Introduction

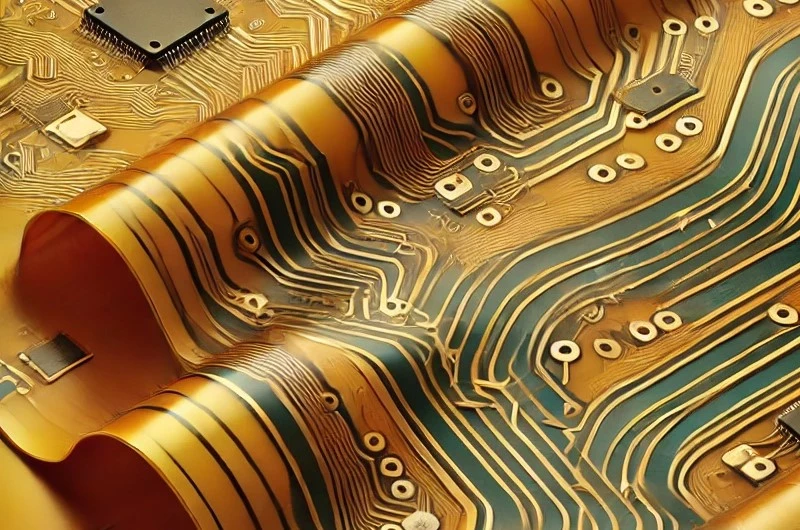

Flexible printed circuit boards (PCBs) play a critical role in modern electronics, enabling compact designs and dynamic applications across industries like aerospace, medical, and consumer electronics. The unique ability of flexible PCBs to bend and conform to various shapes stems from the specialized materials used in their construction. Among these, polyimide, polyester, and adhesives stand out as foundational components that define their performance, durability, and suitability for specific environments. Understanding these materials is essential for engineers aiming to design reliable and efficient flexible circuits. This article explores the properties, applications, and standards governing these materials, providing a comprehensive guide for electrical engineers seeking to optimize their flexible PCB designs with proven industry practices and technical insights.

What Are Flexible PCBs and Why Do Materials Matter

Flexible PCBs are thin, lightweight circuit boards that can bend, fold, or twist without compromising electrical functionality. Unlike rigid PCBs, they are built to withstand mechanical stress and fit into constrained spaces, making them ideal for wearable devices, automotive systems, and portable electronics. The choice of materials directly impacts their flexibility, thermal stability, and electrical performance. Poor material selection can lead to failures such as cracking, delamination, or signal loss. Polyimide, polyester, and adhesives are the primary materials that determine how well a flexible PCB performs under specific conditions. For electrical engineers, aligning material properties with application needs ensures reliability and longevity while adhering to established industry standards for quality and performance.

Core Materials in Flexible PCB Construction

Polyimide as a Base Material

Polyimide is the most widely used base material for flexible PCBs due to its exceptional thermal stability and mechanical strength. It can withstand temperatures exceeding 260 degrees Celsius, making it suitable for high heat environments like soldering processes or automotive applications. Polyimide also offers excellent chemical resistance and a low dielectric constant, ensuring minimal signal interference in high frequency circuits. Its flexibility allows for repeated bending without cracking, which is critical for dynamic flex applications.

This material is often employed in multilayer flexible designs where space and weight are constraints. Engineers value polyimide for its ability to maintain dimensional stability under stress, reducing risks of warpage or deformation during manufacturing or operation. Industry standards, such as IPC-6013D, provide guidelines for using polyimide in flexible circuits, ensuring consistent quality and performance across applications.

Polyester as an Alternative Substrate

Polyester, often referred to as PET in technical contexts, serves as a cost effective alternative to polyimide for less demanding flexible PCB applications. It offers decent flexibility and is lighter than polyimide, but its thermal resistance is limited, typically up to 150 degrees Celsius. This makes polyester suitable for low temperature environments, such as in consumer electronics like calculators or simple displays.

While polyester provides adequate electrical insulation, its mechanical durability is lower compared to polyimide, limiting its use in dynamic flexing scenarios. Engineers often select polyester for static flex applications where cost savings are prioritized over extreme performance. Adherence to standards like IPC-6013D ensures that polyester based flexible PCBs meet necessary quality benchmarks for their intended use.

