmental testing conditions helps mitigate such issues. These troubleshooting strategies ensure that PCB testing remains effective even in complex scenarios.

Conclusion

SMT testing is a cornerstone of the SMT PCB assembly process, ensuring that electronic products meet the highest standards of quality and reliability. By understanding the technical principles behind PCB testing, electrical engineers can identify and address SMT defects effectively. Implementing practical solutions, adhering to industry standards like IPC-A-610H, and applying troubleshooting insights enhance the integrity of components and the overall assembly. As electronics continue to evolve, staying informed about testing methods and best practices remains essential. Through systematic approaches to SMT testing, engineers can deliver robust, defect-free PCBs that power modern technology across diverse applications.

FAQs

Q1: What are the most common SMT defects identified during PCB testing?

A1: SMT defects often include tombstoning, solder bridging, and component misalignment. These issues can arise from uneven soldering, excessive solder paste, or equipment errors. Identifying them early through PCB testing methods like AOI or X-ray inspection is crucial. Following standards such as IPC-A-610H ensures consistent defect detection and helps maintain assembly quality.

Q2: How does SMT testing ensure component integrity in assemblies?

A2: SMT testing verifies component integrity by checking physical placement and electrical performance. Methods like In-Circuit Testing (ICT) confirm proper connections, while functional testing simulates real-world conditions. Adhering to standards like JEDEC J-STD-020E for component handling prevents damage during testing. This comprehensive approach ensures components function reliably in the final product.

Q3: Which SMT testing method is best for detecting hidden defects?

A3: X-ray inspection is ideal for detecting hidden SMT defects, such as solder voids under components like BGAs. Unlike visual methods, it reveals internal issues without disassembly. Guided by standards like IPC-TM-650, this technique ensures accurate identification of flaws. Engineers often combine it with other tests for thorough validation.

Q4: Why are industry standards important for SMT testing processes?

A4: Industry standards like IPC-A-610H provide clear criteria for acceptable assemblies, ensuring consistent SMT testing outcomes. They guide defect detection, test methods, and component handling. Compliance minimizes errors and enhances product reliability. For engineers, following these benchmarks is essential to meet quality expectations and maintain trust in the assembly process.

References

IPC-A-610H — Acceptability of Electronic Assemblies. IPC, 2021.

IPC-TM-650 — Test Methods Manual. IPC, Current Version.

IPC-7711/7721C — Rework, Modification and Repair of Electronic Assemblies. IPC, 2021.

JEDEC J-STD-020E — Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices. JEDEC, 2014.