SMT Stencil Materials Face Off: Stainless Steel vs. Nickel – Which Reigns Supreme?

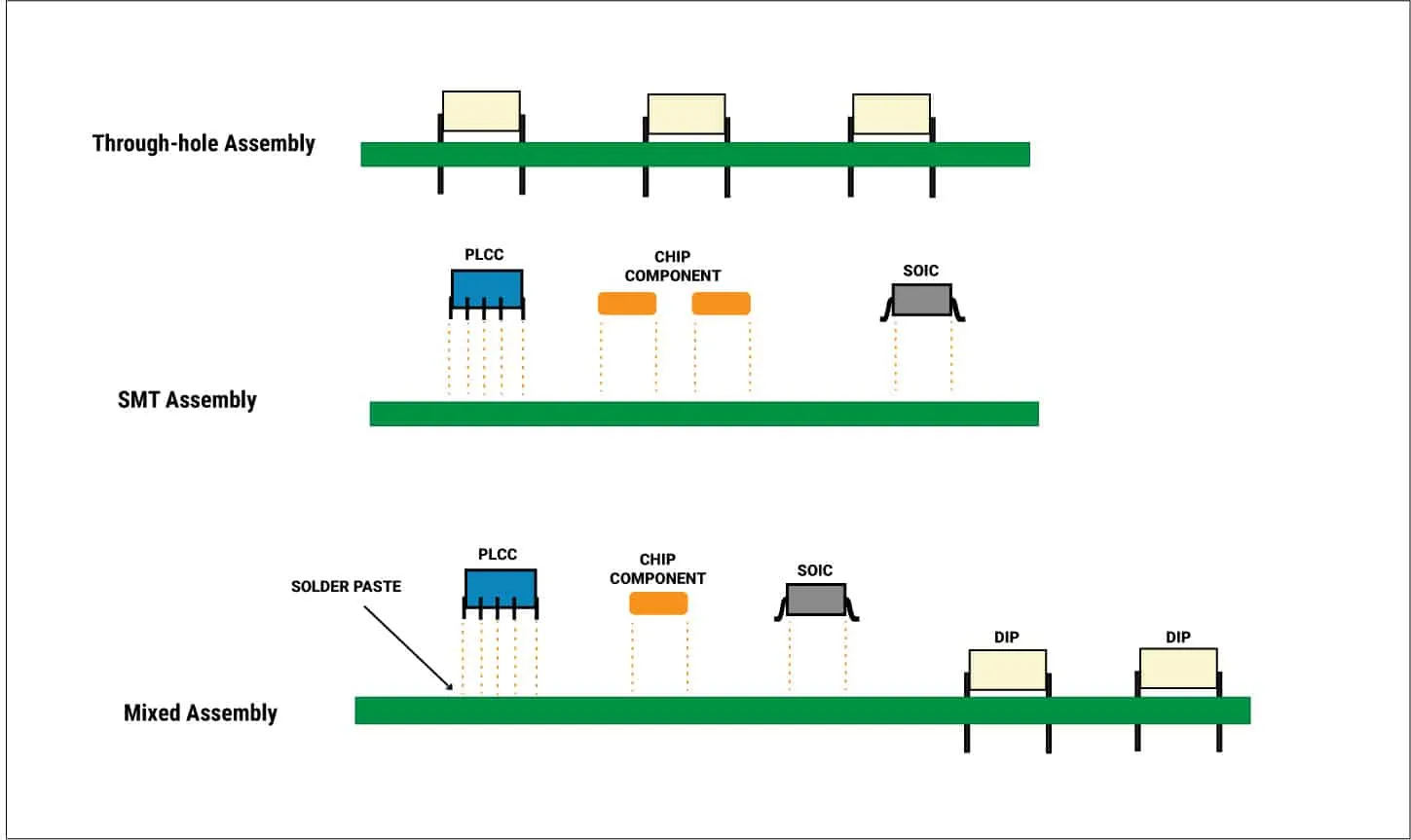

Compare stainless steel SMT stencils and nickel SMT stencils for durability, cost, paste release, and precision. Practical insights help PCB engineers select the best material for fine-pitch or high-volume assembly to improve yields and reduce defects.