Why Are Specific Test Probes Essential for SMT PCB Testing?

The Role of Probes in Functional Testing

Functional testing of Surface Mount Technology (SMT) Printed Circuit Boards (PCBs) is critical to verify that assembled boards operate as intended under various conditions. Test probes serve as the indispensable interface, establishing direct electrical contact between the test equipment and the PCB's test points. They facilitate precise measurements of electrical signals, confirm continuity, and assess overall functionality. Opting for unsuitable probes can lead to inaccurate data, damage to delicate components, or even complete test failures. Therefore, meticulous PCB test probe selection is paramount for consistent and dependable results.

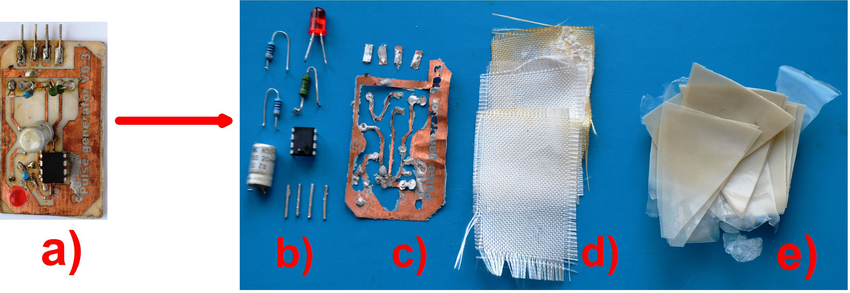

Addressing Challenges in SMT Designs

SMT designs inherently feature smaller, more densely packed components compared to traditional through-hole technology. This density often translates into minute and closely spaced test points, necessitating high-precision instruments like fine pitch probes. A thorough understanding of probe selection nuances and diligent maintenance practices is key to effectively navigating these challenges and ensuring the integrity of your testing process.

Related Reading: SMT Testing in SMT PCB Assembly Process

What Key Factors Influence PCB Test Probe Selection?

Matching Probe to PCB Test Point Size

A primary consideration in choosing PCB test probes is ensuring compatibility with the dimensions of your board's test points. Many SMT PCBs, especially those with high-density layouts, feature test points as small as 0.5 mm or even less in diameter. Using a probe that is too large risks poor contact, misalignment, or damage to both the test point and surrounding components. It's crucial to consult your board's design specifications and select a probe tip with a diameter that is slightly smaller than or equal to the test point for a secure connection without applying excessive force. Spring-loaded probe tips are particularly beneficial as they provide consistent pressure while protecting delicate pads.

Requirements for Fine Pitch Probes on Dense Boards

As SMT technology evolves, components are positioned increasingly closer, often demanding fine pitch probes for effective testing. "Fine pitch" denotes the minimal spacing between test points or component leads, which can be as narrow as 0.2 mm. Conventional probes typically lack the precision to access these confined areas without risking short circuits or missing the target entirely. Fine pitch probes feature ultra-thin tips specifically designed to navigate tight spaces. When choosing these, align the probe tip diameter with your PCB's pitch; for instance, a 0.5 mm pitch board would require a probe tip of 0.3 mm or less to prevent interference. Additionally, confirm that the probe's material and construction are robust enough to withstand repetitive use in such precise applications without deforming.

Minimizing Test Probe Resistance for Accuracy

Test probe resistance critically impacts the accuracy of functional testing. Unwanted resistance within the probe tip or its contact point can introduce measurement errors in voltage or current, potentially leading to misleading test outcomes. Ideally, probes should exhibit low contact resistance, typically below 50 milliohms, to minimize signal degradation. For SMT PCBs, where signals often involve low voltage and high frequencies, even minor resistance fluctuations can skew results. Look for probes crafted from highly conductive materials such as gold-plated beryllium copper, known for their excellent conductivity and durability. Regular testing and calibration of your probes are also vital to detect any increases in resistance over time due to wear or contamination.

