Introduction

For electrical engineers and procurement teams, budgeting for printed circuit board (PCB) projects is a critical step in product development. Estimating costs accurately ensures projects stay on track without unexpected expenses. Tools like PCB cost calculators, online PCB quotes, and PCB pricing tools have become popular for providing quick PCB price estimations. However, a key question remains: how reliable are these tools for creating a solid PCB manufacturing budget? This article explores the accuracy of these digital solutions by examining their underlying mechanisms, limitations, and practical use in real-world scenarios. Written from a manufacturing specialist's perspective, this piece aims to equip engineers with the knowledge to use these tools effectively while understanding their potential pitfalls. Let’s dive into the factors that influence the precision of PCB cost calculators.

What Are PCB Cost Calculators and Why Do They Matter?

PCB cost calculators are digital platforms or software designed to estimate the expenses associated with PCB fabrication and assembly. These tools typically allow users to input parameters such as board dimensions, layer count, material type, and quantity to generate a rough PCB price estimation. Their primary purpose is to streamline the budgeting process, saving time for engineers who would otherwise need to request manual quotes from suppliers. For electrical engineers, having a reliable PCB pricing tool is essential for early-stage project planning and cost optimization. In an industry where margins can be tight, miscalculations can lead to delays or budget overruns. Understanding the capabilities and limitations of online PCB quotes helps teams make informed decisions, ensuring that initial estimates align closely with final costs during production.

