Introduction

Matte solder mask adhesion plays a critical role in the reliability and longevity of printed circuit boards. As a protective layer applied over copper traces, solder mask prevents short circuits, oxidation, and unintended solder bridges during assembly. For electrical engineers, understanding the factors influencing adhesion, such as substrate material, surface preparation, coating methods, curing process, and environmental factors, is essential for designing robust circuit boards. Poor adhesion can lead to delamination, reduced insulation, and potential failures in harsh operating conditions. This article dives deep into the technical aspects of achieving strong matte solder mask adhesion, offering practical insights and best practices aligned with industry standards. Whether you are optimizing a design or troubleshooting a manufacturing issue, this guide provides a comprehensive look at ensuring durability and performance.

What Is Matte Solder Mask and Why Adhesion Matters

Solder mask is a thin polymer layer applied to printed circuit boards to insulate copper traces and define solderable areas. Matte solder mask, distinguished by its non-reflective finish, is often preferred for applications requiring reduced glare, such as in inspection processes or high-density designs. Its adhesion to the substrate material directly impacts the board’s ability to withstand mechanical stress, thermal cycles, and environmental exposure. Strong adhesion prevents peeling or cracking, which could expose copper and lead to electrical failures. For engineers, ensuring reliable adhesion is not just about meeting specifications but also about guaranteeing performance in real-world conditions. Adhesion issues can compromise the integrity of the circuit board, making it a priority in both design and manufacturing stages.

Technical Principles of Matte Solder Mask Adhesion

Adhesion of matte solder mask to a circuit board substrate involves complex interactions between chemical bonding, mechanical interlocking, and surface properties. Several key factors influence this process.

Substrate Material Compatibility

The choice of substrate material significantly affects adhesion. Common materials like FR-4, composed of woven fiberglass and epoxy resin, provide a stable base due to their surface texture and chemical composition. However, alternative substrates such as polyimide or metal-core boards may present challenges due to smoother surfaces or differing thermal expansion properties. The solder mask must form a strong bond with the substrate to resist delamination during thermal stress or mechanical handling. Compatibility between the mask’s polymer formulation and the substrate’s surface chemistry is crucial for long-term reliability.

Related Reading: Material Matters: Selecting the Best Laminates for High-Frequency Multilayer PCBs

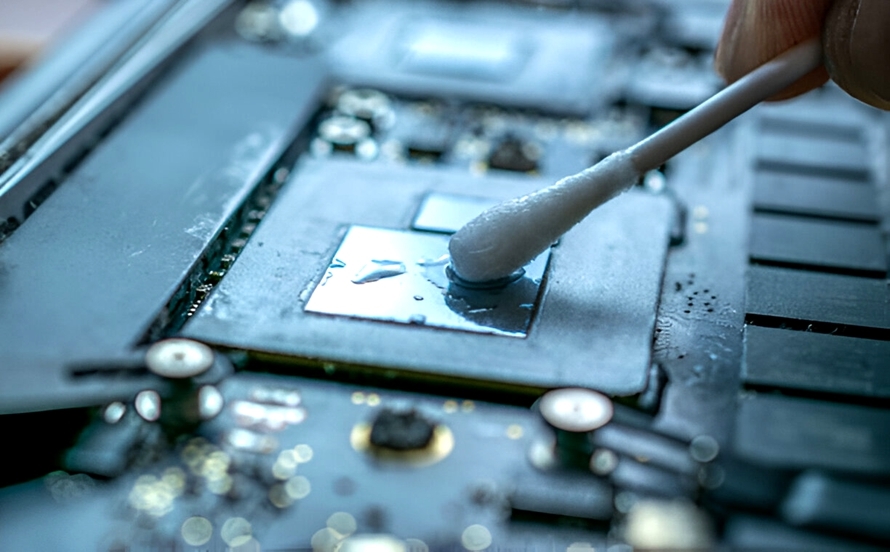

Surface Preparation Techniques

Surface preparation is a foundational step for achieving optimal adhesion. Any contamination, such as oils, dust, or oxide layers on the copper or substrate, can weaken the bond. Cleaning processes often involve chemical etching or micro-abrasion to enhance surface roughness, creating a better mechanical interlock for the solder mask. Proper preparation ensures that the mask adheres uniformly without voids or weak spots. Standards like IPC-A-600K provide guidelines for acceptable surface conditions prior to coating, emphasizing the importance of cleanliness and texture.

Coating Methods and Their Impact

The method used to apply the matte solder mask influences adhesion quality. Common techniques include screen printing for simpler designs, spray coating for complex multilayer boards, and curtain coating for high-volume production. Each method affects the thickness and uniformity of the layer, which in turn impacts how well the mask bonds to the substrate. Spray coating, for instance, can achieve consistent coverage on intricate geometries but requires precise control to avoid overspray or uneven layers. Uniform application is essential to prevent stress points that could lead to adhesion failure.

Related Reading: Dip vs. Spray: Selecting the Best Conformal Coating Machine for Your Application

Curing Process and Adhesion Strength

The curing process solidifies the solder mask and establishes its bond with the substrate. Most matte solder masks are cured using heat or ultraviolet light, depending on the formulation. Thermal curing, often guided by specifications in IPC-6012E, involves controlled temperature profiles to ensure complete polymerization without introducing internal stresses. Insufficient curing can result in a weak bond, while over-curing may cause brittleness, increasing the risk of cracking. Engineers must monitor curing parameters closely to achieve optimal adhesion and durability.

