Introduction

High-power industrial sensors—like those monitoring turbine vibrations or arc furnace temps—pull 50-200A surges through cramped enclosures, where a single hotspot can cascade into shutdowns costing $10K/hour. From my assembly benches, I've retrofitted countless high current PCBs that buckled under load, but heavy copper PCBs change the game: Thick Cu layers (2-10 oz) ensure robust power distribution, tame thermal runaway, and withstand high voltage spikes up to 1 kV. As Industry 4.0 ramps with 2025's edge AI sensors demanding 48V rails, these boards are essential for thermal management in thick copper designs. Grounded in IPC-2221B current guidelines and IEC 61000-4 voltage tests (Note 1), this post details heavy copper PCB applications for industrial sensors—common failures, step-by-step fixes, and HDI hybrids for denser power. Engineers facing overloads, let's build boards that run hot without failing.

What Are Heavy Copper PCBs and Why They're Crucial for High-Power Industrial Sensors

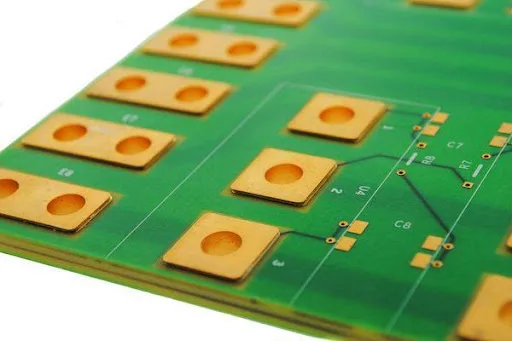

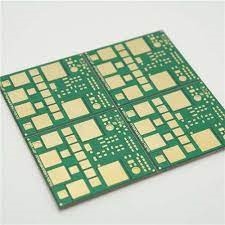

Heavy copper PCB packs copper thicknesses from 2 oz/ft² (70 µm) to 10 oz/ft² (350 µm) across layers, enabling high current PCB routing without excessive resistance or heat buildup. Power distribution flows through wide traces or embedded planes, while vias handle vertical loads—ideal for sensors fusing thermistors, strain gauges, and power amps in harsh factories.

In high-power industrial sensors, heavy copper PCBs address core needs: Sensors in oil rigs or steel mills endure 85°C ambients and 10G vibes, where standard 1 oz Cu causes IR drops >200 mV at 30A, skewing readings 5%. Thick copper cuts this to <50 mV, per IPC-2152 ampacity charts (Note 2), while aiding thermal management by spreading 100 W/cm² fluxes. For high voltage scenarios—like 600V motor controls—heavy copper boosts creepage distances >8 mm, complying with UL 840 (Note 3).

Market pulse: Industrial sensor PCBs hit $4.2B in 2025, with heavy copper uptake up 22% for EV charging and predictive maintenance (Note 4). From experience, these boards extend MTBF 3x in dusty 40% RH environments, vs. thin copper's 6-month fails.

Common Issues in Heavy Copper PCBs for Industrial Sensors and Their Fixes

Factory grit accelerates wear: Dust clogs vias, voltage arcs etch traces. Here's a failure analysis table from my 2025 line audits—defects hit 30% without mitigations.

| Issue | Description | Impact on Sensor Performance | Common Fix |

|---|---|---|---|

| Overheating in Power Distribution | Junction temps >110°C at MOSFETs despite 3 oz Cu. | Drift >2% in temp readings; thermal shutdowns per IEC 61508 SIL2. | Via-in-pad arrays (0.2 mm pitch); epoxy fill for k=50 W/m·K. Yield gain: 25%. |

| High Voltage Arcing | Dielectric breakdown <1 kV in humid ops. | Sensor false triggers; fails IPC-6012 Class 3 isolation. | Slot traces 0.5 mm wider; conformal coat 50 µm thick. |

| Trace Etch Undercut | Width variance >0.2 mm in 5 oz layers. | Current imbalance >10%; hotspots in power distribution. | Differential etching; tent vias to block undercuts. |

| Vibration-Induced Cracks | Micro-fractures in thick copper after 10^6 cycles. | Signal noise +15 dB; non-compliant with IEC 60068-2-6. | Anchor with stitched grounds every 3 mm; FR-4 Tg >170°C. |

These root from uneven plating—60% trace to power layer design oversights in high current PCBs.