Adhesives in Flexible PCB Assembly

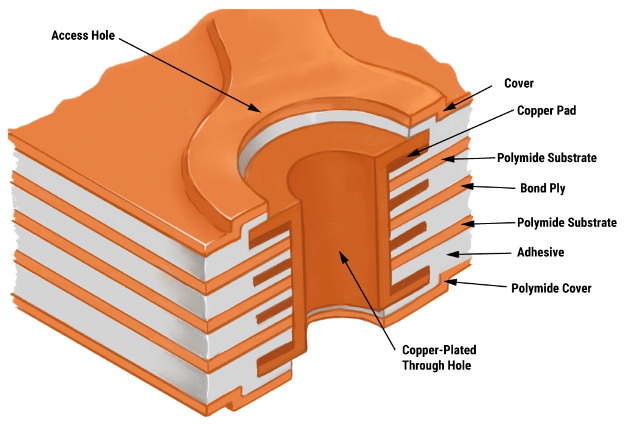

Adhesives are critical in bonding layers of a flexible PCB, securing copper foils to substrates like polyimide or polyester. They must maintain strong adhesion under bending stress and varying temperatures to prevent delamination. Common adhesive systems include acrylic and epoxy based formulations, chosen for their balance of flexibility and bonding strength. These adhesives also need to resist moisture and chemical exposure to protect the circuit integrity over time.

The choice of adhesive impacts the overall flexibility and reliability of the PCB. For instance, adhesives with high elasticity are preferred for dynamic flex applications to absorb mechanical stress. Standards such as IPC-6013D outline performance criteria for adhesives in flexible circuits, ensuring they meet durability and environmental resistance requirements for various applications.

Suggested Reading: Flexible PCBs: Materials, Fabrication, and Applications

Technical Properties and Selection Criteria

Comparing Polyimide and Polyester

When selecting between polyimide and polyester for flexible PCBs, engineers must evaluate key properties against application demands. Polyimide excels in thermal endurance and mechanical resilience, ideal for harsh environments like aerospace or industrial systems. Polyester, while less robust, suits budget constrained projects with moderate performance needs. The dielectric strength of polyimide is generally higher, supporting better signal integrity in high speed circuits compared to polyester.

A practical approach involves mapping material properties to environmental factors. For instance, if a device operates in a temperature range of 200 degrees Celsius, polyimide is the clear choice. Standards like IPC-6013D provide detailed specifications for material performance, guiding engineers in making informed decisions based on thermal, electrical, and mechanical criteria.

Role of Adhesives in Performance

Adhesives must complement the base material to ensure a cohesive structure in flexible PCBs. Their primary function is to maintain layer integrity during bending and thermal cycling. Poor adhesive selection can lead to separation of layers, causing electrical failures. Engineers assess adhesive properties like peel strength, shear strength, and thermal expansion compatibility with substrates to avoid such issues.

Testing adhesives under simulated conditions, as recommended by IPC-6013D, helps predict their behavior in real world scenarios. For high reliability applications, adhesives are often subjected to environmental stress tests to confirm their performance over time. This ensures the flexible PCB remains functional under mechanical and thermal loads.

For more knowledge about flexible and rigid-flex PCBs, see our comprehensive guide: Flexible and Rigid-Flex PCBs: The Complete Engineering Guide

Best Practices for Material Selection

Aligning Materials with Application Needs

Selecting materials for flexible PCBs starts with defining the application type, whether static or dynamic flex. Static flex applications, where the board is bent once during installation, can use polyester for cost efficiency. Dynamic flex, involving repeated bending, demands polyimide for its superior durability. Engineers should also consider operating temperature ranges and environmental exposure when choosing materials.

Adhesives must match the base material’s properties to avoid mismatched thermal expansion, which can cause stress fractures. Consulting standards like IPC-6013D provides a framework for matching materials to specific performance criteria, ensuring compatibility and reliability in the final design.