Environmental Factors Affecting Adhesion

Environmental factors during manufacturing and operation play a significant role in adhesion performance. High humidity can introduce moisture, weakening the bond between the mask and substrate. Temperature fluctuations may cause thermal expansion mismatches, leading to stress at the interface. Additionally, exposure to chemicals or solvents in certain applications can degrade the polymer layer if not formulated for resistance. Standards such as IPC-TM-650 provide test methods to evaluate adhesion under various environmental conditions, helping engineers predict long-term behavior.

Best Practices for Optimizing Matte Solder Mask Adhesion

Achieving strong adhesion requires a systematic approach across design, material selection, and manufacturing processes. Below are actionable strategies for electrical engineers to ensure reliable performance.

Selecting the Right Substrate Material

Evaluate the substrate material based on the application’s thermal, mechanical, and electrical requirements. For standard designs, FR-4 offers a balance of cost and adhesion properties. For high-frequency or high-temperature applications, consider materials with compatible surface characteristics and consult material datasheets for solder mask compatibility. Ensure that the chosen substrate aligns with the environmental demands of the end use.

Implementing Rigorous Surface Preparation

Adopt strict surface preparation protocols to eliminate contaminants and enhance bonding. Use chemical cleaners or plasma treatment to remove organic residues and oxides. Micro-etching can increase surface roughness for better mechanical adhesion. Regularly inspect surfaces for cleanliness and uniformity, following guidelines outlined in IPC-A-600K, to minimize risks of poor bonding.

Choosing Appropriate Coating Methods

Select a coating method suited to the board’s complexity and production volume. For intricate designs, spray coating ensures even distribution over fine features. For simpler boards, screen printing offers cost-effective coverage. Monitor application parameters to maintain consistent thickness, as uneven layers can create weak adhesion zones. Test different methods during prototyping to identify the most effective approach.

Controlling the Curing Process

Optimize the curing process by adhering to recommended temperature and time profiles. Use precise equipment to avoid under or over-curing, which can compromise adhesion strength. Thermal curing often requires gradual temperature ramps to prevent stress buildup. Refer to IPC-6012E for performance specifications related to curing and ensure consistent monitoring during production.

Mitigating Environmental Factors

Account for environmental factors during both manufacturing and application. Store materials in controlled conditions to prevent moisture absorption before coating. Test adhesion under simulated environmental stresses using methods from IPC-TM-650 to validate performance. Design with margins for thermal expansion and chemical exposure to reduce risks of delamination in harsh environments.

Troubleshooting Common Adhesion Issues

Adhesion failures can manifest as peeling, blistering, or cracking of the matte solder mask. Identifying the root cause requires a systematic approach. If delamination occurs near edges, inspect for inadequate surface preparation or contamination. Blistering often indicates trapped moisture or insufficient curing, necessitating a review of storage conditions and curing profiles. Cracking may result from thermal stress or material mismatch, suggesting a need to reassess substrate selection or environmental exposure limits. Conduct adhesion tests, such as tape or cross-hatch methods described in IPC-TM-650, to quantify bond strength and pinpoint weaknesses. Addressing these issues early in the design or manufacturing phase prevents costly failures in the field.

Conclusion

Matte solder mask adhesion is a cornerstone of printed circuit board reliability, directly influencing performance and durability. By understanding the interplay of substrate material, surface preparation, coating methods, curing process, and environmental factors, electrical engineers can design and manufacture circuit boards that withstand demanding conditions. Implementing best practices, from rigorous surface cleaning to controlled curing, ensures a strong bond that resists delamination and environmental stress. Adherence to industry standards provides a framework for consistent quality. With careful attention to these elements, engineers can mitigate risks and achieve long-lasting protection for critical copper traces.

FAQs

Q1: How does substrate material impact matte solder mask adhesion?

A1: Substrate material significantly affects adhesion due to differences in surface texture and chemical properties. Materials like FR-4 offer good bonding with most solder masks due to their rough surface. Smoother substrates, such as polyimide, may require additional surface treatments to enhance mechanical interlocking. Selecting a compatible material is key to preventing delamination under thermal or mechanical stress.

Q2: What surface preparation techniques improve solder mask adhesion on circuit boards?

A2: Surface preparation is critical for adhesion. Techniques like chemical cleaning remove contaminants, while micro-etching increases surface roughness for better bonding. Plasma treatment can also enhance surface energy for stronger chemical bonds. Following standards like IPC-A-600K ensures cleanliness and uniformity, reducing the risk of weak spots in the solder mask layer.

Q3: Why is the curing process important for solder mask adhesion?

A3: The curing process solidifies the solder mask, establishing its bond with the substrate. Proper curing, whether thermal or UV based, ensures complete polymerization without stress or brittleness. Inadequate curing leads to weak adhesion, while over-curing can cause cracking. Adhering to specifications in IPC-6012E helps achieve optimal strength and durability.

Q4: How do environmental factors affect solder mask adhesion over time?

A4: Environmental factors like humidity, temperature fluctuations, and chemical exposure can degrade adhesion. Moisture weakens bonds, thermal cycles induce stress, and chemicals may erode the mask. Testing under conditions outlined in IPC-TM-650 helps predict performance. Designing with these factors in mind ensures the circuit board remains reliable in harsh environments.

References

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-TM-650 — Test Methods Manual. IPC, various dates.