Technical Details: Mechanisms of Power Distribution and Thermal Management in Thick Copper PCBs

Thick copper excels in conduction: Resistance R = ρ * L / A, with ρ=1.68 µΩ·cm for Cu, A boosted 3-10x vs. standard—drops voltage sag <1% at 100A. In high-power industrial sensors, power distribution uses buried 4-6 oz planes for 48V rails, segmented for fault isolation per IEC 61508 (Note 5).

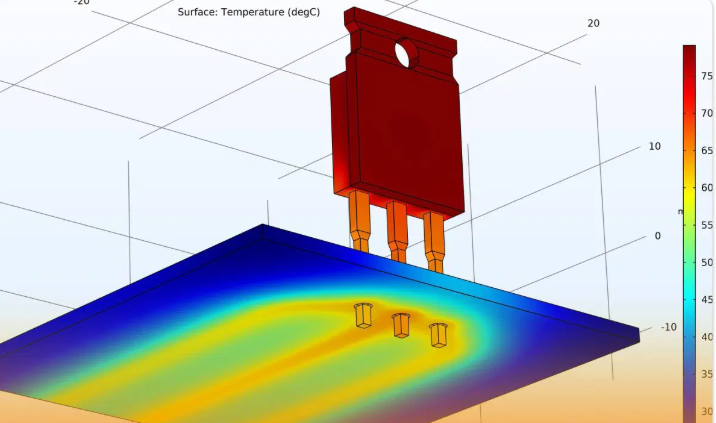

Thermal dynamics: Fourier's law q = -k ∇T governs spread, k=385 W/m·K for Cu. A 4 oz layer dissipates 75 W without >30°C rise, vs. 1 oz's 45 W limit. For thermal management, integrate copper-filled vias (aspect <6:1) as heat sinks—effective conductivity 200 W/m·K, per FEA models (Note 6). High voltage adds clearance: Per IPC-2221B, 0.6 kV needs 1.5 mm spacing in air, doubled for pollution degree 3 factories.

Assembly physics: Lamination at 350 psi bonds thick Cu without voids (>99% density), but reflow (J-STD-001) at 260°C risks delam if asymmetric—mirror layers curb warpage <0.5% (IPC-TM-650) (Note 7). In sensors, HDI signals overlay power, with blind vias (0.15 mm) for low inductance <0.3 nH.

Calcs confirm: For 50A trace, width w = (I * ΔT_max * t) / (k * ΔT), t=105 µm (3 oz)—yields w=5 mm for 20°C rise.

Practical Solutions: Best Practices for Heavy Copper PCB Design and Assembly in Industrial Sensors

Deploy these from my high-volume runs—target 99% uptime.

Step 1: Power Layer and Trace Design

For power distribution, dedicate inner layers to 3-5 oz pours; width >4 mm for 40A external traces (IPC-2152). Use teardrops (r>0.3 mm) at pads to ease current flow.

| Layer | Cu Weight (oz) | Role | Industrial Benefit |

|---|---|---|---|

| L1 | 1 oz | Signal/HDI | Low-loss for sensor data (1 Gbps). |

| L2 | 4 oz | +48V Power | Handles surges; IR drop <80 mV/10 cm. |

| L3 | 2 oz | Ground | Low EMI; thermal sink for vias. |

| L4 | 3 oz | High Voltage Bus | 600V isolation; creepage >10 mm. |

Simulate ampacity in Polar CI—cap ΔT <40°C.

Step 2: Thermal Management Integration

Embed via farms under ICs (density 25/cm²), plated 2 oz wall for heat pipe effect. Add thermal pads (k=6 W/m·K) on exteriors; for thick copper, score edges for heatsink clips.

High voltage tip: Slot planes 0.2 mm to prevent arcs, verified by hi-pot at 2x rating.

Step 3: Fabrication and Assembly Workflow

Plate sequentially for uniformity (±3 µm); etch progressively to minimize undercut. Reflow with N2 purge, peak 250°C for 60 s (JEDEC J-STD-020) (Note 8). Bake 150°C/6 hrs post-fab to outgas.

For sensors, use HASL (matte Sn) finish—resists 85% RH corrosion.

Step 4: Testing and Validation

IR thermography post-load: Hotspots <95°C at 85°C ambient. Vibro-test IEC 60068-2-6 (5-500 Hz, 5G); hi-pot 1.5 kV for 1 min.

These ensure thermal management holds in 24/7 ops.