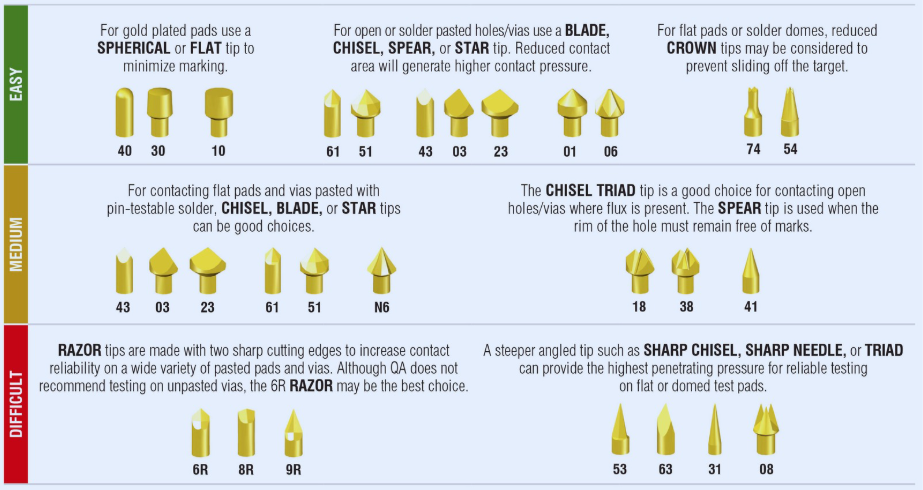

Selecting the Right Probe Tip Style and Shape

The shape and style of a probe tip significantly influence its efficacy during testing. Various SMT PCB designs may necessitate specific tip styles to ensure reliable contact and prevent damage. Common tip configurations include:

● Pointed Tips: Best suited for small test points or vias, offering pinpoint precision for fine pitch applications.

● Chisel Tips: Ideal for larger test pads, providing a broader contact area for enhanced stability.

● Cupped Tips: Engineered to securely grip test points, reducing the likelihood of slippage on smooth surfaces.

Base your tip style selection on the surface characteristics of your PCB and the nature of the test points. For example, a cupped tip might be the optimal choice for flat, smooth pads to prevent slippage during the testing process.

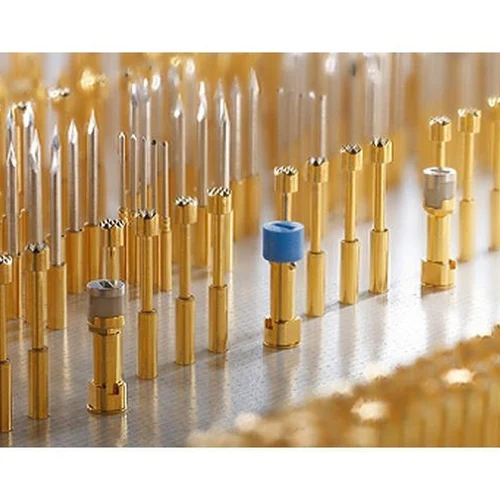

The Importance of Durability and Material Quality

Test probes undergo considerable stress from repeated testing cycles. Opting for probes made from durable materials ensures both longevity and consistent performance. Probes featuring stainless steel bodies and gold-plated tips are favored for their corrosion resistance and superior conductivity. Furthermore, spring-loaded probes should incorporate robust internal mechanisms to maintain consistent contact pressure throughout thousands of cycles. For high-volume testing environments, investing in premium probes can reduce long-term costs by minimizing the need for frequent replacements. Always review manufacturer specifications for cycle life ratings, which indicate the number of test cycles a probe can withstand before performance deteriorates; some high-end probes can exceed 100,000 cycles.

How Does Routine Maintenance Extend Probe Life and Accuracy?