Technical Principles Behind PCB Cost Calculators

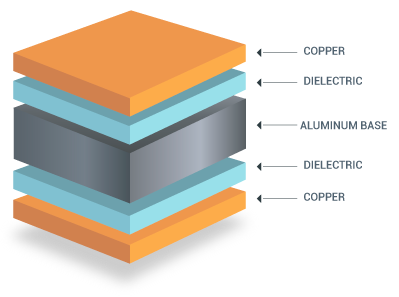

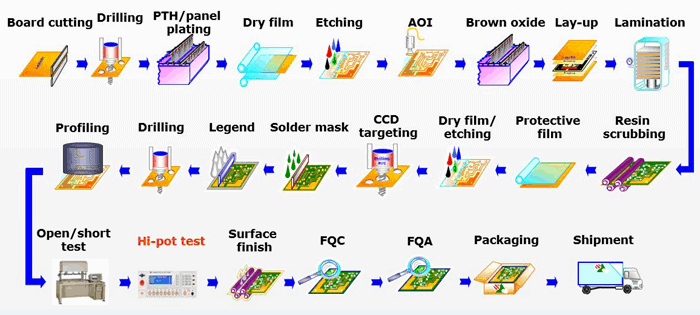

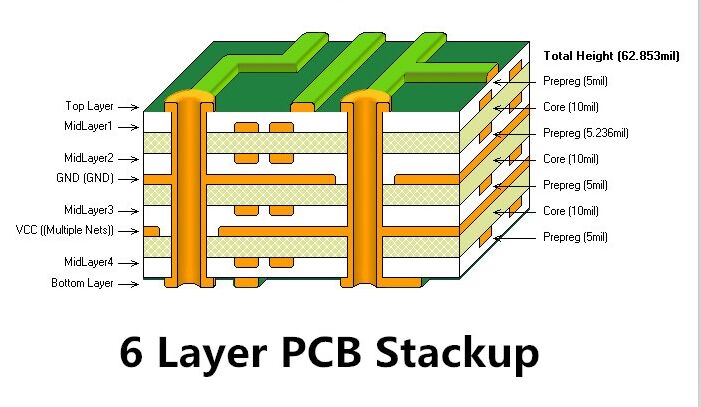

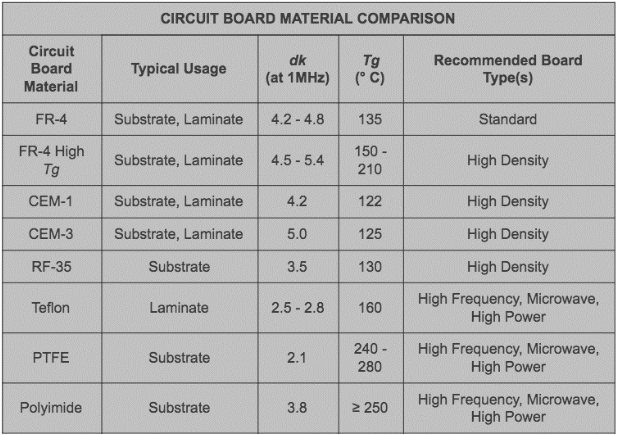

The functionality of a PCB cost calculator relies on predefined algorithms that factor in various manufacturing variables. These tools often consider elements aligned with industry standards such as those outlined in IPC-6012E, which specifies performance requirements for rigid printed boards. Common inputs include board size, number of layers, and surface finish options. Material choices, like standard FR-4 or high-frequency laminates, also play a significant role in cost determination. Additionally, production volume impacts pricing due to economies of scale, while turnaround time can introduce rush fees.

However, the accuracy of these tools depends on the complexity of their algorithms and the data they use. Many calculators simplify calculations by assuming standard manufacturing conditions, which may not account for specialized processes or unique design requirements. For instance, features like blind vias or controlled impedance, often critical in high-speed designs, may not be accurately reflected in basic PCB pricing tools. Without transparency into the tool’s logic, engineers might receive an online PCB quote that deviates from actual costs when non-standard specifications are involved.

Factors Affecting the Accuracy of PCB Price Estimation

Several elements influence how close a PCB cost calculator’s estimate is to the final manufacturing expense. Below are key factors electrical engineers should consider when using these tools for PCB manufacturing budget planning.

-

Design Complexity: Simple two-layer boards are easier to estimate than multilayer designs with advanced features. Tools may struggle to price intricate requirements like high-density interconnects (HDI) if not explicitly programmed for such cases.

-

Material Selection: Standard materials are often well-accounted for, but specialty substrates or thicknesses outside typical ranges can skew estimates. Referencing standards like IPC-A-600K for material acceptability can help engineers align their inputs with common practices.

-

Production Volume: Low-volume orders often carry higher per-unit costs due to setup fees, while high-volume runs benefit from cost reductions. Not all PCB pricing tools adjust dynamically for these variations.

-

Lead Time: Expedited production increases costs, but some calculators might use fixed multipliers that don’t reflect real-time factory scheduling constraints.

Suggested Reading: PCB online calculators and the accuracy in determining manufacturing time

-

Additional Services: Processes like testing, conformal coating, or panelization may not be included in basic online PCB quotes, leading to discrepancies.

Understanding these variables helps engineers interpret the outputs of a PCB cost calculator with a critical eye, ensuring they account for potential gaps in the estimation process.

Limitations of Online PCB Quotes

While online PCB quotes offer convenience, they come with inherent limitations that can affect their reliability. First, many tools lack customization for niche or complex designs. They often operate on generalized assumptions, which might not cover specific requirements like those for high-reliability applications under IPC-6012E guidelines. Second, cost calculators may not update frequently to reflect fluctuating raw material prices or labor rates, leading to outdated PCB price estimations. Third, hidden costs such as shipping, customs duties, or tooling fees are frequently excluded from initial quotes, creating a gap between estimated and actual expenses.

Another concern is the lack of human oversight. Automated PCB pricing tools cannot replicate the expertise of a manufacturing engineer who can spot potential design issues or suggest cost-saving optimizations. For critical projects, relying solely on a PCB cost calculator without follow-up verification can result in budget misalignments. Electrical engineers should treat these tools as starting points rather than definitive answers.