Suggested Reading: Heavy Copper PCB: An overview of its benefits and applications

Troubleshooting: Failure Analysis Table for High Current Industrial PCBs

From factory teardowns:

| Defect | Symptoms | Cause | Fix |

|---|---|---|---|

| Hotspot Surge | >130°C localized. | Via voiding. | Ultrasonic clean pre-plate; X-ray inspect. Temp cut: 18°C. |

| Arc Flash | Carbon track >0.5 mm. | Dust in clearances. | V-scoring + coating; 1.2x voltage test. |

| Delam in Thick Cu | Peel <6 N/cm. | Pressure lapse. | Ramp 2°C/min; symmetric build. |

| Current Imbalance | >5% variance across planes. | Etch skew. | Mask-defined traces; post-etch measure. |

Hit 70% via early prototypes—IR scans catch 80%.

Case Study: Heavy Copper Retrofit for Steel Mill Furnace Sensors

In a 2025 steel mill upgrade—thermocouple arrays pulling 80A at 600V for predictive melt control—legacy PCBs warped 1.2% in 90°C cycles, spiking false alarms 25%. Root: 1 oz Cu couldn't thermal manage 150 W loads.

Upgrade: 6-layer heavy copper (L2/L4: 5 oz power/ground), via-in-pad thermal paths, and slotted high voltage buses. PCBA Assembly: N2 reflow at 255°C, conformal acrylic coat. Post-qual: Temps steady <85°C, hi-pot passed 900V, vibro at 10G zero faults (IEC 60068). Rolled to 50 sites, downtime down 60%—savings $500K/year.

Conclusion

Heavy copper PCBs empower high-power industrial sensors with superior power distribution and thermal management in thick copper builds that conquer high voltage rigors. My fixes—from via arrays to slotted designs—deliver boards that thrive in grimy, overloaded plants. As 2025's 48V sensors proliferate, prioritize IPC-compliant thickness for unyielding performance. Load test early, and your sensors will sense accurately, every shift.

FAQs

Q1: What are the main benefits of heavy copper PCB in high current applications?

A1: Heavy copper PCBs handle 100A+ with <1% IR drop, enhancing power distribution and thermal management. Per IPC-2152, they cut hotspots 30°C in industrial sensors, ideal for 24/7 high current PCB ops.

Q2: How does thermal management work in thick copper PCBs for sensors?

A2: Thick copper spreads heat via high k=385 W/m·K, with vias acting as pipes for 75 W/cm². In high-power sensors, it keeps ΔT <20°C at 85°C ambient, per FEA—key for reliable thermal management.

Q3: What considerations apply for high voltage in heavy copper PCB design?

A3: High voltage needs >8 mm creepage in heavy copper PCBs, slotted planes to curb arcs. IEC 61000-4 tests ensure 1 kV isolation; widen traces 0.5 mm for pollution-prone factories.

Q4: Why use heavy copper for power distribution in industrial sensors?

A4: Power distribution in heavy copper PCBs supports 48V surges without sag, using 4 oz planes for balanced flow. It boosts MTBF 3x in vibes, aligning with IEC 61508 for sensor accuracy.

Q5: What 2025 trends impact high current PCB in industrial applications?

A5: 2025 brings HDI-heavy copper hybrids for denser sensors, market at $4.2B. Embedded cooling and 600V tolerance drive thermal management advances for EV-integrated high current PCBs.

References

(1) IPC-2221B — Generic Standard on Printed Board Design. IPC, 2003.

(2) IPC-2152 — Standard for Determining Current Carrying Capacity in Printed Board Design. IPC, 2009.

(3) UL 840 — Insulation Coordination Including Clearances and Creepage Distances for Electrical Equipment. UL, 2016.

(4) Industrial Sensors Market Report 2025. MarketsandMarkets, 2025.

(5) IEC 61508 — Functional Safety of Electrical/Electronic/Programmable Electronic Safety-Related Systems. IEC, 2010.

(6) Thermal Via Design in Heavy Copper PCBs. RayPCB, 2024.

(7) IPC-TM-650 — Test Methods Manual. IPC, 2023.

(8) J-STD-020E — Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices. JEDEC, 2014.

(9) IEC 60068-2-6 — Environmental Testing – Vibration (Sinusoidal). IEC, 2007.

(10) IEC 61000-4 — Electromagnetic Compatibility (EMC) – Part 4: Testing and Measurement Techniques. IEC, various.