Regular Cleaning to Prevent Contamination

Even top-tier test probes will underperform if neglected. Consistent probe maintenance is crucial for maintaining accuracy and preventing damage to both the probes and the PCBs being tested. Over time, probe tips can accumulate debris, flux residue, or oxidation, which increases contact resistance and compromises measurement reliability. Clean your probes after each testing session using a soft cloth or brush moistened with a mild solvent like isopropyl alcohol. Avoid using abrasive materials that could scratch the delicate tip surface, particularly on gold-plated probes. For persistent residues, specialized probe cleaning tools or pads designed for sensitive electronics are recommended. Regular cleaning not only enhances accuracy but also prevents the transfer of contamination to the PCB, which could lead to shorts or other issues.

Proper Storage for Damage Prevention

Incorrect storage can easily bend or damage probe tips, especially the ultra-thin designs of fine pitch probes. Always store probes in a protective case or holder when not in use, ensuring that the tips are not subjected to pressure or in contact with other objects. Avoid placing heavy items on top of stored probes, as this can deform the spring mechanisms or the tips themselves.

Routine Inspection for Wear and Tear

Regularly inspect your probes for any signs of wear, such as bent tips, degraded plating, or diminished spring tension. A damaged probe can lead to inconsistent contact or even scratch the PCB surface, resulting in costly repairs. Should you identify any issues, replace the probe immediately to prevent compromising test accuracy. Maintaining a log of usage cycles can assist in predicting when a probe might require replacement based on its rated lifespan.

What Are the Testing Methods and Their Probe Compatibility?

Different functional testing methodologies for SMT PCBs often require specific types of probes. Understanding your chosen testing approach will guide your probe selection.