Best Practices for Using PCB Cost Calculators Effectively

To maximize the accuracy of a PCB manufacturing budget, engineers can follow these practical steps when using PCB pricing tools. These guidelines ensure that estimates are as close to reality as possible.

-

Provide Detailed Inputs: Enter precise specifications for board dimensions, layer count, and finishes. Incomplete data leads to unreliable online PCB quotes.

-

Cross-Reference Standards: Align design parameters with recognized guidelines like IPC-A-600K to ensure inputs match typical manufacturing capabilities.

-

Account for Extras: Manually add potential costs for testing, packaging, or expedited shipping if the tool excludes them.

-

Use Multiple Tools: Compare estimates from different PCB cost calculators to identify outliers or consistent pricing trends.

-

Verify with Manual Quotes: For critical projects, request a detailed quote from manufacturing experts to confirm the tool’s PCB price estimation.

By combining these practices with a thorough understanding of design requirements, engineers can mitigate the risk of cost discrepancies and build a more accurate PCB manufacturing budget.

Related Reading: PCB Component Cost Calculators: A Comprehensive Guide to Estimating Your Project Budget

Real-World Insight: Balancing Tools and Expertise

From a manufacturing specialist’s viewpoint, PCB cost calculators serve as valuable aids but cannot replace human expertise. In my experience, these tools work best for straightforward designs with standard specifications. For instance, a simple two-layer board for a consumer product often yields estimates within a reasonable range of final costs. However, when dealing with advanced designs, such as those for aerospace applications requiring strict adherence to IPC-6012E, automated tools frequently fall short. I’ve seen cases where engineers relied solely on a PCB pricing tool, only to face significant cost adjustments later due to unaccounted special processes.

The solution lies in a hybrid approach. Use a PCB cost calculator for initial budgeting, but always follow up with detailed discussions during the design review phase. This ensures that unique requirements are captured, and the PCB manufacturing budget reflects the true scope of the project. Collaboration between design teams and manufacturing experts remains essential for precision.

Conclusion

PCB cost calculators offer a convenient way to estimate expenses for electrical engineers planning their projects. While these tools provide quick PCB price estimations and online PCB quotes, their accuracy depends on design complexity, input quality, and the tool’s underlying algorithms. Limitations such as outdated data, hidden costs, and lack of customization highlight the need for caution when relying on a PCB pricing tool. By following best practices and combining digital estimates with expert input, engineers can create a reliable PCB manufacturing budget. Ultimately, these calculators are most effective as starting points, guiding teams toward informed decisions while navigating the intricacies of PCB production costs.

FAQs

Q1: How reliable is a PCB cost calculator for complex multilayer designs?

A1: A PCB cost calculator often struggles with complex multilayer designs due to unique features like blind vias or HDI requirements. While useful for basic estimates, these tools may not account for specialized processes. Electrical engineers should use them as a starting point and verify costs with manufacturing experts to ensure accuracy for intricate projects under standards like IPC-6012E.

Q2: What factors can skew an online PCB quote for budget planning?

A2: An online PCB quote can be skewed by incomplete inputs, outdated material pricing, or unaccounted costs like shipping and testing. Design complexities or rush orders may also not be fully captured. Engineers must provide detailed specifications and cross-check estimates to build a realistic PCB manufacturing budget for their projects.

Q3: How can I improve the accuracy of PCB price estimation tools?

A3: To improve PCB price estimation accuracy, input precise design details such as layer count and materials. Reference standards like IPC-A-600K for typical specifications. Compare multiple tools and manually add potential extra costs. Finally, validate the estimate with a manual quote for critical projects to ensure a dependable budget plan.

Q4: Are PCB pricing tools suitable for high-volume production estimates?

A4: PCB pricing tools can provide a rough estimate for high-volume production by factoring in economies of scale. However, they might not reflect real-time factory constraints or bulk discounts accurately. For a precise PCB manufacturing budget, engineers should use these tools initially and confirm pricing with detailed manufacturing input for large orders.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.