Adhering to Industry Standards

Industry standards are vital for ensuring material quality and consistency in flexible PCB production. IPC-6013D, for instance, specifies requirements for flexible printed boards, covering aspects like material selection, thermal stress testing, and bend cycle endurance. Following these guidelines helps engineers avoid common pitfalls such as material degradation or premature failure.

Additionally, standards like ISO 9001:2015 support quality management practices in material sourcing and manufacturing processes. Implementing these standards during design and production phases guarantees that polyimide, polyester, and adhesives meet rigorous performance benchmarks, reducing risks in critical applications.

Challenges in Using Flexible PCB Materials

Thermal and Mechanical Stress

Flexible PCBs often face thermal and mechanical stress during operation, challenging the integrity of materials like polyimide, polyester, and adhesives. High temperatures can weaken adhesive bonds, while repeated bending may cause micro cracks in substrates. Engineers must account for these factors by selecting materials with proven stress resistance, guided by standards such as IPC-6013D.

Mitigating these challenges involves rigorous testing of materials under simulated conditions. Thermal cycling tests and bend endurance evaluations help identify potential failure points before production. Choosing materials with compatible coefficients of thermal expansion minimizes stress at layer interfaces, enhancing overall reliability.

Environmental Factors

Environmental conditions like humidity, chemical exposure, and UV radiation can degrade flexible PCB materials over time. Polyimide offers better resistance to such factors compared to polyester, making it preferable for outdoor or harsh environment applications. Adhesives must also be selected for their ability to withstand moisture and chemical attack to prevent delamination.

Standards like IPC-6013D include test methods for environmental resistance, allowing engineers to validate material performance under specific conditions. Incorporating protective coatings or encapsulation can further enhance material durability, ensuring flexible PCBs maintain functionality in challenging environments.

Conclusion

Materials such as polyimide, polyester, and adhesives form the backbone of flexible PCB technology, enabling innovative designs in compact and dynamic electronic applications. Polyimide stands out for its thermal and mechanical superiority, while polyester offers a cost effective option for simpler needs. Adhesives play a crucial role in maintaining structural integrity under stress. By aligning material selection with application requirements and adhering to industry standards like IPC-6013D, engineers can design flexible PCBs that deliver reliability and performance. A thorough understanding of these materials empowers professionals to address design challenges and optimize outcomes in their projects.

FAQs

Q1: What makes polyimide a preferred material for flexible PCBs?

A1: Polyimide is favored for flexible PCBs due to its high thermal stability, enduring temperatures above 260 degrees Celsius, and excellent mechanical strength. It resists cracking during repeated bending, making it ideal for dynamic flex applications. Its low dielectric constant also supports high frequency circuits with minimal signal loss, ensuring reliability in demanding environments as outlined in standards like IPC-6013D.

Q2: How does polyester compare to polyimide in flexible PCB design?

A2: Polyester, often termed PET, is a cost effective alternative to polyimide for flexible PCBs, suitable for static flex applications. It handles temperatures up to 150 degrees Celsius but lacks the thermal and mechanical endurance of polyimide. While adequate for low demand consumer electronics, it falls short in harsh conditions, requiring careful selection based on application needs per IPC-6013D guidelines.

Q3: Why are adhesives critical in flexible PCB manufacturing?

A3: Adhesives are vital in flexible PCBs for bonding layers like copper foils to substrates, ensuring structural integrity during bending. They must resist thermal and mechanical stress to prevent delamination. Proper adhesive selection, matching the substrate’s properties, maintains circuit reliability. Standards like IPC-6013D provide criteria for testing adhesive performance under various conditions for consistent quality.

Q4: What standards govern the use of materials in flexible PCBs?

A4: Industry standards such as IPC-6013D outline requirements for materials like polyimide, polyester, and adhesives in flexible PCBs. They cover thermal stress, bend endurance, and environmental resistance to ensure quality. Additionally, ISO 9001:2015 supports consistent material sourcing and manufacturing practices, helping engineers achieve reliable designs through standardized processes and testing protocols.

References

IPC-6013D — Qualification and Performance Specification for Flexible and Rigid-Flex Printed Boards. IPC, 2017.

ISO 9001:2015 — Quality Management Systems. ISO, 2015.