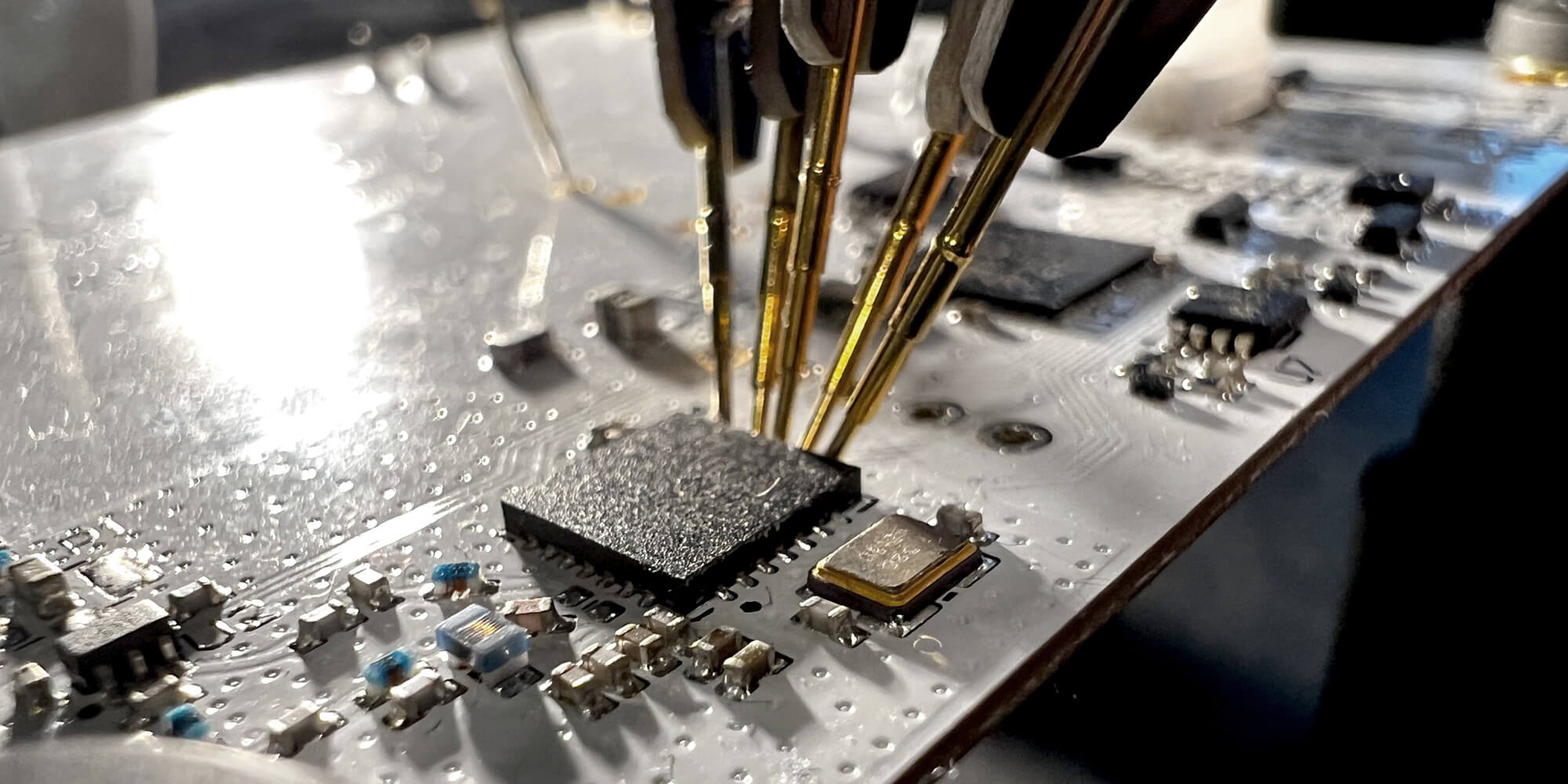

● In-Circuit Testing (ICT): This method frequently employs spring-loaded probes in a "bed-of-nails" fixture to simultaneously contact multiple test points. Probes for ICT must offer consistent spring force and low resistance to ensure accurate readings across the board.

● Flying Probe Testing: This technique uses movable probes to dynamically access test points. Due to the precision required to target small, closely spaced points without a fixed fixture, fine pitch probes are essential.

● Functional Testing (FCT): FCT focuses on the overall performance of the board under operational conditions. Probes for FCT must be capable of handling a diverse range of signal types and frequencies, necessitating both low resistance and high durability.

It's imperative to confirm that your chosen probes are fully compatible with both your testing equipment and the method you intend to use. For example, flying probe systems often require specific probe holders or connectors, so always check the system specifications before making a purchase.

Related Reading: What You Need to Know Before Designing an ICT Test Fixture

Practical Advice for Optimizing SMT Test Probe Selection

Developing a Comprehensive Test Plan

Begin by creating a detailed test plan that identifies the specific test points, pitch requirements, and signal characteristics of your PCB. This foundational step ensures that you select tools perfectly matched to your unique testing demands.

Investing in Versatility

If your work involves a diverse array of PCB designs, consider investing in modular probe systems. These systems typically offer interchangeable tips, allowing for adaptability across various applications without the need for multiple full probe sets.

Balancing Cost with Quality

While budgetary constraints are always a factor, prioritize quality over initial cost, especially for critical testing applications. Opting for cheaper probes might offer short-term savings but can lead to significant errors and expenses down the line due to unreliable performance.

Consulting with Suppliers

If you have uncertainties regarding probe compatibility or specific technical specifications, do not hesitate to reach out to your probe supplier. Their expertise can provide tailored recommendations best suited for your particular PCB design and testing setup.

Conclusion: Achieving Reliable SMT PCB Testing Through Smart Probe Choices

Selecting the appropriate test probes for functional testing of SMT PCBs is a multifaceted process that demands meticulous attention to detail and a clear understanding of your specific testing requirements. By carefully considering critical factors such as PCB test point size, fine pitch probe compatibility, test probe resistance, and implementing diligent probe maintenance, you can consistently achieve accurate and dependable results. High-quality probes, combined with consistent care and the application of the right testing methodologies, are fundamental to maintaining the integrity of your SMT assemblies and delivering superior electronic products.

At AIVON, we recognize the critical role of precision in every stage of PCB manufacturing and testing. Whether you are working with high-density SMT designs or navigating complex functional testing demands, choosing the correct tools is paramount. Utilize this guide as a strategic roadmap to make informed decisions about SMT test probes and significantly enhance the quality of your testing processes.